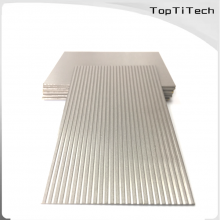

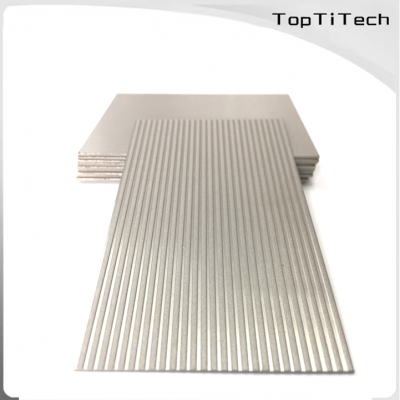

Product Introduction

Titanium metal powder sintered porous fluidized plate is formed by high temperature forming and sintering of metal or alloy powder and has a rigid structure.

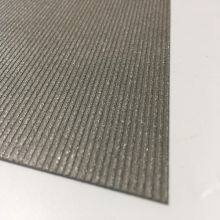

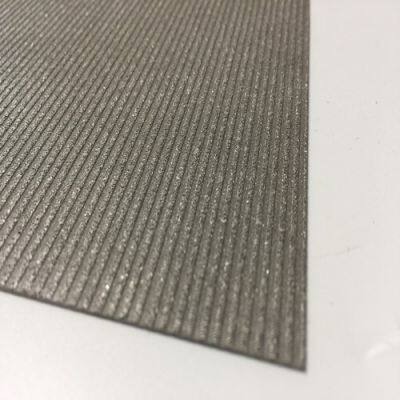

There are a lot of connected or partially connected pores in the substance. Powder particles that are both regular and irregular make up the pore structure. The size and distribution of the pores are related to the size of the particles. The porosity can be adjusted according to the combination of powder particle size and preparation process to meet the actual needs of customers.

Advantages: Good permeability, controllable pore size and porosity, stable shape, high filtration accuracy, wear resistance, good mechanical properties, good thermal conductivity, good heat resistance, heat dissipation, backwashing, and repeated use.

Titanium sintered porous materials are allowed to be used in the following environments: 3% hydrochloric acid, 5% sulfuric acid, nitric acid of various concentrations (fuming nitric acid is prohibited), chlorine water, seawater, the aqueous solution of sodium hydroxide, carbonate, and chloride salt.

Properties of Sintered Porous Titanium Materials

High-temperature resistance, normal use 300 ℃.

Excellent plasticity, high mechanical strength, and machinability.

Corrosion resistance, and anti-oxidation, can be used in nitric acid, sulfuric acid, dilute hydrochloric acid (5%), acetic acid, liquid hydrogen, and liquid nitrogen environment.

Good molding process, one-time molding processing can be carried out according to customer drawings.

High filtration precision, good purification effect.

No particles fall off, the interior structure is steady, and the pores are uniform.

Good air permeability is easy to blowback and clean and can be regenerated online for repeated use.

Wear-resistant and impact-resistant, good mechanical properties

Production steps: powder sieving--molding--vacuum sintering

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the designated place of the customer without damage.

Contact Us

TEL: +8619992203758

FAX: 0917-3873009

Email:karrykang@bjygti.com

Company: TOPTITECH -- BAOJI YINGGAOCO., LTD

Website:/

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Send Inquiry to This Supplier

You May Also Like

-

Titanium Powder Diffuser Aerator for Ozone Hydrogen Oxygen Diffusion Oxygenating Water 100MM,150MMUS$ 3 - 100MOQ: 1 Piece

-

Sintered Porous Titanium Rod Filter Element For FiltrationUS$ 3 - 100MOQ: 1 Piece

-

Sintered Porous Titanium Powder Filter Cartridges for FiltrationUS$ 3 - 100MOQ: 1 Piece

-

10um Sintered Porous Ti Titanium Plate for Gas DiffusionUS$ 3 - 100MOQ: 1 Piece

-

Sintered Titanium Frit for PEM ElectrolyzersUS$ 3 - 100MOQ: 1 Piece

-

Pure Titanium Electrode Porous Fiber Felts For PEM Fuel CellUS$ 5 - 150MOQ: 1 Piece

-

Sintered Nickel Fiber Felt For PEM Electrolyzer GDLUS$ 5 - 150MOQ: 1 Piece

-

Porous Titanium Round Plate Diffusion Layer Hydrogen ElectrodeUS$ 3 - 100MOQ: 1 Piece

-

0.8um Microns Titanium Sintered Porous Metal Filter CartridgeUS$ 3 - 100MOQ: 1 Piece

-

20'' Porous Titanium Rod Filter Water Treatment FilterUS$ 3 - 100MOQ: 1 Piece