High Abrasion Hardfacing Wearing Chromium Alloy Suppliers Excavator Bucket Steel Plate

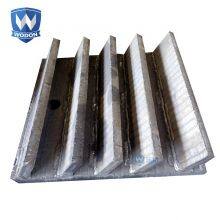

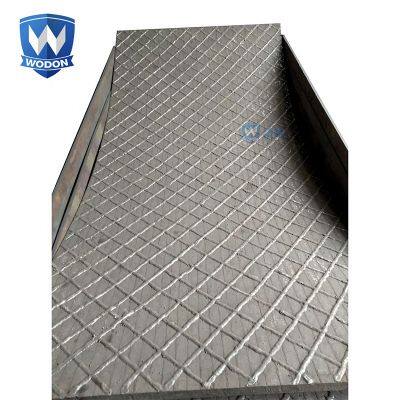

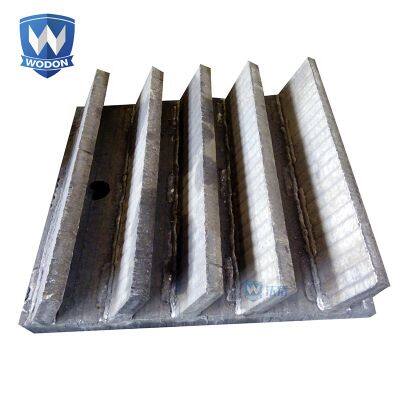

Wodon wear plates are manufactured by welding one or multiple wear resistant layers on a medium or low carbon steel base plate.The overlay alloy has a high amount of chromium carbide hard particles which makes the plate have good wear and impact resistance.

Overlay thickness range: 3-50mm

Wear plate size(mm): 1400*3000, 1400*3400, 1400*3500,

1500*3000,2000*3000, 2100*3500,

others on request

Chromium Carbide Overlay Wear Plates

| Model | Characteristics | Hardness | Chemical Composition (%) | Operating Temperature | ||||||

| (HRC) | C | Cr | Mn | Si | Mo+Nb | Ni+V+W | Fe | |||

| WD-1000 | Common chromium carbide wear plate, suited for use in general wear applications involving low to medium impact | 58-65 | 3.0-5.0 | 17.0-27.0 | 1.0-3.0 | 1.0-3.0 | / | / | Bal. | <400℃ |

| WD-1100 | ||||||||||

| WD-1200 | High chromium carbide wear plates, Cr content is high up to above 40%,suited for use in severe abrasion applications, involving low to medium impact. | 58-65 | 3.0-6.0 | 25.0-45.0 | 1.0-3.0 | 1.0-3.0 | / | / | Bal. | <400℃ |

| WD-1500 | ||||||||||

| WD-1600 | Impact resistant wear plates, Independent R&D, suitable for medium to high impact. | 58-65 | 3.5-6.5 | 25.0-45.0 | 1.0-3.0 | 1.0-3.0 | * | / | Bal. | <600℃ |

| WD-1800 | Heat resistant wear plate, heat resistance maximum up to 900℃ | 58-65 | 4.0-7.0 | 25.0-40.0 | / | / | * | * | Bal. | <900℃ |

| WD-NC100 | Crack free wear plate, mainly used as housing liner and side plate in steel mill | 50-55 | ||||||||

| Other series | Customized on request, special chemical element included for special abrasion fields | / | ||||||||

| Sheet size: 1400*3400mm 1400*3000mm 1500*3000mm 1400*3500mm 2000*3000mm 2100*3500mm Other on request | ||||||||||

| Base metal material: Q235, Q345 and so on. | ||||||||||

| Overlayer thickness: 3-50mm | ||||||||||

Jiangsu Wodon Wear Resistant Material Co., Ltd. (China Wodon) is a manufacturing factory specializing in the development and production of wear resistant materials. We are headquartered in Jiangsu, a port hub city in North China. There are over 300 staffs, including 30 experienced R&D engineers. Our main products include: Chromium carbide overlay (CCO) wear plates, Flux cored hardfacing welding wires etc.

With independent intellectual property rights and a number of patents, we have a strong R&D and debugging team, which can provide customers with a streamlined service.

Since its inception, with the huge investment and independent technology research and innovation, Wodon has been taking the lead in providing premium quality CCO wear plates, hardfacing welding wires as well as excellent repairing technique, all of which win trust and acceptance from our clients worldwide. Meanwhile, the company also employs many experts and professors in the wear resistant industry as the company’s technical consultant to ensure strong technical strength and production capacity, we are dedicated to providing quality and cost-effective wear solutions that completely fulfill the requirements of clients.

4 Major production bases: Jiangsu, Hebei, Hunan, Jiangsu

68 Wear plate production lines (over 130 welding torches)

5 Welding wire production lines

Annual output of chromium carbide wear plates: 200,000 square meters

Annual output of flux cored hardfacing wires: 9000 tons.

High abrasion resistant wear plate for hardfacing continuous casting roller

1. The overlay chemical composition is the key

The main ingredients of Wodon plates are C(%) :3.0-5.0 and Cr(%):25-40. This chemical proportion results in a large amount of Cr7C3 chrome carbide hard particles. The micro-hardness (up to HV1800) of these particles throughout the layer will guarantee a super wear resistant surface.

Performance test:

Test equipment: Quartz sand rubber wheel abrasion test machine.

Conditions: Choosing same dimension specimens for different materials and wear plate producers, and put them under the same wearing working conditions in our testing equipment.

45 minutes for each specimen

Results: The test results show that the life span of Wodon wear plate is 2.5 times higher than domestic wear plates and 1.5 times than imported ones.

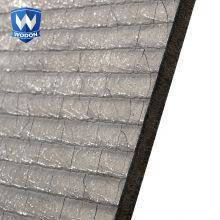

2. Chromium carbide microstructure

The wear resistance of wear plate depends mostly on the hardness, shape, size, amount and distribution of the chromium carbide hard particles.

As you can check on the picture, the carbide (Cr7C3) volume fraction on the microstructure is above 50%.

3. Bonding strength between the overlay and base plate.

The overlay and base plate are very well bonding. The overlay will penetrate into base plate about 0.8mm-1.8mm, reaching up to 350Mpa in our tests.

ASTM G65 High abrasion resistant wear plates for coal chemical industry

Quality Assurance

Wodon has professional technicians and excellent engineers to make product quality improve constantly. Since its foundation Wodon follows the way of professional development and wins the market with its advanced technology development, perfect product quality and fully integrated services. We have kept long closed cooperation relations with Beijing Industry University and scientific research institutions like Steel Research headquarters and Beijing Electricity Research .

Quality Guarantee

Wodon has ISO quality management system certification and execute all the contents of certification. We set up strict rules and regulations, process, and make specific requirements on each quality management from Inspection of raw materials into factory, product realization process, process inspection , final inspection, product protection, Incoming product management until final after - sales service.

Commitment

Wodon has specialized after-sales team-work, can solve problems efficiently and quickly. If any problems, related persons will solve it within 12 hrs after getting notice from suppliers.

Send Inquiry to This Supplier

You May Also Like

-

Ming Chrome Carbide Hardfacing Abrasion Vibrating Wear Resistant Sieve PlatesUS$ 399.69 - 399.69MOQ: 1 Square Meter

-

Wodon Wear Resistant Chromium Carbide Steel Plate Durable Concrete Mixer Plate ANSI Certified ASTM Cutting Bending WeldingUS$ 300 - 300MOQ: 1 Square Meter

-

Wodon Chromium Alloy Bimetal Hardfacing Plate for Mining MachineryUS$ 300 - 300MOQ: 1 Square Meter

-

ASTM G65 Wear Resistant Liner Bimetal Alloy Steel Overlay PlateUS$ 299.69 - 299.69MOQ: 1 Square Meter

-

Wear Resistant Overlay Plate Bimetal Clad Liner Plate Wear Pads for Blast Furnace Inner Wall Anti-wearUS$ 120 - 120MOQ: 1 Square Meter

-

Hardfacing Bimetal Steel Plate Wear Resistant PlateUS$ 299.59 - 299.59MOQ: 1 Square Meter

-

Wodon Chromium Carbide Wear-resistant Parts for Steel Mill SliderUS$ 300 - 300MOQ: 1 Square Meter

-

Wodon Cco Plate for Crusher Chute Feeder Tunnel Boring Machine Truck Bed Hopper LinerUS$ 100 - 100MOQ: 1 Square Meter

-

Wodon Chromium Carbide Hardened Wear Components With Super Wear ResistanceUS$ 300 - 300MOQ: 1 Square Meter

-

Wodon Abrasion Resistant Bimetal Liner for Bucket and ChuteUS$ 300 - 300MOQ: 1 Square Meter