China Supplier's Q345B Steel Coil High Chrome Carbide Hardfacing Plate Compound Base Plate ANSI Cutting Bending Welding

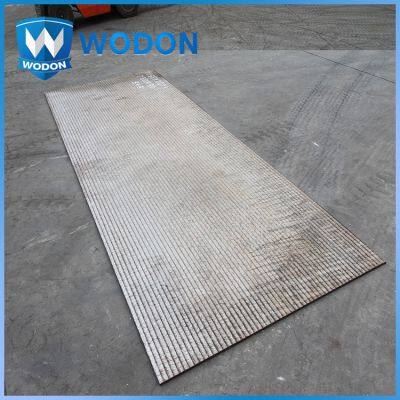

Wodon wear plates are used to make many complex super alloy wear liners to be positioned in high wear places.

We have several equipment to transform our plates: six sets of plasma cutting machine , 4 bending machines and pressing machines, with high processing capacity operated by engineers and technical experts.

We can provide wear plate cutting, bending, bolting, punching and welding according to customer's drawings.

1.Drilling Holes

Straight holes and Countersunk holes.

2.Bolt embedded welding in the back

Embedding the Pre-processed bolt in the back of wear plate.

3.Bending

Wodon wear plate can be cold formed and made into curve or cone.

4.Welding

Wodon wear plate can be welded and assembled into kinds of wear parts.

China supplier Q345B base plate high chrome carbide sheets compound hardfacing plate

Production Specification

Product Name | China supplier Q345B base plate high chrome carbide sheets compound hardfacing plate |

Brand | WODON |

Base Plate | Q235/Q345 |

Hardness | HRC58-65 |

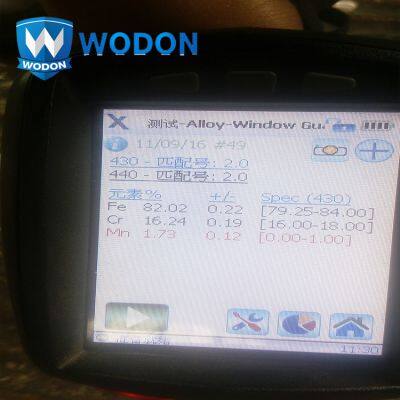

Chemical Composition | C(%): 3.0-5.0 Cr(%): 25-40 |

Hardfacing layer | High chromium high carbide overlay |

Surface Treatment | Hardfacing, clading, coated |

Technique | Hardfacing, open arc welding, submerged arc welding |

Wear Resistance | High wear resistance |

Thickness | 3+3,4+4,5+5,6+4,6+5,6+6,8+4, etc. Customer ' s requirement |

Application | Mining, Steel, Cement, Power, Port, etc. |

Place of Origin | China |

WD wear resistant coal sieve plate components

WD abrasion resistant liners parts

WD complex wear liners parts

WD whirlwind type separator blade with wear plate

Rolling mill slading liner housing liner

WD connecting square pipe and round pipe wear parts

Pre-Sales Service

* Inquiry and consulting support

* Free Samples

* View our factory

After-Sales Service

If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

Wear liners Packing | ||||||

Packaging Details | Steel pallet, Non fumigation pallets , Customized. | |||||

Size | Custimized. | |||||

Delivery Detail | Generally15-20 days, it is according to quantity. | |||||

We use customized size steel pallet to support our wear plate , wear parts and we can also make special customized steel pallet according to the customer's drawing. So that not only support our wear plate and wear parts safely but also easy to transport with.

Why Choose Us

Welcome

Jiangsu Wodon Wear Resistant Material Co.,Ltd(CHINA WODON), located in the northern international shipping center TIANJIN. The company possesses many experienced senior engineers who provides professional solutions in high wear and abrasion resistant applications.

Our products have been widely applied to electric power, cement, mining, iron and steel etc. And with our product can increase the using life 3-4 times, reduce the cost of maintenance and save downtime. As well as the company have passed IOS9001, SGS, IAF.

The products are exported to South Korea, Mongolia, Peru, Australia etc.

We use our own developed CNC automatic welding machine with multi welding guns to weld our own hardface wear plate. It is equipped with four welding guns that can work simultaneously to overcome low productivity, poor flatness and overlay falling off, easily caused by single gun.

This is a high automation level machine. Each welding gun can operate independently and restart exactly from the point it had stopped, Simplifying the operation process. Wear plate manufactured by this equipment have many advantages like flat surface, micro and irregular cracks, and uniform hardness being very well accepted by our customers.

And the most advantange is cost saving, so our customer could get good quality and high cost performance wear resistant plate.

Exhibition in Australia

WODON can offer professional solustions for the abrasion in different working conditions in order to reduce costs, increse lifetime of the workpiece and extend equipment' overhaul period with our super alloy wear liners, therefor building a very good reputation among our customers.

Exhibition in America

WODON is committed to providing high-quality wear plate and flux cored welding wires, willing to work with countries to establish long-term working relationship.

—— President Mr. Zhang

Meeting with south korea customer

Wodon's wear plate and flux cored welding wires has a high amount of chromium carbide hard particles on the overlay alloy. And Wodon wear plates are used to make many complex wear components to be positioned in high wear places.

WODON is committed to providing high-quality wear plate, and with good reputation. Many overseas customers willing to work with our company to establish long-term working relationship.

WODON is the leading manufacturer of wear resistant materials in China. In China, many steelworks, cement plants, coal mine plants and so on, buying wear resistant plate, wear resistant flux cored welding wires and wear resistant parts from our company. As well as established a stable relationship of long-term cooperation. Abroad, our products also sold to many countries, "made in China" is not only excellent quality but also high cost performance.

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A:30% T/T in advance ,balance against copy of BL.

If you have another question, pls feel free to contact us as below:

Send Inquiry to This Supplier

You May Also Like

-

Wodon Excavator Bucket Part Fabricated Wear Plate for MiningUS$ 499.9 - 499.9MOQ: 1 Piece

-

Alloy Abrasion-Resistant Steel Plates ASI Standard Components for Mine Screen Customized Cutting Bending Welding ServicesUS$ 299.59 - 299.59MOQ: 1 Square Meter

-

High Abrasion Hardfacing Wearing Plate Alloy Chute and Hopper Liners Mine ScreenUS$ 399.69 - 399.69MOQ: 1 Square Meter

-

Wodon Excavator Wear Liners Wearable Hardfacing Plate Bucket Steel Product Wearable Hardfacing Plate Bucket Steel ProductUS$ 299.69 - 299.69MOQ: 1 Square Meter

-

Vibrating Screen Chrome Carbide Wear Resistant Sieve Mining PlatesUS$ 499.9 - 499.9MOQ: 1 Square Meter

-

Ming Chrome Carbide Hardfacing Abrasion Vibrating Wear Resistant Sieve PlatesUS$ 399.69 - 399.69MOQ: 1 Square Meter

-

Wodon Wear Resistant Chromium Carbide Steel Plate Durable Concrete Mixer Plate ANSI Certified ASTM Cutting Bending WeldingCHF 300 - 300MOQ: 1 Square Meter

-

Wodon Chromium Alloy Bimetal Hardfacing Plate for Mining MachineryCHF 300 - 300MOQ: 1 Square Meter

-

ASTM G65 Wear Resistant Liner Bimetal Alloy Steel Overlay PlateUS$ 299.69 - 299.69MOQ: 1 Square Meter

-

Wear Resistant Overlay Plate Bimetal Clad Liner Plate Wear Pads for Blast Furnace Inner Wall Anti-wearUS$ 120 - 120MOQ: 1 Square Meter