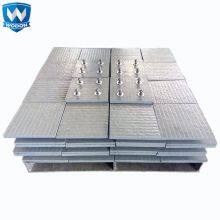

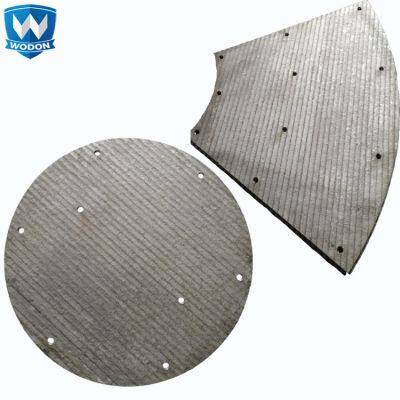

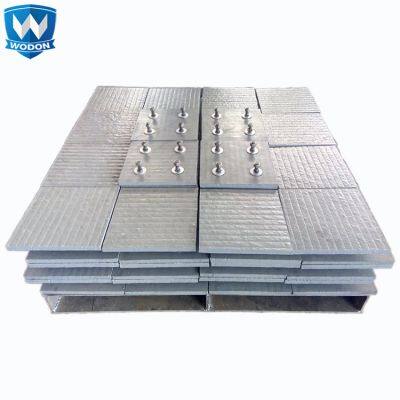

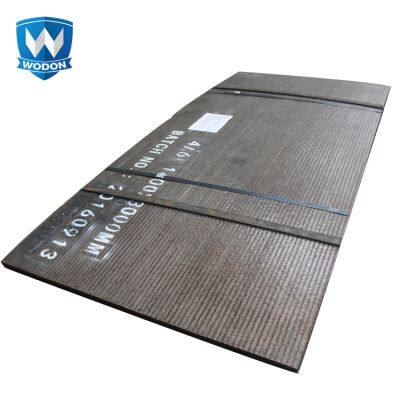

Mixed Concrete Batching Plant and Mixer Wearing Plate Liners for Mining Machine Parts

mixed concrete batching plant and mixer wearing plate liners for mining machine parts

Production Process

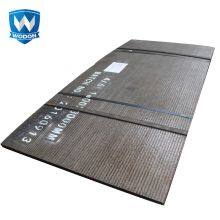

Welding process is the use of the most advanced open arc welding welding process, the various effects of this process on the performance of a very small base , and wear to maximize play. Composite wear plate is ordinary steel (Q235 (A3) or heat-resistant steel (15CrMo, 12Cr! MoV , etc. ) , stainless steel plate formed on the entire volume fraction of more than 50% Cr7C3 carbide -based wear layer , which with high wear resistance , impact resistance, deformable and welding performance, like steel , like direct texturing , cutting and drilling and other processing sectors , processed into mining engineering components to meet the wear and put into use . wear-resistant material with many compared wear-resistant composite plate has its irreplaceable notable features.

Our company has a professional after-sales service team, with many years of experience not only on hardfacing products and applications, but also on the operation of application equipment. We are able to quickly solve customer's problems. If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

Good quality and flatness is our first sight. After discussing on their booth, our team think we find a better producer with very good and competitive price and quality. One more important thing is their professional, skilled and young technican team.

The Wodon abrasion and impact wear plate samples consisted of a high chromium white iron deposit on a steel substrate. The hard facing microstructure contained typically a high volume percent of primary carbides. The primary carbide sizes were typically less than 25μm in diameter, which was considered good for hard facings of these types.

Q: Are you trading company or manufacturer ?

A: We are ISO certified flux cored welding wire and CCO wear plate factory.

Q: Are you able to produce customized chemical composition and dimension?

A: Yes, we could offer special welding wire and wear plate according customers' requirement.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-45 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 20~30% T/T in advance, balance against the copy of BOL. Other payment terms are negotiable.

Q: Do you provide after-sales service ?

A: Our company has a professional after-sales service team, with many years of experience not only on hardfacing products and applications, but also on the operation of application equipment. We are able to quickly solve customer's problems. If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

If our product meets your interest, please feel free to contact us as follow:

Send Inquiry to This Supplier

You May Also Like

-

WODON Manufactured Premium Wear Resistant Liner for Shield MachineCHF 300 - 300MOQ: 1 Square Meter

-

Wodon Chromium Carbide Coated Bin Liner Plate With Super Wear ResistanceCHF 300 - 300MOQ: 1 Square Meter

-

Mining Service High Wear Resistant Abrasion Steel Plate Vibrating ScreenUS$ 60 - 60MOQ: 1 Piece

-

High Chromium Carbide Overlay High Tensile Wear Plate for Excavator Buckets LinerUS$ 1100 - 1100MOQ: 1 Set

-

Wodon Abrasion Resistant Bimetal Liner for Truck Bed Hopper and ChuteCHF 300 - 300MOQ: 1 Square Meter

-

CCO Leader Bucket Wear Liners Mining ProductsCHF 1599 - 1599MOQ: 1 Piece

-

High Chromium Impact Resistant Steel Bimetal Plate for Coal Chute LinerCHF 199 - 199MOQ: 1 Square Meter

-

Anti-abrasion Cladding Lining Plate Hardfacing Wear Plate for Dragline Grab BucketUS$ 120 - 120MOQ: 1 Square Meter

-

Chromium Wear Resistant Ore Mill Feeder Conveyor Wear Liners Steel or Iron Plates Ss400US$ 250 - 250MOQ: 1 Square Meter

-

Wodon Wear Resistant CCO Bimetal Liner for Loading MachineryCHF 300 - 300MOQ: 1 Square Meter