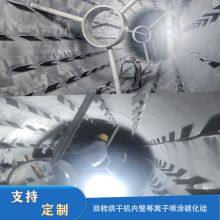

Jinan Thermal Spraying Plasma Processing of Silicon Carbide Coating

Plasma-sprayed silicon carbide has extremely high wear resistance. During the operation of the rotary dryer, the friction between the material and the inner wall can cause wear on the inner wall. However, the hardness of silicon carbide enables it to effectively resist this wear and extend the service life of the equipment.

Silicon carbide has excellent high-temperature resistance. During the high-temperature drying process, the inner wall material needs to withstand the challenge of high temperatures, while the plasma-sprayed silicon carbide can maintain its physical and chemical properties stable in a high-temperature environment, ensuring the efficient progress of the drying process.

3. Plasma spraying technology can form a uniform and dense coating, reducing the porosity of the inner wall, thereby lowering the adhesion of the material during the drying process and enhancing the drying efficiency.

When choosing thermal spraying processing, enterprises should consider multiple factors, including the wear resistance of the material, high-temperature resistance, uniformity of the coating, and processing costs, etc. Enterprises can choose the thermal spraying solution that best suits their production needs.

The advantages of the inner wall of the plasma spray carbonization rotary dryer are obvious. Its wear resistance, high-temperature resistance and excellent coating properties make it an ideal choice for enhancing the performance of dryers. Choosing the appropriate thermal spraying processing can not only improve the utilization efficiency of the equipment, but also reduce maintenance costs, bringing greater economic benefits to the enterprise.

Send Inquiry to This Supplier

You May Also Like

-

Directly Supplied by the Manufacturer for Laser Cladding Surface Treatment, Piston Rod Surface Repair, Anti-corrosion and Wear-resistantNegotiableMOQ: 1 Square Meter

-

Repair of the Surface of the Drying Cylinder by Spraying Tungsten Carbide+Teflon Anti-corrosion and Wear-resistant Non Stick CoatingNegotiableMOQ: 1 Square Meter

-

Surface Repair of the Mechanical Industry, Multi Section Roller, Supersonic Spraying Processing, Tungsten Carbide Coating, Wear-resistant and Anti-corrosionNegotiableMOQ: 1 Square Meter

-

Boiler Surface Repair and Spraying of Nano Ceramic Coating for Anti-corrosion and Wear PreventionNegotiableMOQ: 1 Square Meter

-

Support Customized Mechanical Sliding Rails for Laser Melting Surface Repair, Anti-corrosion and Wear-resistantNegotiableMOQ: 1 Square Meter

-

Ceramic Coating Scraper, Coating Scraper, Paper Coating Roller and Other Mechanical Scraper ProductsNegotiableMOQ: 1 Square Meter

-

Surface Repair and Aluminum Spraying Treatment Process for Mechanical Valves in the Source FactoryNegotiableMOQ: 1 Square Meter

-

Roller Surface Repair Using Spray Welding Process NI60 Coating Wear-resistant and Anti-corrosion PreparationNegotiableMOQ: 1 Square Meter

-

Mechanical Industry Supersonic Spray Machining Spiral Shaft Surface Repair, Spraying Anti-corrosion and Wear-resistant CoatingNegotiableMOQ: 1 Square Meter

-

The Surface Repair of Stainless Steel Plates by the Manufacturer Adopts Arc Spraying Process LX88A Coating, Which is Super Hard and Wear-resistantNegotiableMOQ: 1 Square Meter