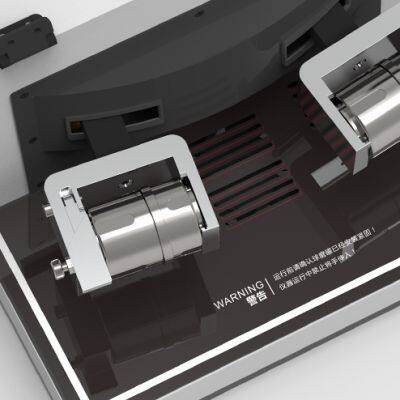

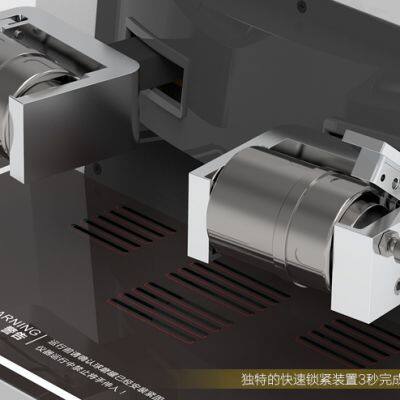

MM400 is used for rapid grinding or mixing of small amounts of dry, wet, and frozen samples in the laboratory. It is equipped with two 50ml ball milling tanks and can also be configured with various cell wall breaking adapters for biological cell wall breaking, DNA/RNA, and protein extraction. Its compact structure design, simple appearance, desktop operation, and small size use a variable frequency LCD screen control interface to achieve multiple functions such as timing, speed regulation, and intermittent grinding. The settings are simple and fast, and the display is intuitive. It can be started in a few minutes with one click to complete sample processing. It is safe and stable, and can be widely used for hard, medium low hardness, brittle, dry, viscous, fibrous, soft, and elastic samples;

Product Name: Mixed Tissue Grinding Machine

Model: MM400

Processing principle: Impact force | Friction force

Application sample characteristics: hard | medium to low hardness | brittle | dry | viscous | fibrous | soft | elastic

Processing Type: Crushing | Mixing | Homogenization | Cell Crushing | Freezing Grinding

Suggested maximum injection size:<8 mm

Sample size range:~5 um

Grinding method: dry grinding | wet grinding | low-temperature grinding

Grinding platform (number of cans): 2

Motion mode: planar arc-shaped reciprocating motion

Vibration frequency: 180-1800 r/min

Main functions: continuous operation | intermittent operation | timing | speed regulation | data storage | power-off memory | overload protection

Control mode: LCD screen display

Time setting: 59:59:59 (h/m/s)

Material of ball milling jar: tungsten carbide | zirconia | stainless steel | MC nylon | polytetrafluoroethylene, etc

Ball milling jar capacity: 50ml | 30ml

Sealing method of ball mill jar: sealing ring+threaded fastening

Grinding ball size: 1-25m optional

Grinding ball material: tungsten carbide | zirconia | agate | stainless steel

Cell wall breaking adapter volume: 10x0.2ml | 5x2ml | 5x5ml

Electrical description: 100-120V/200-240V AC, 50-60Hz, 150W

Power ports: National standard | European standard | American standard | British standard, etc

Net weight: 48 kg

Dimensions (length, width, height): 470 * 360 * 250

Protection level: IP63

Send Inquiry to This Supplier

You May Also Like

-

Soil Planetary Ball Mill Grinding and Screening InstrumentNegotiableMOQ: 1 Piece

-

Ultrasonic Planetary Ball MillNegotiableMOQ: 1 Piece

-

QM-2SP100 Planetary Ball Mill (25L x 4 Tanks)NegotiableMOQ: 1 Piece

-

MSK-SFM-3 High-speed Three-dimensional Vibration Ball MillUS$ 2000MOQ: 1 Piece

-

MM600 Nano High Energy Vibration Ball MillUS$ 6200MOQ: 1 Piece

-

Frozen High-throughput Tissue Grinder for Multiple SamplesUS$ 2680MOQ: 1 Piece

-

Multi Sample High-throughput Tissue GrinderUS$ 1500MOQ: 1 Piece

-

J-GT48 High-throughput Tissue GrinderUS$ 1660MOQ: 1 Piece

-

QM-3SP04 Ball Mill(0.4L)US$ 1660MOQ: 1 Piece

-

QM-3SP2 Ball Mill(2L)US$ 1980MOQ: 1 Piece