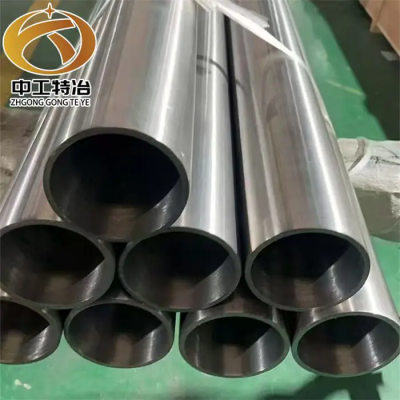

From China Factory Supply Ss 301 304 316 321 Welded Pipe Seamless Stainless Steel Pipe

From China Factory Supply: SS 301, 304, 316, 321 Welded and Seamless Stainless Steel Pipes

1. Product Overview

Our factory in China takes pride in offering a wide range of stainless steel pipes, including SS 301, 304, 316, and 321. These pipes come in both welded and seamless options, catering to diverse industrial and commercial needs. Stainless steel pipes are known for their exceptional durability, corrosion resistance, and versatility, making them an ideal choice for various applications across the globe.

2. Material Specifications

SS 301

- Composition: SS 301 is a chromium - nickel austenitic stainless steel. It typically contains around 17% chromium and 7% nickel.

- Properties: This grade offers good ductility and formability, which makes it suitable for applications that require bending and shaping. It also has a relatively high strength, especially when cold - worked.

SS 304

- Composition: With approximately 18% chromium and 8% nickel, SS 304 is one of the most widely used stainless steel grades.

- Properties: It provides excellent corrosion resistance in a variety of environments, including mild chemical and food - processing applications. It is also highly weldable and has good mechanical properties.

SS 316

- Composition: SS 316 contains 16 - 18% chromium, 10 - 14% nickel, and 2 - 3% molybdenum.

- Properties: The addition of molybdenum enhances its corrosion resistance, especially in chloride - rich environments such as marine applications. It is more resistant to pitting and crevice corrosion compared to SS 304.

SS 321

- Composition: SS 321 has a similar composition to SS 304 but with the addition of titanium.

- Properties: Titanium stabilizes the steel against intergranular corrosion when exposed to high temperatures. This makes SS 321 suitable for applications in high - temperature environments, such as in heat exchangers and exhaust systems.

3. Welded vs. Seamless Pipes

Welded Pipes

- Manufacturing Process: Welded stainless steel pipes are produced by rolling a flat stainless steel sheet into a tubular shape and then welding the seam. This process allows for the production of pipes in various sizes and lengths.

- Advantages: They are generally more cost - effective than seamless pipes, especially for larger diameters. Welded pipes can also be produced with a smooth inner surface, which is beneficial for fluid - carrying applications.

Seamless Pipes

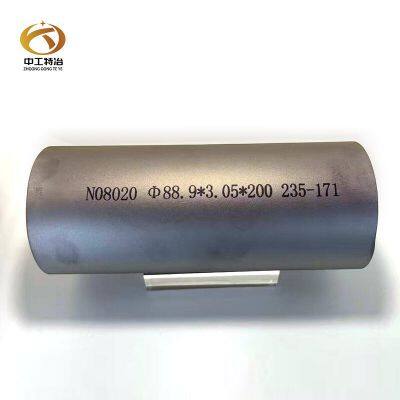

- Manufacturing Process: Seamless pipes are made by piercing a solid billet of stainless steel to create a hollow tube. This results in a pipe with a uniform wall thickness and no weld seam.

- Advantages: Seamless pipes offer higher strength and better resistance to pressure and corrosion compared to welded pipes. They are often preferred for applications where reliability and safety are critical, such as in high - pressure pipelines.

4. Surface Treatment

All our stainless steel pipes undergo a complete surface treatment process. This includes processes such as pickling, passivation, and polishing. The pickling process removes impurities and scale from the surface of the pipes, while passivation forms a protective oxide layer that enhances corrosion resistance. Polishing can be done to achieve a smooth and aesthetically pleasing finish, which is suitable for applications where appearance is important.

5. Applications

- Construction: Stainless steel pipes are widely used in the construction industry for structural support, handrails, and plumbing systems. Their corrosion resistance ensures long - term durability in different weather conditions.

- Chemical and Petrochemical Industries: The excellent corrosion resistance of SS 316 and other grades makes them ideal for transporting chemicals, acids, and other corrosive substances.

- Food and Beverage Industry: SS 304 and SS 316 pipes are commonly used in food - processing and beverage - production facilities due to their hygienic properties and resistance to food - related corrosion.

- Automotive and Aerospace Industries: Seamless stainless steel pipes are used in exhaust systems, fuel lines, and other components where high strength and reliability are required.

6. Company Background

Our company, established in 2022, is a manufacturer based in China. We have a rich history in the metal materials industry. Since 1999, we have been expanding our business, starting from a metal material sales office in Beijing and later establishing offices in Tianjin and Wuxi. We have an overseas office and an export share of above US$100 Million. Our company holds the ISO9001 production certification, which guarantees the quality of our products.

7. Company Services

- Product Information and Sample Supply: We provide customers with detailed product information, including specifications, features, and uses. We also offer samples for customers to evaluate and confirm the quality of our products.

- Price and Negotiation: We provide quotations based on customer needs, including price, delivery terms, and payment methods. We are open to price negotiation to reach a mutually satisfactory agreement.

- Order Processing: We accept customer orders and ensure accurate processing. We confirm order details such as quantity, model, and delivery time to avoid any misunderstandings.

- Production Follow - up and Quality Control: We closely follow up on the production progress to ensure timely delivery. Our quality control team conducts strict inspections to ensure that the products meet customer requirements and international standards.

- Logistics Arrangement: We arrange transportation and logistics, including shipping, choosing the appropriate transportation mode (sea freight, air freight, etc.), and handling customs clearance procedures. We track the transportation of goods to ensure they arrive at the customer's designated location smoothly.

- After - Sale Service: We handle customer complaints and issues promptly to ensure customer satisfaction. Our customer service team is available 24 hours a day to provide support.

8. Company Team

Our company has a professional team in different aspects. The technical team consists of sales elites who are proficient in the specialized knowledge of special alloys. They can quickly explain the professional knowledge of our products to customers and promote product iteration and upgrading. The market and sales team accurately grasps market dynamics and effectively expands our market share. The customer service team puts customers at the center, providing 24 - hour uninterrupted high - quality service. We also encourage innovation, collaboration, learning, and a sense of responsibility within our team to ensure the best service for our customers.

Send Inquiry to This Supplier

You May Also Like

-

Cold Rolled/Hot Rolled AISI 4130 4140 Rolled Stainless Steel Seamless/Round Tube/Welded PipeNegotiableMOQ: 1 Ton

-

Stainless Steel Pipe Manufacturer Stainless Steel 304 316l 904 Pipe 300 Series Alloy for IndustryNegotiableMOQ: 1 Ton

-

Factory Suppliers 201 304 304L 316 316L 430 436 439 409L 904L 310S 2205 2507 Stainless Steel Pipes Tubes PriceNegotiableMOQ: 1 Ton

-

Wholesale 201 304 316 Polished Round Stainless Steel Pipe Inox Manufacturer for Roofing Outdoor Decoration in ChinaNegotiableMOQ: 1 Ton

-

Factory Suppliers Prime Quality 304 304L 316 316L Stainless Steel Tube / Ss Pipe With Low PriceNegotiableMOQ: 1 Ton

-

304 Square Pipe Tp304 Stainless Steel Pipe 06cr19ni10 Welded Pipe 304L Sanitary Stainless Steel Seamless PipeNegotiableMOQ: 1 Ton

-

Stainless Steel Pipe Stainless Steel Square/Rectangular Pipe/Tube Ss Pipe 304 Stainless Steel TubeNegotiableMOQ: 1 Ton

-

High Quality Stainless Steel Square Tube, Rectangular Steel Tube Seamless Tube 304 316 321 Complete StockNegotiableMOQ: 1 Ton

-

Hot /Cold Rolled Stainless Steel/Gi Gl Seamless/Welde Square Steel Tube PipeNegotiableMOQ: 1 Ton

-

Square Rectangular Stainless Steel Tubes Hot Rolled 304 Square PipeNegotiableMOQ: 1 Ton