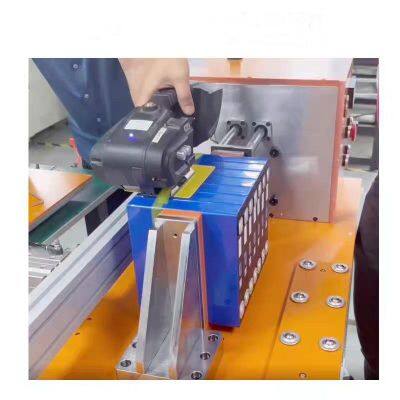

Aitop Prismatic Batteries Stacking Strapping Pressing PVC Strip Squeezing and Bundling Machine for Prismatic Battery Automatic Assembly Line

Battery Analyzer Capacity Tester

AITOP 5v3a6a10a20a30a50a60a100a Capacity Tester 8ch 5v100a Battery Capacity Tester battery charge discharge testerOne-year warranty and lifetime maintenance are our guarantee of quality .

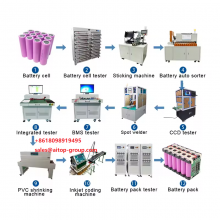

Our products including:

1.IR tester

2.Capacity tester for cylindrical &prismatic&polymer cells

3.BMS tester

4.Sorting machine for common use

5.Insulation paper sticker machine

6.Manual spot welding machine

7.Automatic spot welding machine

8.Battery pack integrated tester

9.Battery pack charging discharging aging machine

10.PVC shrinking machine

11. Nickel plate&PVC cutting machine

12.Laser welding machine

13.Wire bonding machine and etc.

All of our products are good price.

If you have any interesting,please feel free to contact with us

TOP Battery machine factory contact number

Shenzhen AITOP Intelligent Equipment Co., Ltd.

Email :sales(@)

wehcat/whatsapp /Phone Number:/+8618098919495

Performance characteristics

full charge and discharge curve of all channels, and can also be separated from the upper

computer and complete the operation through the control panel. Constant current constant voltage

charge, constant current discharge test, time sorting and other work.ETC

Contact us :

Shenzhen AITOP Intelligent Equipment Co. LTD

Sales Manager

Phone/Whatsapp/Wechat:008618520989583/008618435204981/

008618098989643/+8618820281861

Email:sales(@)

Packing and shipping

*Be Packed by Wooden Box

*Lead Time: Standard Machine: 7-10 working days after we received your battery pack samples.

*Customized Machine: 15-30 days

Our Service

Pre-sales

1) Inquiry and consulting support. All will be replied in 12 hours.

2) View our Factory and testing the machine, demonstrate how the machine work.

After-Sales

1) Training how to install the machine, training how to use the machine.

2) Engineers available to service machinery overseas

3) 1-year guarantee ( free maintain in ONE year(12 MONTH))

4) Replacement parts and other accessories provided

Send Inquiry to This Supplier

You May Also Like

-

AITOP Energy Regeneration Cell Grading Machine Energy Saving 5V 20A 512CH 18650-33140 Battery Capacity Tester Cycler TesterUS$ 5400 - 11800MOQ: 1 Piece

-

Aitop Cell Tester Energy Saving 5V 60A 64CH Prismatic, Pouch & Cylindrical With Cycle TestingUS$ 9900 - 100000MOQ: 1 Piece

-

18650 Battery Capacity Charge Discharge Tester Energy Storage Power High-precision 21700 Battery Aging 512ch Capacity TesterUS$ 3000 - 6000MOQ: 1 Piece

-

Energy Regeneration 18650 Cycler Tester 512 Channel Battery Capacity Charge Discharge Tester Aging Cabinet Battery Capacity Detection TesterUS$ 1000 - 10800MOQ: 1 Piece

-

Energy Saving 5V 60A 5V100A 4 Channel Battery Testing Tester Energy Efficient European Battery Charge Discharge Cycler for Life Cycle TestsUS$ 1000 - 1250MOQ: 1 Piece

-

Lab 5V50A 4Ch European High-Precision Energy Feedback Battery Test System Reduced Energy Comsumption Battery TesterUS$ 1000 - 1500MOQ: 1 Piece

-

Energy Regeneration 18650 Cycler Tester 5V6a 512CH Channel 21700 Cell Capacity Tester Charge Discharge Lithium Battery Grading Testing MachineNegotiableMOQ: 1 Piece

-

Energy Regeneration 5v3a 5a 6a10a 512 Channel Battery Fast Fixture Stable Reliable Capacity Tester Feedback Type for 33140 32140 40135NegotiableMOQ: 1 Piece

-

AITOP 512 Channels 5v 3a 5a 6a 10a Lithium Cylindrical Battery Capacity Tester For Industrial Machinery & Battery Production LineUS$ 2000 - 10000MOQ: 1 Piece

-

AITOP Capacity Tester C512 Channels 32650/18650 Battery charging&Discharging AnalyzerUS$ 3000 - 4200MOQ: 1 Piece