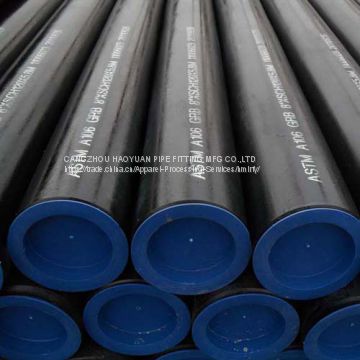

Seamless steel pipe used as a large number of transmission fluid pipelines, such as the transportation of oil, natural gas, gas, water and some solid materials such as pipes. Steel pipe is also widely used in the manufacture of structural parts and mechanical parts, such as oil drill pipe, car drive shaft, bicycle frames and steel construction scaffolding with steel pipe manufacturing ring parts, can improve material utilization, simplify the manufacturing process, saving materials And processing hours, has been widely used to manufacture steel.

Seamless steel pipe wall thickness classification table

| Inch | inch sizc | OD | Wall Thickness Standard | ||||||||||||||

| SCH 5s | SCH 10S | SCH 10 | SCH 20 | SCH 30 | SCH 40 | SCH 60 | SCH 80 | SCH 100 | SCH 120 | SCH 140 | SCH 160 | STD | XS | XXS | |||

| 1/8 | DN6 | 10.3 | - | 1.24 | - | - | - | 1.73 | - | 2.42 | - | - | - | - | 1.73 | 2.41 | - |

| 1/4 | DN8 | 13.7 | - | 1.65 | - | - | - | 2.24 | - | 3.02 | - | - | - | - | 2.24 | 3.02 | - |

| 3/8 | DN10 | 17.1 | - | 1.65 | - | - | - | 2.31 | - | 3.2 | - | - | - | - | 2.31 | 3.20 | - |

| 1/2 | DN15 | 21.3 | 1.65 | 2.11 | - | - | - | 2.77 | - | 3.73 | - | - | - | 4.78 | 2.77 | 3.73 | 7.47 |

| 3/4 | DN20 | 26.7 | 1.65 | 2.11 | - | - | - | 2.87 | - | 3.91 | - | - | - | 5.56 | 2.87 | 3.91 | 7.82 |

| 1 | DN25 | 33.4 | 1.65 | 2.77 | - | - | - | 3.38 | - | 4.55 | - | - | - | 6.35 | 3.38 | 4.55 | 9.09 |

| 1-1/4 | DN32 | 42.2 | 1.65 | 2.77 | - | - | - | 3.56 | - | 4.85 | - | - | - | 6.35 | 3.58 | 4.85 | 9.70 |

| 1-1/2 | DN40 | 48.3 | 1.65 | 2.77 | - | - | - | 3.68 | - | 5.05 | - | - | - | 7.14 | 3.68 | 5.08 | 10.15 |

| 2 | DN50 | 60.3 | 1.65 | 2.77 | - | - | - | 3.91 | - | 5.54 | - | - | - | 8.74 | 3.91 | 5.54 | 11.07 |

| 2-1/2 | DN65 | 73.0 | 2.11 | 3.05 | - | - | - | 5.16 | - | 7.01 | - | - | - | 9.53 | 5.16 | 7.01 | 14.02 |

| 3 | DN80 | 88.9 | 2.11 | 3.05 | - | - | - | 5.49 | - | 7.62 | - | - | - | 11.13 | 5.49 | 7.52 | 15.24 |

| 3-1/2 | DN90 | 101.6 | 2.11 | 3.05 | - | - | - | 5.74 | - | 8.08 | - | - | - | - | 5.74 | 8.08 | - |

| 4 | DN100 | 114.3 | 2.11 | 3.05 | - | - | - | 6.02 | - | 8.58 | - | 11.13 | - | 13.49 | 6.02 | 8.56 | 17.12 |

| 5 | DN125 | 141.3 | 2.77 | 3.4 | - | - | - | 6.55 | - | 9.53 | - | 12.70 | - | 15.88 | 6.55 | 9.53 | 18.05 |

| 6 | DN150 | 168.3 | 2.77 | 3.4 | - | - | - | 7.11 | - | 10.97 | - | 14.27 | - | 18.26 | 7.11 | 10.97 | 21.95 |

| 8 | DN200 | 219.1 | 2.77 | 3.76 | - | 6.35 | 7.04 | 8.18 | 10.31 | 12.70 | 15.09 | 18.26 | 20.62 | 23.01 | 8.18 | 12.70 | 22.23 |

| 10 | DN250 | 273.1 | 3.40 | 4.19 | - | 6.35 | 7.8 | 9.27 | 12.70 | 15.09 | 18.26 | 21.44 | 25.4 | 28.58 | 9.27 | 12.70 | 25.40 |

| 12 | DN300 | 323.9 | 3.96 | 4.57 | - | 6.35 | 8.38 | 10.31 | 14.27 | 17.48 | 21.44 | 25.4 | 28.58 | 33.32 | 9.35 | 12.70 | 25.40 |

| 14 | DN350 | 355.6 | 3.96 | 4.78 | 6.35 | 7.92 | 9.53 | 11.13 | 15.09 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | 9.53 | 12.70 | - |

| 16 | DN400 | 406.4 | 4.19 | 4.78 | 6.35 | 7.92 | 9.53 | 12.70 | 16.66 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | 9.53 | 12.70 | - |

| 18 | DN450 | 457 | 4.19 | 4.78 | 6.35 | 7.92 | 11.13 | 14.27 | 19.05 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | 9.53 | 12.70 | - |

| 20 | DN500 | 508 | 4.78 | 5.54 | 6.35 | 9.53 | 12.70 | 15.09 | 20.62 | 26.19 | 32.54 | 38.1 | 44.45 | 50.01 | 9.53 | 12.70 | - |

| 22 | DN550 | 559 | 4.78 | 5.54 | 6.35 | 9.53 | 12.70 | - | 22.23 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | 9.53 | 12.70 | - |

| 24 | DN600 | 610 | 5.54 | 6.35 | 6.35 | 9.53 | 14.27 | 17.48 | 24.61 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | 9.53 | 12.70 | - |

| 26 | DN650 | 660 | - | - | 7.92 | 12.7 | - | - | - | - | - | - | - | - | 9.53 | 12.70 | - |

| 28 | DN700 | 711 | - | - | 7.92 | 12.7 | 15.88 | - | - | - | - | - | - | - | 9.53 | 12.70 | - |

| 30 | DN750 | 762 | 6.35 | 7.92 | 7.92 | 12.7 | 15.88 | - | - | - | - | - | - | - | 9.53 | 12.70 | - |

| 32 | DN800 | 813 | - | - | 7.92 | 12.7 | 15.88 | 17.48 | - | - | - | - | - | - | 9.53 | 12.70 | - |

| 34 | DN850 | 864 | - | - | 7.92 | 12.7 | 15.88 | 17.48 | - | - | - | - | - | - | 9.53 | 12.70 | - |

| 36 | DN900 | 914 | - | - | 7.92 | 12.7 | 15.88 | 19.05 | - | - | - | - | - | - | 9.53 | 12.70 | - |

| 38 | DN950 | 965 | - | - | - | - | - | - | - | - | - | - | - | - | 9.53 | 12.70 | - |

| 40 | DN1000 | 1015 | - | - | - | - | - | - | - | - | - | - | - | - | 9.53 | 12.70 | - |

| 42 | DN1050 | 1067 | - | - | - | - | - | - | - | - | - | - | - | - | 9.53 | 12.70 | - |

| 44 | DN1100 | 1118 | - | - | - | - | - | - | - | - | - | - | - | - | 9.53 | 12.70 | - |

| 46 | DN1150 | 1188 | - | - | - | - | - | - | - | - | - | - | - | - | 9.53 | 12.70 | - |

| 48 | DN1200 | 1219 | - | - | - | - | - | - | - | - | - | - | - | - | 9.53 | 12.70 | - |

High-quality products

General seamless steel pipe production process can be divided into two kinds of cold drawing and hot-rolled, cold-drawn seamless steel pipe production process is generally more complex than the hot-rolled, the appearance of cold drawn seamless steel pipe is shorter than hot-rolled seamless steel pipe , Cold drawn seamless steel pipe wall thickness is generally smaller than the hot-rolled seamless steel pipe, but the surface looks thicker than seamless steel pipe, the surface is not too rough, caliber is not too much glitch.

Our packaging

Seamless Steel Pipe Production Process

Seamless Steel Pipe workshop

Production Process

Send Inquiry to This Supplier

You May Also Like

-

GOST 17375 Seamless ElbowNegotiableMOQ: 1 Bag

-

ASTM A234 WPB 90 Drees 5D ElbowNegotiableMOQ: 1 Bag

-

S235 Long Radius Butt Welded Pipe ElbowNegotiableMOQ: 1 Bag

-

Carbon Steel 45 Degree Short Radius Butt Weld ElbowNegotiableMOQ: 1 Bag

-

Short Radius Weld ElbowNegotiableMOQ: 1 Bag

-

A234 WPB 45 Degree ElbowNegotiableMOQ: 1 Bag

-

Schedule 80 Short Radius 45 Degree ElbowNegotiableMOQ: 1 Bag

-

ASME Schedule 80 Equal TeeNegotiableMOQ: 1 Bag

-

EN10253 S235 Equal Tee Pipe FittingNegotiableMOQ: 1 Bag

-

A234 WPB Butt Welded Reducing TeeNegotiableMOQ: 1 Bag