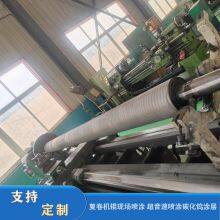

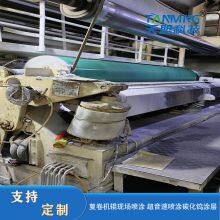

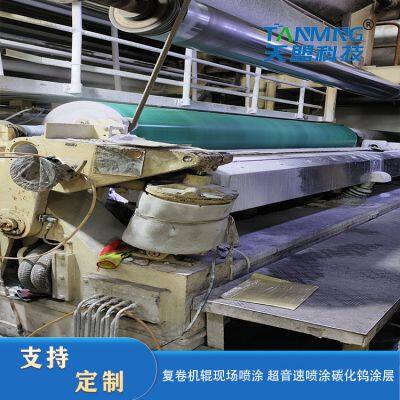

In modern industrial production, the rewinding machine, as one of the important equipment, the performance of its bottom roller directly affects the production efficiency and product quality. To enhance the durability and corrosion resistance of the bottom rollers, an increasing number of enterprises have begun to adopt supersonic spraying technology, especially the application of tungsten carbide coatings, which has become an important technological innovation in the industry.

Supersonic spraying is an advanced coating technology that forms a high-density and high-adhesion coating by spraying paint onto the surface of a substrate at supersonic speed. This technology not only enhances the compactness of the coating, but also significantly improves its wear resistance and corrosion resistance. Tungsten carbide, as an excellent wear-resistant material, when applied to the bottom rollers of the rewinding machine, can effectively extend the service life of the equipment and reduce maintenance costs.

In the practical application of the bottom roller of the rewinding machine, the surface of the bottom roller is often affected by multiple factors such as friction, impact and corrosion. Traditional coating techniques often fail to meet the requirements of high strength and high wear resistance. By applying a supersonic tungsten carbide strengthening coating to the bottom roller on site, not only can the surface hardness of the bottom roller be enhanced, but also an effective protective barrier can be formed to resist the erosion of the external environment.

The advantages of anti-corrosion and wear-resistant coatings

1. Wear resistance: The tungsten carbide coating has a very high hardness and can effectively resist wear. Especially in high-load and high-speed working environments, it can significantly reduce the wear rate of the bottom roller.

2. Corrosion resistance: This coating can effectively prevent chemical substances and moisture from eroding the bottom roller, extend the service life of the equipment, and reduce downtime and maintenance costs caused by corrosion.

3. Strong adhesion: The supersonic spraying technology can ensure a good adhesion between the coating and the base material of the bottom roller, avoiding the phenomenon of coating peeling or detachment.

4. Convenient on-site construction: Compared with traditional coating techniques, supersonic spraying can be carried out on-site, reducing the disassembly and transportation of equipment and improving construction efficiency.

The supersonic spraying of tungsten carbide reinforced coating on the surface of the bottom roller of the rewinding machine is a significant technological innovation. It not only enhances the wear resistance and corrosion resistance of the bottom roller, but also saves a large amount of maintenance costs for enterprises. With the continuous advancement of industrial technology, supersonic spraying technology will be applied in more fields, providing a strong guarantee for the long-term stable operation of equipment.

Send Inquiry to This Supplier

You May Also Like

-

Repair of the Surface of the Drying Cylinder by Spraying Tungsten Carbide+Teflon Anti-corrosion and Wear-resistant Non Stick CoatingNegotiableMOQ: 1 Square Meter

-

Surface Repair of the Mechanical Industry, Multi Section Roller, Supersonic Spraying Processing, Tungsten Carbide Coating, Wear-resistant and Anti-corrosionNegotiableMOQ: 1 Square Meter

-

Boiler Surface Repair and Spraying of Nano Ceramic Coating for Anti-corrosion and Wear PreventionNegotiableMOQ: 1 Square Meter

-

Support Customized Mechanical Sliding Rails for Laser Melting Surface Repair, Anti-corrosion and Wear-resistantNegotiableMOQ: 1 Square Meter

-

Ceramic Coating Scraper, Coating Scraper, Paper Coating Roller and Other Mechanical Scraper ProductsNegotiableMOQ: 1 Square Meter

-

Surface Repair and Aluminum Spraying Treatment Process for Mechanical Valves in the Source FactoryNegotiableMOQ: 1 Square Meter

-

Roller Surface Repair Using Spray Welding Process NI60 Coating Wear-resistant and Anti-corrosion PreparationNegotiableMOQ: 1 Square Meter

-

Mechanical Industry Supersonic Spray Machining Spiral Shaft Surface Repair, Spraying Anti-corrosion and Wear-resistant CoatingNegotiableMOQ: 1 Square Meter

-

The Surface Repair of Stainless Steel Plates by the Manufacturer Adopts Arc Spraying Process LX88A Coating, Which is Super Hard and Wear-resistantNegotiableMOQ: 1 Square Meter

-

Surface Repair of Stainless Steel Plates in the Mechanical Industry, Arc Spraying, Wear Resistance and Corrosion ResistanceNegotiableMOQ: 1 Square Meter