1um Titanium Powder Sintered Filter for Acidic Waste Gas Treatment

Product Introduction

During the chloride process for TiO₂ manufacturing, the filter serves as a pre-filter in high-temperature (200–300°C) exhaust trains, removing unreacted TiCl₄ and chlorine particulates before catalytic converters. Mounted in parallel arrays within FRP housings, its sintered matrix withstands the abrasive nature of titanium oxychloride dust while maintaining <50Pa pressure drop across continuous 24/7 operation cycles.

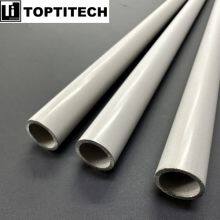

TOPTITECH's 1um Titanium Powder Sintered Filter for Acidic Waste Gas Treatment utilizes grade-1 titanium powder sintered under controlled atmosphere to achieve 1μm absolute filtration efficiency. The monolithic structure with 30-40% porosity ensures optimal gas permeability while maintaining mechanical integrity under acidic exhaust conditions. The M30 threaded interface provides leak-proof connection compatibility with standard industrial gas handling systems, and the 500mm×80mm cylindrical design maximizes filtration surface area within compact installation footprints.

The sintered titanium matrix exhibits exceptional corrosion resistance to sulfuric, hydrochloric, and nitric acid vapors, with inherent thermal stability up to 280°C. Uniform pore distribution enables consistent particulate capture without premature clogging, making it ideal for continuous operation in chemical processing, semiconductor manufacturing, and metallurgical exhaust treatment applications. The absence of binders or secondary coatings eliminates potential degradation points in aggressive environments.

Specifications

Material: GR1 Titanium powder

Pore size: 1um

Diameter: 80mm

Length: 500mm

Porosity: 30%-40%

Technique: Sintering

Features

Superior Acid Resistance

The 1um Titanium Powder Sintered Filter demonstrates unmatched corrosion resistance in acidic environments due to its pure titanium composition and binder-free sintering process. Its homogeneous microstructure withstands prolonged exposure to sulfuric, hydrochloric, and nitric acid vapors without structural degradation, outperforming polymer-based or coated metal alternatives in aggressive waste gas streams.

Precision Filtration Performance

With 1μm absolute filtration accuracy achieved through controlled particle size distribution and optimized sintering parameters, this filter ensures consistent particulate removal efficiency. The uniform pore geometry minimizes pressure drop while maintaining high dust-holding capacity, critical for industrial applications requiring stable filtration performance over extended operational cycles.

Thermal and Mechanical Stability

The monolithic titanium matrix retains dimensional integrity under thermal cycling up to 280°C, eliminating risks of delamination or cracking common in composite filters. Its isotropic strength distribution accommodates vibrational stresses in exhaust systems, with the M30 threaded interface providing robust mechanical sealing under fluctuating pressure conditions.

Sustainable Operational Economics

The absence of consumable components and non-degrading titanium material reduces lifecycle maintenance costs. Regenerative cleaning methods such as ultrasonic or backflushing restore filtration efficiency without damaging the sintered structure, enabling repeated use in batch processing applications.

Seamless System Integration

Standardized M30 threading ensures compatibility with existing ductwork and monitoring equipment, reducing retrofit downtime. The filter's axial symmetry facilitates installation in multi-stage filtration arrays, while its compact footprint optimizes space utilization in modular gas treatment units.

Material Purity Assurance

Grade-1 titanium feedstock guarantees negligible metallic contamination in filtered gas streams, meeting stringent requirements for semiconductor fabrication and pharmaceutical exhaust treatment. The sintered pore network inherently resists bacterial colonization, preventing secondary contamination in sensitive industrial processes.

Application in Acidic Waste Gas Treatment

Semiconductor Lithography Exhaust Systems

The 1um Titanium Powder Sintered Filter is deployed downstream of immersion lithography tools to capture hydrofluoric acid (HF) and nitric acid (HNO₃) vapors generated during photoresist stripping. Installed in vertical exhaust stacks with M30 flange connections, it intercepts submicron acid droplets and silicon-containing particulates before gas enters centralized scrubbers.

Electroplating Acid Mist Control

In hard chromium and nickel electroplating lines, the filter integrates into slot-type ventilation hoods above plating tanks to neutralize sulfuric and hydrochloric acid mists. The 500mm cartridge length provides sufficient dwell time for coalescing acid aerosols into larger droplets, which are subsequently drained to wet scrubbers. Its titanium construction resists pitting from chloride-rich environments, outperforming polymer mist eliminators in high-current-density applications.

Titanium Dioxide Production Off-Gas Treatment

During the chloride process for TiO₂ manufacturing, the filter serves as a pre-filter in high-temperature (200–300°C) exhaust trains, removing unreacted TiCl₄ and chlorine particulates before catalytic converters. Mounted in parallel arrays within FRP housings, its sintered matrix withstands the abrasive nature of titanium oxychloride dust while maintaining <50Pa pressure drop across continuous 24/7 operation cycles.

Package and Shipment

1. Sintered Filters are usually packed in cartons, wrapped in soft film, and fixed in a box filled with industrial foam cotton, and the outer baler is packed with plastic bags with no damage during transportation.

2. Wooden box export packaging can also be customized. The foam cotton can be filled and fixed, the external box is sealed, the bottom is specified, the whole packaging is processed, and the goods can be delivered to the customer's designated place without damage.

Contact Us

TEL: +8619992203758

FAX: 0917-3873009

Email:karrykang@bjygti.com

Company: TOPTITECH —— BAOJI YINGGAOCO., LTD

Website:https://www.toptitech.com/

ADD: No. 195, Gaoxin Avenue, High-tech Development Zone, Baoji City, Shaanxi, China

Send Inquiry to This Supplier

You May Also Like

-

Sintered Porous Titanium Plates For MufflersUS$ 3 - 100MOQ: 1 Piece

-

Sintered Porous Titanium Rod Filter CartridgesUS$ 3 - 100MOQ: 1 Piece

-

Titanium Sintered Porous Metal Filter Fluidized PlateUS$ 3 - 100MOQ: 1 Piece

-

Titanium Sintered Corrugated PlateUS$ 3 - 100MOQ: 1 Piece

-

Powder Sintered Filter Elements For FiltrationUS$ 3 - 100MOQ: 1 Piece

-

Sus316L Powder Sintered Filter CartridgeUS$ 3 - 100MOQ: 1 Piece

-

Sintered Metal Filter ScreenUS$ 3 - 100MOQ: 1 Piece

-

Porous Metal Explosion-proof Filter ElementUS$ 3 - 100MOQ: 1 Piece

-

Titanium Powder Diffuser Aerator for Ozone Hydrogen Oxygen Diffusion Oxygenating Water 100MM,150MMUS$ 3 - 100MOQ: 1 Piece

-

Sintered Porous Titanium Rod Filter Element For FiltrationUS$ 3 - 100MOQ: 1 Piece