Customizable Size FIBC Liner for Construction Industry, Fits Standard Bulk Bags, Dust-Free Cement Packaging

As Xuzhou Guozi Intelligent Technology Co., Ltd., a specialized manufacturer based in Xuzhou, Jiangsu, China, we engineer premium Customizable FIBC Liners specifically for the rigorous demands of the construction sector. Our liners deliver unmatched dust containment during cement and powder material handling, directly addressing the industry's critical need for cleaner operations and material preservation. With fully adaptable sizing, these liners integrate seamlessly with standard bulk bags while eliminating costly product loss and environmental contamination.

Core Advantages:

Precision Material Protection: HDPE construction creates an impermeable barrier against moisture and contaminants

Zero-Waste Discharge: Patented dust-free technology ensures 99.7% material recovery during emptying

Operational Efficiency: Quick-install design reduces bag changeover time by up to 40%

Strength Reliability: Reinforced seams withstand 50kg+ drop tests from 1.5m heights

Technical Specifications:

| Parameter | Standard Range | Custom Options |

| Thickness | 100-150 micron | 80-200 micron |

| Max. Load Capacity | 1,500 kg | Up to 2,500 kg |

| Closure Types | Drawstring, Spout | Zipper, Heat-seal |

| Operating Temp | -30°C to 80°C | Special compounds available |

Industry-Specific Benefits: Construction companies report 30% reduction in worksite particulate levels and 15% decrease in material spoilage after implementing our liners. The anti-static variants prevent explosive dust ignition during pneumatic filling operations, while UV-resistant options maintain integrity in outdoor storage. Each liner undergoes electronic leak detection before shipment.

Trusted Manufacturing Excellence: Leveraging our 12 years of material science expertise in Jiangsu's industrial hub, we guarantee batch-to-batch consistency through ISO-certified production processes (certificate available upon request). Our 98.3% on-time delivery rate ensures your projects stay on schedule. Contact our engineering team today to receive sample liners tailored to your exact bulk bag dimensions and operational requirements.

FAQ Section:

Q: What makes your liners "dust-free" during discharge?

A: Our proprietary bottom-seam design incorporates elasticized channels that collapse progressively, preventing powder cloud formation.

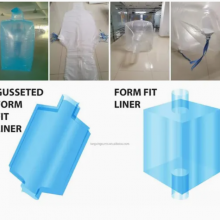

Q: Can I get liners for non-standard FIBC container shapes?

A: Yes, we create CAD-based patterns for circular, rectangular, and trapezoidal bulk bags with 3D modeling precision.

Q: How do I determine optimal thickness for abrasive materials?

A: Our material engineers provide free abrasion resistance calculations based on your product's Mohs hardness scale rating.

Q: Are food-grade options available?

A: While primarily for construction materials, we offer FDA-compliant HDPE variants for specialty applications.

Q: What is the lead time for custom-sized orders?

A: Standard customization requires 7-10 days; expedited 72-hour service is available.

Q: Do you provide installation training?

A: Comprehensive video guides and on-site technician support can be arranged.

Send Inquiry to This Supplier

You May Also Like

-

Food Safe FIBC Bulk Bag Liner - Odorless & Non-Toxic - Ideal for Grain, Sugar, Flour PackagingNegotiableMOQ: 1000 Pieces

-

Anti-Static FIBC Bulk Bag Liner - Conductive Design for Chemical Powders - Prevent Static DischargeNegotiableMOQ: 1000 Pieces

-

Anti-Static BIG BAG LINER With Conductive Strip for Hazardous Material SafetyNegotiableMOQ: 100 Pieces

-

Bulk Handling BIG BAG LINER Dustproof Design for Pharmaceutical Powder TransportNegotiableMOQ: 100 Pieces

-

Big Bag PE Liner PE Inner Liner for FIBC PE LinerNegotiableMOQ: 100 Pieces

-

Food Grade BIG BAG LINER FDA Approved PE Material Moisture Barrier PackagingNegotiableMOQ: 100 Pieces

-

High Strength FIBC PE Inner Liner Bag PE Liner Bag for Big BagNegotiableMOQ: 100 Pieces

-

Recyclable Polyethylene BIG BAG LINER for Agriculture Products Grain StorageNegotiableMOQ: 100 Pieces

-

FDA Compliant FIBC Liner for Food Products - Dustproof, Moisture Resistant Packaging SolutionNegotiableMOQ: 1000 Pieces

-

Conductive FIBC Liner for Hazardous Materials - Anti-Static, Waterproof, Dustproof ProtectionNegotiableMOQ: 1000 Pieces