Home > Products > Insulating Glass Machine > Spacing bar Bending Machine /Double Glazed/Insulating/Insulated Glass Machine/Aluminium Spacer (LW02)

Spacing bar Bending Machine /Double Glazed/Insulating/Insulated Glass Machine/Aluminium Spacer (LW02)

- 60 Set / Sets per Month

- Qingdao port

- T/T Credit Card

You May Like

-

Vacuum glass production line / Vacuum glass making machine (LW02)

-

Insulating Glass Machine/Double Glass Machine/Aluminium Spacer Bending Machine (LW02)

-

Aluminum spacer bending machines / Double glass spacer bar bending machine (LW02)

-

China Window door double glass making machine / Vacuum glass making machine (LW02)

-

Double glass Plant Manufacturer, Double glass plant machine (LW02)

-

Double Glazed Glass Machine / Double Glazed Glass Equipment (LW02)

Product Details

| Brand Name | Better | Model Number | LW02 |

Product Description

Spacing bar Bending Machine /Double Glazed/Insulating/Insulated Glass Machine/Aluminium Spacer (LW02)

Semi-automatic Alu-spacer bending machine for double glass/insulating glass/vacuum glass

Double glass machinery/Insulating glass processing machine/Vacuum glass making machine/Alu-spacer bending machine/Aluminum spacer strip bender machinery/Aluminum groove insulating glass making machine/Alu-slot double glazing glass production line machine/Hollow glass processing machinery

1.Main Function Introduction

1).The startup was controlled by single button, and it is adopted touch screen.

2).The head of the cutter can be adjusted automatically.It can operates without changing the cutter aluminum spacer when the width of the spacer is bigger than 6mm.

3).Fuji servo feeding system with digital control, bending angle. digital control system, siemens control system.

4).To reconnect the ends automatically, and to prevent the ends being clashed intelligently.

5).Judging the processing data intelligently.

6).The remanent can be processed again and no tailings exist.

7).Cutting the feed supply automatically when the processing is done.

8).Counting the output.

9).Remaining dormant state to save energy consumption when there is no processing.

10).Adopting the emergency stop.

11).Adjusting the bending speed automatically.

12).Performing the processing at a high speed, efficiency and continuity.

13).Adopting an automatic storage tank which can feed the material automatically and reconnect the aluminum spacer automatically.

14).Can bend both the arc and shaped aluminum spacers.

15).Manual control to debugging the trial run.

16).The head of the cutters is adjustable and processing data can be figured by customers themselves.

17).Indicating the relevant information when there is no supply, when it is in dormant state, when there is any malfunction, when it is in working state, and even can indicate debugging information for any wrong with the machine.

18).Adopting clock to display the current date and time.

Kindly note:

Before you buy the machine, please make sure then tell me your local power supply,then we can make the right according to your true voltage.

Kindly and friendly inform:

we have skilled engineers with well English ability in this field about 20 years, they can directly to give you any help on machines by calling or by video link or by email in short time, and before our machine reach your workshop, if you need we help you to design a drawing that tell you all machines should how to place in your workshop ,we can help you to give you a drawing to give you suggestion in short minutes; and if you need we suggest you how many Squaremeters workshop is better for you, you can tell us your plan production, then we can tell your how many machines you needs, then tell you how much Squaremeters workshop is better for you.

2.Main Technical Data

model | LW02 |

Power supply | AC220V,50HZ |

Motor | 2.5KW |

Air supply | 0.6MPa |

Aluminum bar size | width:6mm-24mm |

Length:2000-4000mm | |

Aluminum spacer size | min 250*150mm |

max 2500*2500mm | |

Processing speed | <30s/pcs(1000mm*1000mm) |

Date number | set 4 groups of specification*8 kinds of size*9999 piece at the same time |

Figure Dimension | 10500×2100×2200mm |

Total Weight | 1800Kg |

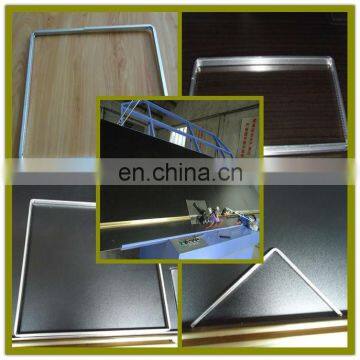

3.More pictures of the model LW02

4.Bended Aluminum spacer sample

5.Full-automatic desiccant filling machine

This machine can togther work with the semi-automatic alu-spacer bending machine.

6.Insulating glass/double glass/hollow glass good advantages

1).sound insulation, noise reduction

2).keep warm

3).dust prevention

4).reduce thermal radiation

7. Contact information

WHY YOU CHOOES US Question AND Answer (If you see same 100% description in other company website on alibab, they copy us, please kindly check and compare.)

1.Question:Are your manufacture?

Answer:we are manufacture of the PVC window door machine, Aluminum window door machines, insulating glass machines.

2.Question:What’s the costomer service ?

Answer:

1).reply within 12 hour

2).deliver max. days within 15 days (If some machines, such as the lock hole milling machine,end milling machine,etc. this is small model, we have in store, and can delivery for you soon within 3-5 days after get your deposit)

3).one to one service

4).24 hours for after -sale serive

5).7 years experience in foreign trade

6).fluent english ,communication barrier free

3.Question:What’s the guarantee ?

Answer:

1).Our guarantee for 1 year.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).one year quality guaranty for the machine (excluding the consumables)

5).We will provide the consumable parts at an agency price

6).24 hours on line service each day, free technical support.

4.Question:if our price is higher than another company or factories ?

Answer:

plaese check, what is is the different of the machine parts ,service and guarantee,especially the machine inner electric parts, sometimes, if machines have breakdown, the most reason is the machine inner electric parts proble, we use the world famous brand parts to install to machines inner, so that can sure you can use the machines very long long years.

belive you will chooes the same value of the machine, not cheaper equipement

5.Question:How long is the delivery time ?

Answer:

For standard machines, it would be 3-15 days; For non-standard machines and customized machines according to clients specific requirements, it would be 15 to 30 days.

6.Question:How's the payment ?

Answer:

Telegraphic Transfer(T/T). or L/C. (If you want by west union, it is also ok.)

Contact Us

- Jinan Amachine Machinery Co., Ltd.

Product Categories

New Products

-

Hollow glass production line machine / Double glass Silicon glue extruder (ST01)

-

Double layer glass making machine / Double glazing glass sealant glue extruder / Hotmelt glue extruder machine (RDJ-B)

-

Hot melt sealant glue extruder of the double glazing glass prodution line / Double glazed glass machinery (RDJ-B)

-

Double glass sealant glue spreading machine / Double glass glue coater (RDJ-B)

-

Semi-automatic glass cutting machine / Semi-automatic cutting glass table / Glass cutting machinery

-

Glass cutting table / Semi-automatic Cutting glass table

-

Glass cutting machine / Cutting glass equipment

-

Glass machinery / Glass processing machinery / Glass product cutting machine

-

Double glass machine / Double glass hotmelt machine (RDJ-B)

-

Double glass machine / Insulating glass machine / Double glazing glass hot melt glue extruder machine (RDJ-B)

-

Double Glass Hotmelt Extruder Machinery (RDJ-B)

-

Hotmelt Extruder Machine for Double Glass Process (RDJ-B)

-

Hotmelt glue extruder insulating glass machine (RDJ-B)

-

hotmelt extruder for making insulated glass/double glass machine/insulating glass machine (RDJ-B)

-

hot melt extruder for insulating glass machinery (RDJ-B)

-

hotmelt extruder for insulating glass (RDJ-B)

-

hotmelt machine extruder for making insulated glass / Hollow glass hotmelt coater machine (RDJ-B)

-

Hot melt machine for insulating glass and double glazing glass / Hot melt glue extruder (RDJ-B)

-

Hot melt extruding machine for insulating glass and double glazing glass production line / Vacuum glass glue extruder (RDJ-B)

-

Hotmelt extruder for making insulated glass / Double glass machine / Insulating glass Equipment (RDJ-B)

-

Hotmelt extruder -Insulating glass hot melt machine- Insulating glass machinery (RDJ-B)

-

Hotmelt machine extruder for making insulated glass / Extruder hotmelt glue machine (RDJ-B)

-

Machine for double glass / Machine for double glass glue coating / Hotmelt glue coater machine (RDJ-B)

-

Hotmelt glue coating machine / Htmelt glue extruder / Double glass machine (RDJ-B)

Popular Searches

Recommended Products

- LIVTER Aluminum profile cutting machineAutomatic feeding cutting machineMetal tube cutting machine

- Custom Aluminum / Magnesium Die Casting Cutting Saw Guard Housings

- CNC drilling machine for upvc window and door making

- Industrial material processing machine CNC machine center

- Industrial material processing machine CNC machine center

- Steel Glass Transportation Racks Slab Buggy Cart

- CNC Aluminium Saw Cutting Machine For Notching

- Notching saw for aluminum curtain wall high precision

- Automatic Water Slot Milling Machine

- Automatic Water Slot Milling Machine

- Aluminum Profile CNC Drilling Milling Machine

- CNC 3+1 Axis Aluminum Profile Drilling and Milling Machine/Aluminum Window CNC Drilling and Milling Machine Aluminum Window Mach

Find Similar Products By Category

- Machinery > Building Material Machinery > Window and Door Making Machine

- Please Enter your Email Address

- Please enter the content for your inquiry.

We will find the most reliable suppliers for you according to your description.

Send Now-

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

sales

Welcome to my shop, I'm glad to serve you. Please feel free to send me any questions you may have.

Your message has exceeded the limit.

- Contact supplier for lowest price

- Customized Request

- Request Sample

- Request Free Catalogs

Your message has exceeded the limit.

-

Purchase Quantity

-

*Sourcing Details

Your inquiry content must be between 10 to 5000 characters.

-

*Email

Please enter Your valid email address.

-

Mobile