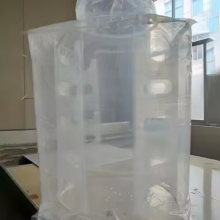

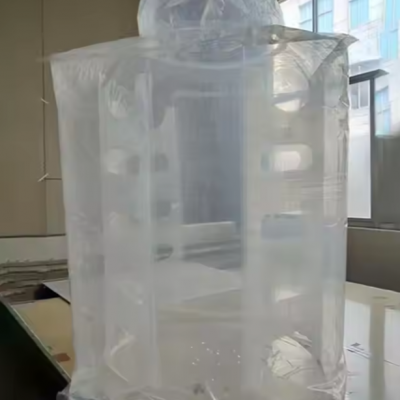

PE Inner Liner for FIBC Bags, Dustproof and Waterproof Design, Industrial Packaging Solution

It provides the best protection by being placed in Big Bag sacks.

Big Bag Nylon is used to protect the product in the bag from dirt, dust and stains. It is an indispensable product for the smooth transportation of the product. Anything that may cause liquid contact or stains is prevented from entering the product.

▪ Specially produced for big bags.

▪ It ensures that your product is kept intact.

▪ It is used safely in all areas of life and protects it from dust, moisture and dirt.

Core Technical Specifications:

Material Construction: High-density polyethylene (HDPE/LDPE blends) for tear resistance

Barrier Performance: <0.01g/m²/24hr water vapor transmission rate (WVTR)

Seam Integrity: Double heat-sealed edges withstand 15kg puncture force

Temperature Range: Stable performance from -40°C to 80°C

Operational Advantages:

Moisture Barrier: Triple-layer co-extrusion technology blocks humidity absorption during maritime transport

Static Control: Dissipative variants available for flammable material handling

Clean Discharge: Conical bottom designs prevent material retention (optional)

Compliance Ready: FDA-compliant material formulations for food/pharma applications

Our manufacturing facility in Xuzhou utilizes ISO-certified production processes (certification available upon request) with strict quality control protocols. Each liner undergoes pneumatic pressure testing at 0.3 bar for 30 minutes to ensure leak-proof performance. With over 12 years of industrial packaging expertise, we've supplied solutions to chemical, food processing, and mineral industries across 15 countries.

What Are Bulk Bag Liners?

Bulk bag liners are large, flexible bags that line the interior of FIBC bulk bags. Their prime purpose is to act as an additional protective layer, preventing direct contact between the product and the bag itself.

While bulk bags in their own right don't necessarily need protecting from the product, and vice versa, the bulk bag liner benefits are widespread.

FIBC Liner Benefits

Product Protection and Containment: Much like our shipping container liners, these FIBC liners act as an additional layer of protection, shielding your valuable products from external elements & moisture. They help maintain the integrity of your goods, reducing the risk of spoilage or damage.

Contamination Prevention: In industries where hygiene is crucial, such as food and pharmaceuticals, our liners offer a reliable barrier against potential contaminants, meeting stringent safety standards and ensuring product purity.

Increased Bag Lifespan: By minimizing wear and tear on your bulk bags, our liners extend their lifespan, leading to cost savings in the long run. The investment in quality liners pays off with reduced bag replacement expenses.

Cost-Effectiveness and Sustainability: Our liners aren't only cost-effective but also contribute to sustainable practices. They enable efficient product usage, reduce waste, and promote eco-friendly packaging solutions.

Key Features of Bulk Bag Liners

High-Quality Materials: Our liners are crafted using premium-grade materials to ensure strength and durability and designed to withstand the rigors of transportation and handling, protecting your products throughout the supply chain.

Customizable Sizes and Options:we understand that one size does not fit all. That's why our liners come in various sizes and configurations, making it easy to find the perfect fit for FIBCs.

Durability and Strength: With reinforced seams and tear-resistant construction, our FIBC Bulk Bag liners are built to handle heavy loads and challenging environments, providing peace of mind during transportation and storage.

Easy Installation and Removal: Installing our poly liners is a breeze. The user-friendly design ensures a quick setup, saving time and labor costs. Likewise, removing the liners after use is hassle-free, streamlining your operations.

Compatibility: Whether you use standard bulk bags or have specialized requirements, our liners are compatible with a wide range of bag types, ensuring seamless integration into your existing processes.

Frequently Asked Questions:

Q1: Can these liners handle powdered materials without leakage?

A: Absolutely. Our micron-sealed seams and anti-static options prevent fine powder leakage, tested with materials up to 25 microns particle size.

Q2: Are custom sizes available for non-standard FIBC containers?

A: Yes, we provide CAD-based customization with tolerances within ±2% of requested dimensions.

Q3: How do I determine the optimal thickness for my application?

A: Thickness selection depends on material abrasiveness and stacking height. Our technical team provides free consultation based on your product MSDS.

Q4: What is the lead time for bulk orders?

A: Standard orders ship within 7 working days. Customized projects require 10-15 days depending on complexity.

Q5: Do you offer liners with filling spouts?

A: Yes, we integrate various spout types (turbo, pinch-closed) positioned according to your filling system requirements.

Q6: How are the liners packaged for shipment?

A: We compress and roll-lock liners in vacuum-sealed bales (approx. 50-100 units per bale) to minimize shipping volume.

Trusted by manufacturers in over 8 industrial sectors, our PE liners have demonstrated 30% reduction in product contamination incidents during third-party audits. Contact our Jiangsu-based engineering team today for a material compatibility assessment – let us optimize your bulk packaging integrity while reducing operational losses.

Send Inquiry to This Supplier

You May Also Like

-

Heavy-Duty FIBC Container Liner, 2000kg Load Capacity, Anti-Static Feature for Safe Material HandlingNegotiableMOQ: 500 Pieces

-

FIBC Jumbo Bag Liner With Spout Top Design, Easy Filling and Sealing, Suitable for Building MaterialsNegotiableMOQ: 500 Pieces

-

Reusable FIBC Bag Inner Liner, UV Resistant, 100-150 Micron Thickness for Outdoor Storage ApplicationsNegotiableMOQ: 500 Pieces

-

Customizable Size FIBC Liner for Construction Industry, Fits Standard Bulk Bags, Dust-Free Cement PackagingNegotiableMOQ: 500 Pieces

-

Food Grade FIBC Liner With FDA Certification, Prevents Contamination in Sugar and Flour TransportationNegotiableMOQ: 500 Pieces

-

Disposable Polypropylene FIBC Liner, Cost-Effective Solution for Pharma and Food Grade Packaging NeedsNegotiableMOQ: 500 Pieces

-

Vented FIBC Liners for Aeratable Powders - Breathable Fabric Technology - Reduce Caking & MoistureNegotiableMOQ: 1000 Pieces

-

FIBC Liner for Bulk Material Handling - Durable Polyethylene Construction - Custom Sizes AvailableNegotiableMOQ: 1000 Pieces

-

Heavy-Duty FIBC Liner for Food Grade Applications - FDA Compliant - Moisture Barrier ProtectionNegotiableMOQ: 1000 Pieces

-

Food Safe FIBC Bulk Bag Liner - Odorless & Non-Toxic - Ideal for Grain, Sugar, Flour PackagingNegotiableMOQ: 1000 Pieces