Industrial Grade PE Liner for FIBC Bulk Bags, Acid and Alkali Resistance, Multi-Layer Protection

What Are Bulk Bag Liners?

Bulk bag liners are large, flexible bags that line the interior of FIBC bulk bags. Their prime purpose is to act as an additional protective layer, preventing direct contact between the product and the bag itself.

While bulk bags in their own right don't necessarily need protecting from the product, and vice versa, the bulk bag liner benefits are widespread.

FIBC Liner Benefits

Product Protection and Containment: Much like our shipping container liners, these FIBC liners act as an additional layer of protection, shielding your valuable products from external elements & moisture. They help maintain the integrity of your goods, reducing the risk of spoilage or damage.

Contamination Prevention: In industries where hygiene is crucial, such as food and pharmaceuticals, our liners offer a reliable barrier against potential contaminants, meeting stringent safety standards and ensuring product purity.

Increased Bag Lifespan: By minimizing wear and tear on your bulk bags, our liners extend their lifespan, leading to cost savings in the long run. The investment in quality liners pays off with reduced bag replacement expenses.

Cost-Effectiveness and Sustainability: Our liners aren't only cost-effective but also contribute to sustainable practices. They enable efficient product usage, reduce waste, and promote eco-friendly packaging solutions.

Key Features of Bulk Bag Liners

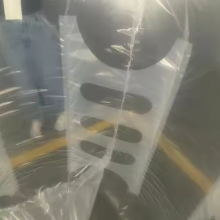

High-Quality Materials: Our liners are crafted using premium-grade materials to ensure strength and durability and designed to withstand the rigors of transportation and handling, protecting your products throughout the supply chain.

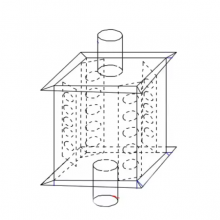

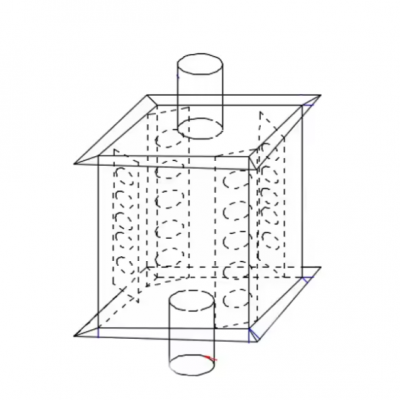

Customizable Sizes and Options:we understand that one size does not fit all. That's why our liners come in various sizes and configurations, making it easy to find the perfect fit for FIBCs.

Durability and Strength: With reinforced seams and tear-resistant construction, our FIBC Bulk Bag liners are built to handle heavy loads and challenging environments, providing peace of mind during transportation and storage.

Easy Installation and Removal: Installing our poly liners is a breeze. The user-friendly design ensures a quick setup, saving time and labor costs. Likewise, removing the liners after use is hassle-free, streamlining your operations.

Compatibility: Whether you use standard bulk bags or have specialized requirements, our liners are compatible with a wide range of bag types, ensuring seamless integration into your existing processes.

Engineered with multi-layer technology, this liner provides:

Chemical resilience for handling acids, alkalis, and aggressive materials

Reinforced barrier protection against moisture and contamination

Custom-fit solutions for various FIBC configurations

Technical specifications include:

| Feature | Benefit |

| Material Composition | Premium polyethylene with enhanced molecular density |

| Layer Structure | 3-5 layer co-extrusion (customizable) |

| Thickness Range | 120-200 microns (adjustable per requirement) |

| Temperature Tolerance | -50°C to 80°C operational range |

The liner's unique construction offers:

Reduced product loss through advanced sealing technology

Extended service life even with abrasive materials

Compatibility with both open-top and closed-top FIBC designs

Backed by Xuzhou Guozi's decade of manufacturing expertise in Jiangsu's industrial hub, this liner undergoes rigorous quality control processes. Our production facility utilizes precision extrusion technology to ensure consistent thickness and material homogeneity across all layers. The chemical resistance properties are validated through in-house testing with common industrial compounds including:

Sulfuric acid solutions (up to 50% concentration)

Sodium hydroxide (up to 40% concentration)

Organic solvents and salts

For bulk handling operations in chemical, pharmaceutical, and food processing industries, this liner provides measurable operational advantages:

Cost reduction through minimized product contamination

Safety enhancement by preventing container degradation

Regulatory compliance for sensitive material handling

Trusted by industrial partners across Asia, our liners are manufactured under strict process controls at our Xuzhou facility. We offer technical consultation to match liner specifications with your specific FIBC dimensions and material characteristics. Contact our engineering team today to request material samples or discuss custom configuration options.

Frequently Asked Questions:

Q: Can this liner handle concentrated hydrochloric acid?

A: The standard formulation resists up to 30% HCl concentration. For stronger acids, we recommend our specialty reinforced version.

Q: Are food-grade options available?

A: Yes, we offer FDA-compliant formulations suitable for food and pharmaceutical applications.

Q: How do I determine the correct liner size?

A: Provide your FIBC dimensions and filling method. Our team will recommend optimal sizing.

Q: What is the minimum order quantity?

A: MOQ starts at 500 units with volume discounts available.

Q: Can liners be pre-fitted in FIBC bags?

A: Yes, we offer pre-installed liner solutions for automated filling lines.

Q: Do you provide technical data sheets?

A: Complete material specifications and test reports are available upon request.

Send Inquiry to This Supplier

You May Also Like

-

Transparent BIG BAG LINER With Easy Loading Feature, FIBC PE Liner Bag Ideal for Granular and Powdered GoodsNegotiableMOQ: 1000 Pieces

-

FIBC Bulk Bag Inner Liner, PP Woven Material, Custom Sizes Available, Ideal for Grain and Powder TransportNegotiableMOQ: 500 Pieces

-

Heavy-Duty FIBC Container Liner, 2000kg Load Capacity, Anti-Static Feature for Safe Material HandlingNegotiableMOQ: 500 Pieces

-

FIBC Jumbo Bag Liner With Spout Top Design, Easy Filling and Sealing, Suitable for Building MaterialsNegotiableMOQ: 500 Pieces

-

Reusable FIBC Bag Inner Liner, UV Resistant, 100-150 Micron Thickness for Outdoor Storage ApplicationsNegotiableMOQ: 500 Pieces

-

Customizable Size FIBC Liner for Construction Industry, Fits Standard Bulk Bags, Dust-Free Cement PackagingNegotiableMOQ: 500 Pieces

-

Food Grade FIBC Liner With FDA Certification, Prevents Contamination in Sugar and Flour TransportationNegotiableMOQ: 500 Pieces

-

Disposable Polypropylene FIBC Liner, Cost-Effective Solution for Pharma and Food Grade Packaging NeedsNegotiableMOQ: 500 Pieces

-

Vented FIBC Liners for Aeratable Powders - Breathable Fabric Technology - Reduce Caking & MoistureNegotiableMOQ: 1000 Pieces

-

FIBC Liner for Bulk Material Handling - Durable Polyethylene Construction - Custom Sizes AvailableNegotiableMOQ: 1000 Pieces