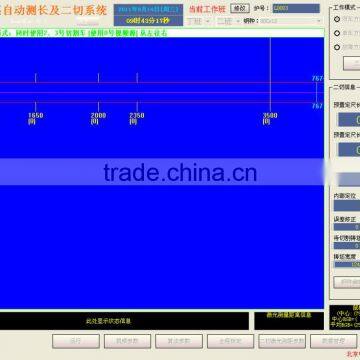

Continuous Casting Billet Optimization of Second Cut to Length Control System

Continuous Casting Billet Optimization of Second Cut to Length Control System

System overview

ZYT billet optimization of the second cut to length control system is suit for a variety of slab thermal (cold) state line measurement / optimization of length.

Measurement:The system can precise measurement for the sheared billet and the result of measurement can be feedback to first cut to length system online automatic tuning.

Optimize the length: Billet can optimized cut secondary for after cutting the double length of the slab, testing blank header real-time location data to the PLC control system roller conveyor roller position to achieve precise control of the slab and match with the fire cutting equipment in order to achieve high-precision second cutting.

Equipment type

ZYT-RQG-IV

System principle

image Collecting and processing. And position calculating for the laser triangulation.

On-site installation of cameras and laser positioning

The horizontal distance from the camera to the slab: 1 ~ 3m

The vertical height from camera to the slab roller: Based on the height of roller 2 ~ 3m

Laser Locator: horizontal distance roller 50 ~ 1000mm, the height based on the roller height.

Laser measurement area: 1 ~ 30m

System parameter

Measurement length range: 2 ~ 18m

Position measurement signal output: 4 ~ 20mA analog output or RS232

Laser accuracy: 2mm ~ 5mm

Data Transfer: Based on TCP / IP protocol standard RJ45 Ethernet

Laser sampling frequency: 1 ~ 2s

Response time: 0.1ms

Network Communication: Ethernet

System composition

² Control cabinet ² Camera ² Image Acquisition ² Image Processing ² Data calculated | ² Laser signal input ² Data Conversion ² Network Reception ² Data output ² Software |

Send Inquiry to This Supplier

You May Also Like

-

Continuous Casting Billet Online Weighing and Cut to Length SystemNegotiableMOQ: 1 Unit

-

1.95*1000*C/S350GD+Z275 Aluminum Zinc Coated Steel PlateNegotiableMOQ: 100 Metric Tons

-

High-temperature Coating Painting MachineNegotiableMOQ: 1 Unit

-

Paint Marking MachineNegotiableMOQ: 1 Unit

-

Billet/Bloom Stamping Type Marking MachineNegotiableMOQ: 1 Unit

-

Continuous Casting Billet Automatic Cut to Length SystemNegotiableMOQ: 1 Unit

-

Square, Round, Rectangle Billet Casting Marking MachineNegotiableMOQ: 1 Unit

-

Continuous Casting Billet Optimization of Second Cut to Length Control SystemNegotiableMOQ: 1 Unit

-

High-Quality Galvanized Steel Coil - Durable & Corrosion-ResistantNegotiableMOQ: 50 Metric Tons

-

Boyuan DX51D+Z80/0.25*1000*C Aluminum Zinc Coated Steel CoilNegotiableMOQ: 100 Metric Tons