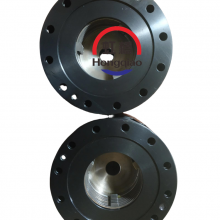

Working Principle:

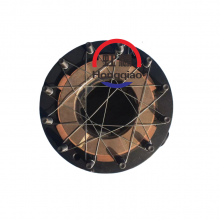

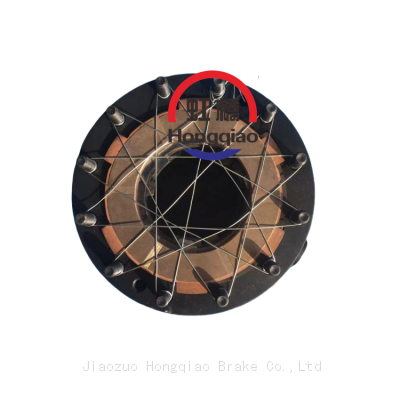

The YZQ series hydraulic disc brake is a safety anti-skid device for coal mining machines. It is located at the end of the shearer's traction motor, The brake housing is fixed to the traction unit housing by connecting bolts, the dynamic friction plate is sleeved on the spline groove of the coal mining machine brake shaft, and the static friction plate is sleeved in the brake housing through the spline. The factory state of the brake is that the spline teeth of the dynamic friction plate are in the same direction (the same phase difference). Do not manually release the spring pressure before installation to avoid phase disorder of the dynamic friction plate.

Performance parameter

Model | Working medium | Opening pressure (Mpa) | Rated speed (rpm) | Braking torque (Nm) | Dimensions | ||

Static moment | Dynamic torque | B | L | ||||

YZQ-390 | 1.8 | 1470 | ≥390 | ≥300 | ∮155

| 91 | |

YZQ-550 | ≥550 | ≥470 | ∮155

| 95 | |||

YZQ-700 | ≥700 | ≥600 | 200 | 122 | |||

YZQ-700B | ≥700 | ≥600 | ∮155

| 105 | |||

YZQ-1000D | ≥1500 | ≥1100 | 285 | 132 | |||

N45-XM-A | ≥1200 | ≥780 | ∮256 | 134 | |||

Use

When the coal mining machine is moving, the brake is supplied with oil by the oil circuit controlled by the height adjustment system, and the minimum release pressure of the hydraulic system is 1.8MPa. The hydraulic oil enters the cylinder through the oil inlet hole, and the piston compresses the disc spring under the action of the hydraulic pressure, the dynamic and static friction plates are separated, and the brake is released; when the coal mining machine stops, the control oil circuit is cut off, the system pressure is zero, and under the action of the brake disc spring force, the disc spring compresses the dynamic and static friction plates with the help of the piston, generating a friction torque, the brake is in a braking state, and the coal mining machine is braked.

If the hydraulic system fails or is overhauled, the hydraulic brake is released manually by mechanical means: that is, remove the two screw plugs on the rear end cover, connect the release bolt originally fixed on the rear end cover or the front end cover to the threaded hole on the piston through the threaded port on the rear end cover and tighten it, compress the disc spring through the piston, separate the friction plates, and release the brake. After use, please tighten the release bolt on the front end cover (tighten it) for next use.

Send Inquiry to This Supplier

You May Also Like

-

Hydraulic Active Rotor BrakeNegotiableMOQ: 1 Piece

-

SBD-C Series Safety BrakeNegotiableMOQ: 1 Piece

-

SBD-C Series Disc BrakeNegotiableMOQ: 1 Piece

-

SBD-D Series Safety Disc BrakeNegotiableMOQ: 1 Piece

-

SBD-D Series Emergency Disc BrakeNegotiableMOQ: 1 Piece

-

SBD-A Series Emergency Disc BrakeNegotiableMOQ: 1 Piece

-

SBD-A Series Safety Lifting Disc BrakeNegotiableMOQ: 1 Piece

-

YPYD-500 Electro Hydraulic Safety Disc BrakeNegotiableMOQ: 1 Piece

-

SB Series Electro Hydraulic Safety Disc BrakeNegotiableMOQ: 1 Piece

-

Electro Hydraulic Safety Disc BrakeNegotiableMOQ: 1 Piece