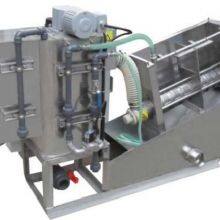

Stacked Sludge Dewatering

Product Structure

The main part of the dehydrator is a filter device

that a screw runs through the stacked fixed rings

and moving ring

The small gaps between fixed rings and moving

ring can filter the sludge,and the lumen between

screw and rings is filled with polymer grains.The

moving ring transfers the sludge to the end of the

machine with pressure and extruds sludge cakes.

The running of the screw drives the moving ring

to clean the gaps and avoid jam.

Product Application:City mixed raw sewage、Food &beverage industry、Chemical industry、Stone &mine sewage、Leather &tannery sewage、Paper&pulp sewage、Elecro-plating sewage、Pringting &dyeing sewage、Power plant、Petrochemical industry

Product Features

1.Suitable for sludge treatment of high/low consistency.

2.There is no need to worry about jam up.Reduce the cleaning water consumption.

3.The electrical cabinet,disposal tank and dehydrator are integrated, reducing the covering area and brings convenience to installment.

4.The dehydrator is enclosed working,reducing the bad smell and improving the working environment.

5.Automatically working for 24 hours,reducing the labor strength of workers

6.The slow running speed of screw shaft reduces the power consumption and noise.

7.It is made with stainless,extending the service life.

8.It is convenient for daily maintenance.

Product Parameters | |

Treating Capacity | 3~300(DS-kg/h) |

Power Consumption | 0.2~6.0kw/h |

Cleaning Water Consumption | 24~216L/h |

Macromolecule Polymer Addition Rate | 2.0~4.0(kg/Ton D.S) |

Water Pressure | 0.2~0.3MPa |

Distance of Outlet Exit to Gound | 215~500mm |

Replacement Period of Screw Axis | 3~11 year |

Replacement Period of Moving Ring | 1~4 yea |

Send Inquiry to This Supplier

You May Also Like

-

Vertical Stationary TMR Mixer WagonNegotiableMOQ: 1 Set

-

Portable Concrete MixerNegotiableMOQ: 2 Sets

-

Rotary Drum Thickening/Dehydrating Belt PressesNegotiableMOQ: 1 Set

-

Carbon Fiber Used for the Sewage and Water TreatmentNegotiableMOQ: 10 Kilograms

-

Carbon Fiber Used for the Sewage and Water TreatmentNegotiableMOQ: 10 Kilograms

-

Multi-work Snow Clearing RobotNegotiableMOQ: 1 Set

-

Printing Booksand Periodicals MagazineNegotiableMOQ: 1 Set

-

Water Bath SterilizerNegotiableMOQ: 1 Set

-

Multi Head Embroidery MachinesNegotiableMOQ: 1 Set

-

Coffee Bean Sorting Machine Grain Gravity Separator Machine Caraway Seed Density SeparatorNegotiableMOQ: 1 Set