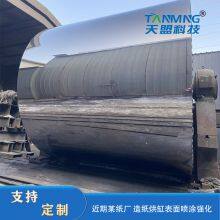

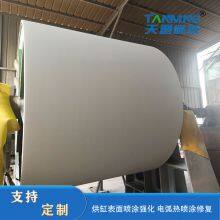

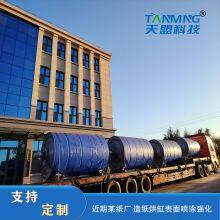

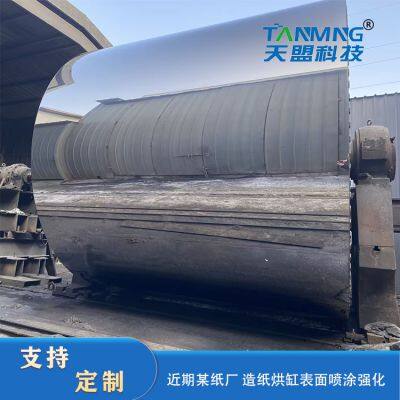

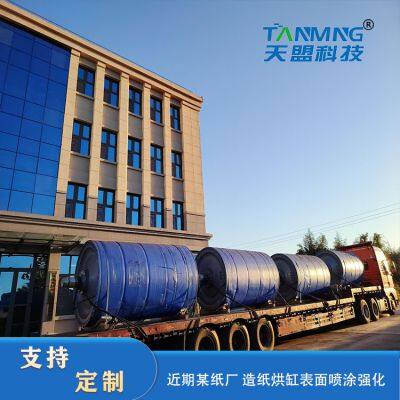

In the paper industry, drying drum is one of the key equipment, its performance directly affects the quality and production efficiency of paper. However, over time, the drying drum can be damaged due to wear, corrosion and other reasons, resulting in production disruption and economic losses. In response to this problem, Jinan thermal spraying technology came into being, especially supersonic spraying technology, has become an ideal choice to improve the dry cylinder.

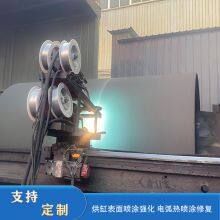

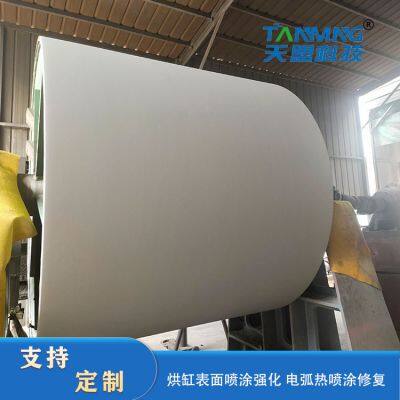

Supersonic spraying technology adopts high speed spraying to evenly coat wear-resistant materials such as tungsten carbide on the surface of the drying roller. This coating not only has excellent wear resistance, but also has good corrosion resistance, which can effectively extend the service life of the equipment. Compared with traditional repair methods, supersonic spraying has higher adhesion and better coating densification, and can better resist harsh working environments.

In addition, Jinan Tianmeng drying roller reduces downtime and improves production efficiency.

Send Inquiry to This Supplier

You May Also Like

-

Preparation of Anti-corrosion And Wear-resistant Spray Welding RollersUS$ 50MOQ: 1 Square Meter

-

Papermaking Drying CylinderUS$ 50MOQ: 1 Square Meter

-

Papermaking Drying Cylinder Accessories And Papermaking Scraper Are Available in Various ModelsUS$ 220MOQ: 1 Metric Ton

-

Jinan Thermal Spraying Plasma Processing of Silicon Carbide CoatingNegotiableMOQ: 1000 Square Meters

-

Surface Repair of the Rewinding Machine RollerUS$ 50MOQ: 1 Square Meter

-

Machine Industry Fluidized Bed Thermal Spraying Processing Teflon Preparation Anti-corrosion Wear-resistant Can Support CustomizedNegotiableMOQ: 1 Square Meter

-

Surface Treatment of Filter Core Plate Using Plasma Technology for Corrosion Prevention, Wear Resistance, and High Temperature ResistanceNegotiableMOQ: 1 Square Meter

-

Surface Treatment of Machinery Industry Thermal Spraying Plasma Process Anti-corrosion, Wear-resistant and Thermal InsulationUS$ 268 - 468MOQ: 1 Square Meter

-

Surface Treatment in the Mechanical Industry, Spraying Tungsten Carbide for Corrosion Prevention and Wear ResistanceNegotiableMOQ: 1 Square Meter

-

Directly Supplied by the Manufacturer for Laser Cladding Surface Treatment, Piston Rod Surface Repair, Anti-corrosion and Wear-resistantNegotiableMOQ: 1 Square Meter