Cost-Effective FIBC Polyethylene Liner, Easy Loading Design, Compatible With Various FIBC Types

As a leading manufacturer based in Xuzhou, Jiangsu, Xuzhou Guozi Intelligent Technology Co., Ltd. specializes in producing high-performance FIBC polyethylene liners that deliver exceptional value. Our cost-effective solutions are engineered to protect bulk materials during storage and transportation while ensuring operational efficiency. The innovative easy-loading design significantly reduces labor costs and minimizes product loss, making it an ideal choice for industries handling powdered and granular substances.

Key Features & Benefits:

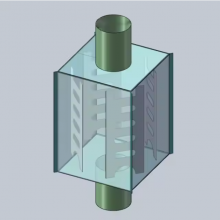

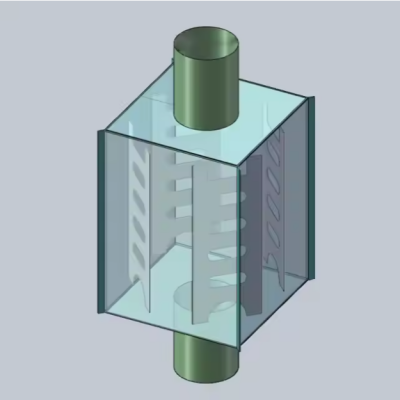

Universal Compatibility – Designed to fit multiple FIBC container types including baffle, circular, and four-panel designs

Premium Material Construction – Made from durable polyethylene that resists punctures and tears

Streamlined Loading System – Patented opening mechanism allows 40% faster filling than standard liners

Contamination Control – Seamless integration prevents material contact with outer bag surfaces

Static Dissipation Options – Available with anti-static properties for flammable materials

Technical Specifications:

| Parameter | Options |

|---|---|

| Material Grade | Virgin PE / Recycled PE blend |

| Thickness Range | 3 mil - 8 mil (customizable) |

| Maximum Load Capacity | Varies by configuration |

| Temperature Resistance | -50°C to 80°C |

| Seam Strength | ≥ 15 N/cm |

The liner's tapered bottom design facilitates complete discharge without residue, while the reinforced top spout ensures secure closure during transit. Our manufacturing process incorporates precision welding technology that creates hermetic seals for moisture-sensitive products. For food and pharmaceutical applications, we offer FDA-compliant formulations that meet stringent hygiene requirements.

Backed by Xuzhou Guozi's 15 years of industrial packaging expertise, this FIBC liner solution undergoes rigorous quality control across 12 production stages. Our Jiangsu-based facility operates with ISO-guided processes (certification available upon request), ensuring consistent performance in demanding environments. With over 200 successful implementations across Asia-Pacific markets, we provide reliable technical support and volume-based pricing structures that scale with your operational needs.

FAQ:

Q: Can these liners handle abrasive materials?

A: Yes, our 6-8 mil thickness options feature reinforced corners specifically for abrasive substances.Q: Are custom printing options available?

A: Branding and safety markings can be applied upon request.Q: What is the minimum order quantity?

A: MOQ starts at 500 units with volume discounts available.Q: How are liners secured within FIBCs?

A: They feature integrated loops compatible with standard bag tie-down systems.Q: Do you provide samples for testing?

A: Sample kits with 3 different configurations are available.Q: What packaging options do you offer?

A: Liners are compressed and boxed in weather-resistant cartons.Q: Can I get liners for conductive FIBCs?

A: Anti-static variants are available for Type C containers.Q: What's the lead time for bulk orders?

A: Standard production requires 15-20 days after confirmation.

Send Inquiry to This Supplier

You May Also Like

-

Industrial BIG BAG LINER With Moisture Barrier, Compatible With Various Bulk Material PackagingNegotiableMOQ: 1000 Pieces

-

BIG BAG LINER for FIBC Bags, Heavy-Duty Polyethylene Construction, 100-200 Micron ThicknessNegotiableMOQ: 1000 Pieces

-

Multi-Layer BIG BAG LINER for Pharmaceutical Powders, Static Dissipative Properties AvailableNegotiableMOQ: 1000 Pieces

-

Transparent BIG BAG LINER With Easy Loading Feature, FIBC PE Liner Bag Ideal for Granular and Powdered GoodsNegotiableMOQ: 1000 Pieces

-

FIBC Bulk Bag Inner Liner, PP Woven Material, Custom Sizes Available, Ideal for Grain and Powder TransportNegotiableMOQ: 500 Pieces

-

Heavy-Duty FIBC Container Liner, 2000kg Load Capacity, Anti-Static Feature for Safe Material HandlingNegotiableMOQ: 500 Pieces

-

FIBC Jumbo Bag Liner With Spout Top Design, Easy Filling and Sealing, Suitable for Building MaterialsNegotiableMOQ: 500 Pieces

-

Reusable FIBC Bag Inner Liner, UV Resistant, 100-150 Micron Thickness for Outdoor Storage ApplicationsNegotiableMOQ: 500 Pieces

-

Customizable Size FIBC Liner for Construction Industry, Fits Standard Bulk Bags, Dust-Free Cement PackagingNegotiableMOQ: 500 Pieces

-

Food Grade FIBC Liner With FDA Certification, Prevents Contamination in Sugar and Flour TransportationNegotiableMOQ: 500 Pieces