High Precision CNC Gear Hobbing Machine (CNC Gear Hobber Machine)

High Precision CNC Gear Hobbing Machine

GHKA-800 GHKC-800 GHKMA-800

Machine Summary

Based on the generating process, the model GHKA-800, GHKC-800, and GHKMA-800 CNC gear hobbing machines are capable of producing cylindrical Spur & helical gears, crowing or slightly tapered gears, involute conical splines, gears with large gelical angle; they also have the function of tooth end rounding, as well as producing wormwheels with automatic radial feed. They are used in the industries, such as engineering machinery, heavy automative, tractor, mining machinery, high speed gearboxes, machine tool & general machinery, etc.

The model GHKC-800 machine is especially used for cutting hardened spur & helical as well as hardened crowing or slightly tapered gears. It can be used for cutting shaping cutter, conical splines and gears with large helical angle.

Performance and Feature

1. The model GHKA-800/GHKC-800/GHKMA-800 machines are of 2-axis CNC one. Their CNC axes includes: X-axis--radial feed, Z-axis--vertical feed, X and Z-axis either work independently, or work coordinately to produce tapered and crowing gears.

2. Various working cycle modes, multi-square and axial working cycle are available.

3. Climb, conventional, climb-conventional and conventional-climb hobbing methods are available.

4. High precision worm gearing are used for the worktable indexing system of the model GHKA-800 to carry out a high indexing accuracy.

5. Our double enveloping worm gearing, which has won the chinese patent, are used for the worktable indexing system of the model GHKC-800. This machine is equipped with a clearance eliminating mechanism.

6. High precision worm gearing are used for the worktable indexing system of the model GHKMA-800 to carry out a high indexing accuracy.

7. Main motor is of AC frequency variable one, and enable a stepless speed control for the spindle.

8. Automatic hob shifting.

9. Separated hydraulic, lubrication and cooling systems.

10. Parameter programming.

11. Standard RS232C interface ensures conveniently calling program from outside computer.

12. Precision ball screws are used for CNC axes. High performance encoders are used for feedback inspecting for the movement of CNC axes to ensure high moving and positioning accuracy of them.

13. Working accuracy of the model GHKA-800/GHKC-800 is up to grade 7.

Technical Parameters

| Specifications | Untis | GHKA-800 GHKC-800 GHKMA-800 |

| Max. workpiece dia. | mm | 800 |

| Max. workpiece module | mm | 10 |

| Max. axial travel | mm | 400 |

| Min. No. of teath on workpiece | 8 | |

| Max. hob dimensions(diameter*length) | mm | 200*200 |

| Hob spindle taper bore | Morse 5# | |

| Max. hobhead swivel angle | deg | ±60 |

| Worktable dia. | mm | 690 |

| Worktable bore dia. | mm | 130 |

| Center distance between hob and worktable | mm | 50-520 |

| Distance between hob axis and worktable surface | mm | 280-680 |

| Distance between tailstock end face and worktable surface | mm | 520-800 |

| Max. hob shifting travel | mm | 90 |

| Hob spindle speed(Stepless) | rpm | 70-300 |

| Max. worktable rotary speed | rpm | 8/8/6 |

| Rapid radial travel | mm/min | 600 |

| Rapid axial travel | mm/min | 600 |

| Coordinate resolution of X and Z-axis | mm | 0.001 |

| Main motor power | kw | 11 |

| Total power | Kva | 32 |

| N.W | kg | 8500 |

| No. of cases | 2 cases in total |

Standard Attachments

- Φ32 and Φ40 hob arbor assemblines

- Φ40 and Φ50 hob arbor assemblies

- Magnetic chip conveyor

- Chip cart

- 8.4" color LCD display

- Workstay

- Fully enclosed guards

- Safety switch

- Hydraulic, lubrication and cooling systems

- Special tools for installation and adjustment

- Change gears

- FANUC 0i CNC system

- Electrical cabinet with air conditioner

- CD with machine data, parameters and programs

- Standard RS232C interface

- 3-color lamp for indicating the status of the machine

- Working lamp

Optional Attachments

- SIEMENS 802D CNC system

- Φ27,Φ32, Φ50 and Φ60 hob arbor assemblies

- Mechanical cutter alignment device

- Oil mist

- Vibration isolating pads

- Workpiece fixtures

Commercial Components

- CNC system: FANUC 0i or SIEMENS 802D

- Imported frequency transformer

- Main hydraulic components: KOMPASS

- Spindle bearings: Japan NSK,etc.

- Hanjiang ball screw

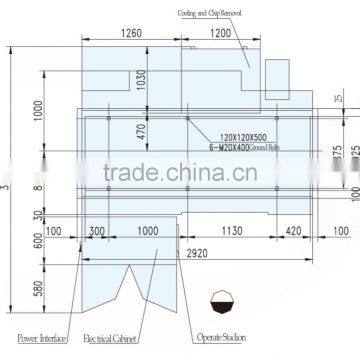

Foundation Plan

Send Inquiry to This Supplier

You May Also Like

-

Acrylic CNC Polishing Machines for Furniture IndustryNegotiableMOQ: 1 Set

-

Reliable Waterjet Cutting Machine for Stone Marble Porcleain Cutting IndustryUS$ 20000 - 40000MOQ: 1 Set

-

Custom Plastic Stainless Steel Aluminum CNC Machining PartNegotiableMOQ: 1

-

CNC Lathe Turned Machining Solid Shaft PinNegotiableMOQ: 1

-

Autopilot Flight Parts Manufacture and MIM Powder MetallurgyNegotiableMOQ: 1 Piece

-

Refrigerant gas R407NegotiableMOQ: 1 Piece

-

High Precision Machining Products of Stainless Steel Made in ChinaUS$ 1.5 - 1.5MOQ: 1000 Kilograms

-

Stainless Steel Welding Tee Pipe FittingsUS$ 0.9 - 0.9MOQ: 200 Pieces

-

OEM CNC Custom Machining Engineering Small Packaging Machine PartsUS$ 0.2 - 100MOQ: 1 Piece

-

Www.xtlaser.comHot Sale Dot Peen Pneumatic Marking MachineUS$ 1,400 - 1,600MOQ: 1 Set