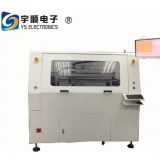

0.4-6.0mm Thickness Automated In-line PCB Routers YSVC-450 For FR4, CEM1, CEM3

In-line Automatic PCB Routers YSVC-450C FEATURES:

• In-Line Automatic PCB Separator can loading, Cutting , unloading automatically, meet the needs of automatic factory.

• It can adjust width and receive PC board automatically. Meanwhile, it can identify the finished PCB board and waste automatically after cutting, save labor costs.

• Equip high-speed CCD with automatic vision alignment system at set, great improve the precision of cutting and operation efficiency.

• Use high-speed main shaft to cut PCB, less cutting stress, high precision, and apply to any form of PCB.

• Dual tables motion could carry out PCB cutting and placing at the same time, improve operation efficiency.

Advantages:

1. Using double slide into place device, reduce the cutting waiting times, increase production capacity. 2. Avoid artificial flap caused by the cracking of tin and part damage and other issues.

3. Avoid using blunt or fold, produced by mechanical stress.

4. Suitable for the finished plate arc and line cutting.

5. Suitable for small pieces of the final cutting, base plate of a mobile phone, PDA, PC interface card and so on.

Operational Vision: • Diagrammatic window operating pages, easy to learn and operate. • Directly edit the cutting programming on screen.

System Setting: • Provides the fine tuning revise by diagrammatic machine. • Set the related parameters of cutting.

Maintenance Program: •Provides the fine tuning revise y diagrammatic machine. •Windows Operational Environment: Easy to learn and operate.

APPLICATION:

•In-line Automatic PCB Separator can loading, cutting, identification, unloading automatically, consistent with operation save labor costs.

•Equip high speed CCD with automatic vision offset at set, especially for high precision and production of PCB cutting process.

•Apply to small connected PCB, such as cell-phone, digital camera, GPS and MODULE, cutting processing.

•Extended size applies to those large PCB of digital TV, PCB mainframe, workstation, and servo cutting process.

•Standard jig or special purpose jig, to aid in PCB cutting to increase production, is optaional. •Placing working pieces on the dual table to less the waiting time and increase the production.

•You can use variety programs for receiving PC board to achieve fully automation, saving labor costs.

SPECIFICATIONS:

Send Inquiry to This Supplier

You May Also Like

-

LED Automatic Rubberizing MachineUS$ 1000 - 4000MOQ: 1 Set

-

0.5~0.8Mpa YSV-4A COB Board PCB DEPANELING MACHINE /pcb DepanelizerUS$ 1000 - 20000MOQ: 1 Set

-

YSV-5A Fully Automatic Double Direction PCB Depaneling MachineUS$ 1000 - 20000MOQ: 1 Set

-

0.8-5mm Imported High Speed Steel Automatic Pcb Depaneling MachineUS$ 1000 - 20000MOQ: 1 Set

-

0.5~3.5mm Table Multi –blades Depaneling MachineUS$ 1000 - 10000MOQ: 1 Set

-

CE Ultrasonic Pcb Cleaning Machine / 32 L Ultrasonic Cleaning DeviceUS$ 1000 - 4000MOQ: 1 Set

-

Auto Desiccator Desiccant Dry Box Industrial Digital Desiccant CabinetsUS$ 300 - 1000MOQ: 1 Set

-

Imported High Quality Steel SKH-9 Three Sets Of Blades Shaft Multi-Blade PCB Depaneling MachineUS$ 1000 - 10000MOQ: 1 Set

-

6000mm/s CCD+MARK Positioning Automatic Laser Marking Machine/laser Depaneling MchineUS$ 1000 - 10000MOQ: 1 Set

-

Hot Air Reflow Oven For PCB Soldering Machine SMT Welding EquipmentUS$ 1000 - 10000MOQ: 1 Set