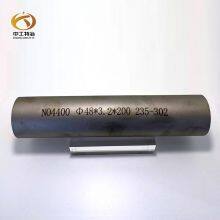

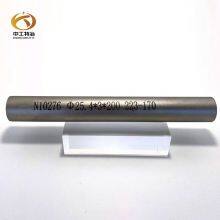

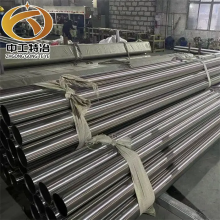

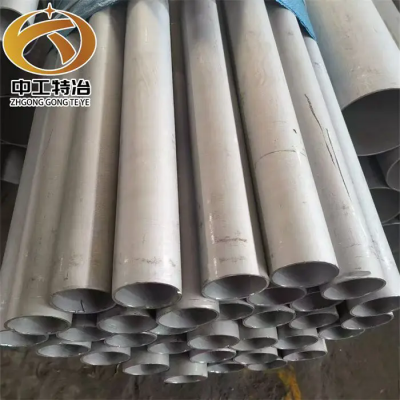

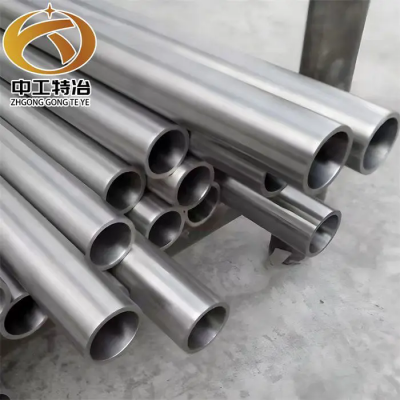

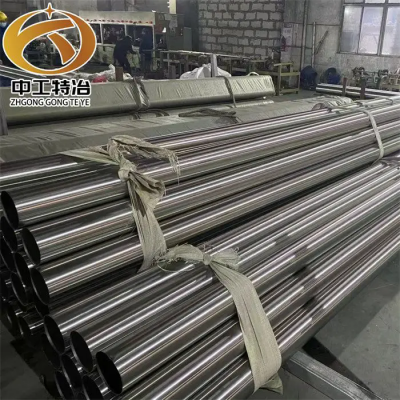

Round Inox Tube Brushed/Mirror Polished 201 304 Stainless Steel Welded Pipe

Product Overview

Our Round Inox Tube is a top - notch product crafted from high - quality 201 and 304 stainless steel. These tubes are available in both brushed and mirror - polished finishes, offering a wide range of aesthetic and functional options for various applications. The welded pipes are produced using advanced techniques, ensuring durability and reliability.

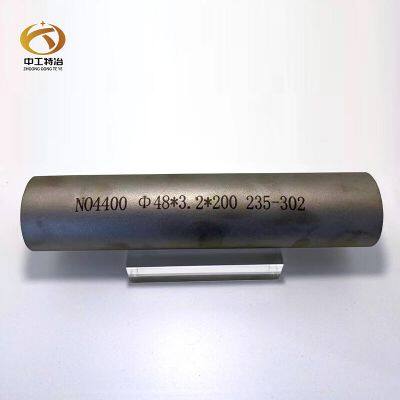

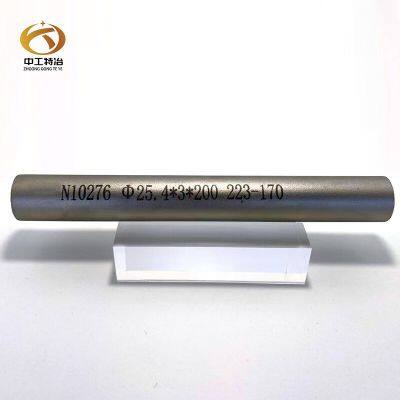

Material and Composition

- 201 Stainless Steel: This grade of stainless steel contains a balanced composition of elements. It has a relatively high manganese content, which gives it good strength and formability. 201 stainless steel is cost - effective, making it an ideal choice for applications where budget is a concern. It also offers decent corrosion resistance, suitable for indoor and some mild outdoor environments.

- 304 Stainless Steel: Renowned for its excellent corrosion resistance, 304 stainless steel is a popular choice in many industries. It contains chromium and nickel, which form a passive oxide layer on the surface of the tube. This layer protects the metal from rust and corrosion, even in harsh conditions such as exposure to moisture, chemicals, and high - humidity environments.

Surface Treatment

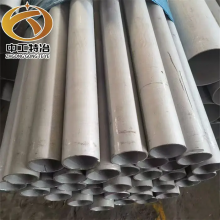

- Brushed Finish: The brushed surface treatment gives the tube a matte, textured appearance. It not only adds a touch of elegance but also has practical benefits. The brushed finish helps to hide minor scratches and fingerprints, making it a great option for applications where the tube will be frequently handled or in high - traffic areas.

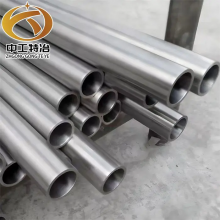

- Mirror - Polished Finish: A mirror - polished tube has a highly reflective surface that provides a sleek and modern look. It is perfect for applications where aesthetics are of prime importance, such as in architectural designs, decorative elements, or high - end furniture. The mirror finish also enhances the corrosion resistance of the tube by providing a smooth surface that is less likely to trap dirt and moisture.

Manufacturing Techniques

Our tubes are manufactured using both hot - rolling and cold - rolling techniques.

- Hot - Rolling: This process involves heating the stainless steel to a high temperature and then rolling it into the desired shape. Hot - rolling allows for the production of tubes with large diameters and thick walls. It also improves the mechanical properties of the steel, such as its ductility and toughness.

- Cold - Rolling: Cold - rolling is performed at room temperature. It results in a more precise dimensional accuracy and a smoother surface finish compared to hot - rolling. Cold - rolled tubes are often used in applications where tight tolerances are required, such as in precision machinery or automotive components.

Applications

- Architectural and Construction: Our round inox tubes are widely used in architectural projects. They can be used for handrails, balustrades, columns, and decorative facades. The variety of finishes allows architects and designers to create unique and visually appealing structures.

- Industrial Applications: In the industrial sector, these tubes are used in machinery, equipment, and pipelines. Their corrosion resistance and strength make them suitable for transporting various fluids and gases, as well as for structural support in manufacturing plants.

- Furniture and Interior Design: The tubes are also popular in the furniture industry. They can be used to make chairs, tables, shelves, and other furniture pieces. The brushed or mirror - polished finish adds a modern and stylish touch to the furniture.

- Automotive and Transportation: In the automotive and transportation industries, our tubes can be used for exhaust systems, chassis components, and decorative trim. The corrosion resistance of 304 stainless steel ensures long - term performance in harsh driving conditions.

Quality Assurance

We are a manufacturer with a strong commitment to quality. Our company, established in 2022, has obtained the ISO9001 production certification. This means that every step of the manufacturing process, from raw material selection to the final product inspection, is strictly controlled to ensure that the tubes meet the highest quality standards. Our technical team, composed of sales elites with in - depth knowledge of special alloys, continuously promotes product iteration and upgrading. They are able to quickly explain the professional knowledge of the products to customers, ensuring that customers have a clear understanding of the product's features and performance.

Company Services

- Product Information and Sample Supply: We provide customers with detailed product information, including specifications, features, and uses. We also offer samples for customers to evaluate and confirm the quality and suitability of the product.

- Price and Negotiation: Based on customer needs, we provide a comprehensive quotation that includes price, delivery terms, and payment methods. We are open to price negotiation to reach a mutually satisfactory agreement.

- Order Processing: We accept customer orders and process them with great care to ensure accuracy. We confirm all order details, such as quantity, model, and delivery time, to avoid any misunderstandings.

- Production Follow - up and Quality Control: We closely follow up on the production progress to ensure timely delivery. Our quality control team conducts strict inspections at every stage of production to ensure that the product meets customer requirements and standards.

- Logistics Arrangement: We take care of all transportation and logistics arrangements, including shipping, selection of the appropriate transportation mode (sea freight, air freight, etc.), and customs clearance procedures. We also track the transportation of goods to ensure that they arrive smoothly at the customer's designated location.

- After - Sale Service: We handle customer complaints and issues promptly to ensure customer satisfaction. Our customer service team is available 24 hours a day to provide high - quality service and support.

With our high - quality Round Inox Tube, comprehensive company services, and strong commitment to quality, we are confident that we can meet the diverse needs of international buyers. Whether you are in North America, South America, Europe, Asia, Africa, or Oceania, we are ready to serve you.

Send Inquiry to This Supplier

You May Also Like

-

Durable 304 and 316 Stainless Steel Pipe for Various ApplicationsNegotiableMOQ: 1 Ton

-

304 316L Compression Stainless Steel Pipe Factory Hospital Use ASTM StandardNegotiableMOQ: 1 Ton

-

China Stainless Steel 304L Welded Seamless Perforated Dairy Inox Tube Tubing PipeNegotiableMOQ: 1 Ton

-

From China Factory Supply Ss 301 304 316 321 Welded Pipe Seamless Stainless Steel PipeNegotiableMOQ: 1 Ton

-

ASTM AISI Corrision Resistant Stainless Steel Custom Size High Quality Stainless Steel PipeNegotiableMOQ: 1 Ton

-

Industrial ASTM A312 A213 TP304 316 316L 310S 321 No. 1 Finish Stainless Steel PipeNegotiableMOQ: 1 Ton

-

High Strength 316L Stainless Steel Pipe for Marine EngineeringNegotiableMOQ: 1 Ton

-

Stainless Steel Pipe Factory Direct Sale 201 304 310 Hot Roll/Cold Roll Steel TubeNegotiableMOQ: 1 Ton

-

304 316 409 Welded Stainless Steel Pipe Tube Manufacturer With Factory PriceNegotiableMOQ: 1 Ton

-

Cold Rolled/Hot Rolled AISI 4130 4140 Rolled Stainless Steel Seamless/Round Tube/Welded PipeNegotiableMOQ: 1 Ton