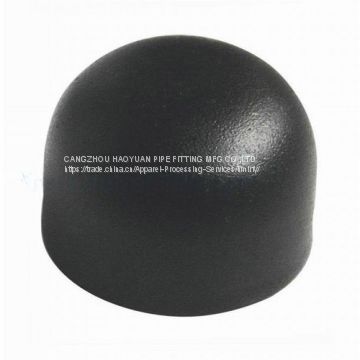

ANSI B16.9 4 Pipe Cap Steel Welded Pipe Fittings groove surface shall not have cracks, delamination, inclusion and other defects. The lower limit of the tensile strength of 540MPa steel plate and Cr-Mo low alloy steel plate by flame cutting the surface of the groove, the application of grinding wheel smooth, and should deal with the surface of the magnetic powder or osmosis test.

ANSI B16.9 caps specifications

High-quality products

Since most of the pipe fittings is for welding, in order to improve the quality of welding, the fittings end are bevelling groove, leaving a certain angle, with a certain edge, which is a relatively strict requirements, how thick edge, and how much deviation angle range has prescribed. Pipe fittings surface quality and mechanical properties and tubes are same. In order to facilitate welding, the connected steel pipe and the fittings materials are the same.

Our packaging

Steel pipe caps production process

Steel pipe caps workshop

Production Process

Send Inquiry to This Supplier

You May Also Like

-

A234 WPB 90 Degree Long Radius ElbowNegotiableMOQ: 1 Bag

-

GOST 17375 Seamless ElbowNegotiableMOQ: 1 Bag

-

ASTM A234 WPB 90 Drees 5D ElbowNegotiableMOQ: 1 Bag

-

S235 Long Radius Butt Welded Pipe ElbowNegotiableMOQ: 1 Bag

-

Carbon Steel 45 Degree Short Radius Butt Weld ElbowNegotiableMOQ: 1 Bag

-

Short Radius Weld ElbowNegotiableMOQ: 1 Bag

-

A234 WPB 45 Degree ElbowNegotiableMOQ: 1 Bag

-

Schedule 80 Short Radius 45 Degree ElbowNegotiableMOQ: 1 Bag

-

ASME Schedule 80 Equal TeeNegotiableMOQ: 1 Bag

-

EN10253 S235 Equal Tee Pipe FittingNegotiableMOQ: 1 Bag