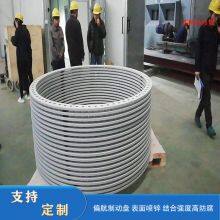

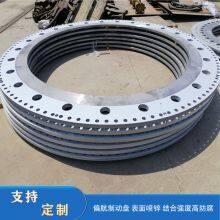

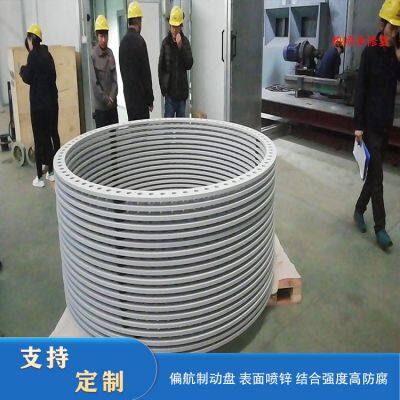

As a key component of fan, yaw brake disc is exposed to harsh environment for a long time, facing challenges such as corrosion and wear, which directly affects fan operation efficiency and life. Zinc spraying process, as an efficient means of protection, provides strong protection for the yaw brake disc. It is a process in which zinc wire or zinc powder is heated to a molten or semi-molten state by thermal spraying technology, and is sprayed to the surface of the substrate by high-speed air flow to form a dense zinc coating. This process is widely used in the field of metal surface protection, especially in harsh environments, showing excellent performance, becoming the choice of more and more manufacturers.

Advantages of zinc spraying process:

Excellent anti-corrosion performance: Zinc layer as a sacrificial anode, preferential corrosion, effectively protect the base metal, significantly extend the service life of the brake disc.

Excellent adhesion: The zinc spray layer is firmly combined with the matrix, and is not easy to flake off, ensuring long-term protection effect.

Good wear resistance: moderate hardness of zinc layer can effectively resist wear during braking and reduce maintenance costs.

Environmental protection and high efficiency: zinc spraying process is pollution-free, and the construction efficiency is high, suitable for mass production.

Jinan Tianmeng has been deeply engaged in the field of thermal spraying for many years, and we know the importance of zinc spraying process. We use advanced zinc spraying equipment and technology to strictly control each process to ensure stable and reliable quality of zinc spraying layer. Choose Jinan Tianmeng Technology Co., LTD., you will get quality repair services and good use experience. We look forward to working with you to protect your equipment together!

Send Inquiry to This Supplier

You May Also Like

-

Papermaking Drying CylinderUS$ 50MOQ: 1 Square Meter

-

Papermaking Drying Cylinder Accessories And Papermaking Scraper Are Available in Various ModelsUS$ 220MOQ: 1 Metric Ton

-

Jinan Thermal Spraying Plasma Processing of Silicon Carbide CoatingNegotiableMOQ: 1000 Square Meters

-

Surface Repair of the Rewinding Machine RollerUS$ 50MOQ: 1 Square Meter

-

Machine Industry Fluidized Bed Thermal Spraying Processing Teflon Preparation Anti-corrosion Wear-resistant Can Support CustomizedNegotiableMOQ: 1 Square Meter

-

Surface Treatment of Filter Core Plate Using Plasma Technology for Corrosion Prevention, Wear Resistance, and High Temperature ResistanceNegotiableMOQ: 1 Square Meter

-

Surface Treatment of Machinery Industry Thermal Spraying Plasma Process Anti-corrosion, Wear-resistant and Thermal InsulationCNY 268 - 468MOQ: 1 Square Meter

-

Surface Treatment in the Mechanical Industry, Spraying Tungsten Carbide for Corrosion Prevention and Wear ResistanceNegotiableMOQ: 1 Square Meter

-

Directly Supplied by the Manufacturer for Laser Cladding Surface Treatment, Piston Rod Surface Repair, Anti-corrosion and Wear-resistantNegotiableMOQ: 1 Square Meter

-

Repair of the Surface of the Drying Cylinder by Spraying Tungsten Carbide+Teflon Anti-corrosion and Wear-resistant Non Stick CoatingNegotiableMOQ: 1 Square Meter