Middle Mesh Sleeve 300–400 Steel Wire Rope Sleeve | Heavy‑Duty Cable Protection & Lifting Sleeve

Cable sock, also known as a pulling sock or conductor sock, is a specialized traction tool installed at the end of a cable. It is woven from high-strength steel wire rope or stainless steel wire into a sock-like structure that tightens further under tension, thereby firmly gripping the cable and enabling safe pulling.

🔧 Structure and Principle

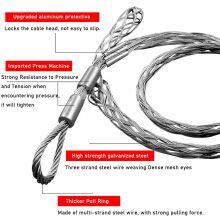

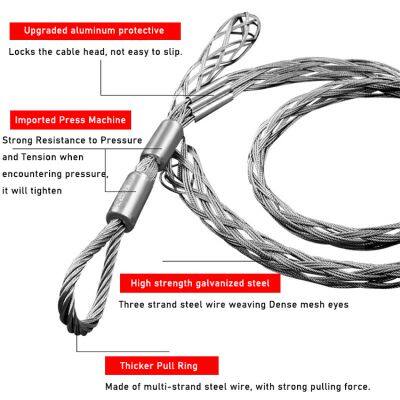

• Material: Typically woven from double-layer galvanized or stainless steel high-strength steel wire rope, with an openable sock mouth for easy insertion of the cable.

• Structure: One or both ends are pressed into rings, double ears, or other connection loops for attaching the pulling rope or pulling equipment.

• Principle: Relies on the radial elasticity of the mesh structure; when force is applied, it automatically contracts and tightens around the cable, providing reliable pulling force and anti-slip capability.

🎯 Main Applications

1. Power Line Stringing: Used in overhead line construction to pull ACSR (aluminum conductor steel reinforced), insulated conductors, ground wires, etc.

2. Communication Installation: Used to pull optical fibers, optical cables, and other communication lines, and can smoothly pass through stringing blocks.

3. Equipment Maintenance: Used for replacing and laying cables inside power plants and substations.

4. Special Applications: As a hanging net or protective sleeve for suspending or protecting streetlight feeder cables, drainage pump cables, high-pressure oil pipes, etc., preventing wear and excessive stress.

✨ Key Features

• High Safety: Made of high-strength steel wire rope with breaking loads reaching tens of tons, far exceeding ordinary hemp ropes or iron wires.

• Strong Anti-Slip: The mesh structure automatically tightens under force, effectively preventing slippage.

• Cable Protection: The contact surface is relatively soft, significantly reducing damage to the cable’s outer sheath compared to direct pulling with steel wire rope.

• Easy Operation: Light weight, good radial flexibility, easy to install and remove, and reusable.

• Strong Adaptability: Can smoothly pass through various pulleys and curved conduits, suitable for medium- and short-distance pulling operations.

📏 How to Select

1. Match Cable Diameter: Choose based on the outer diameter of the cable or optical cable. Sock specifications usually cover a range (e.g., 38–60 mm); ensure the cable’s outer diameter falls within this range—too large causes slipping, too small prevents proper fitting or damages the cable.

2. Match Pulling Force: Select according to the maximum pulling force required. Ensure the sock’s rated breaking load is much greater than the maximum pulling force during construction, leaving sufficient safety margin.

3. Match Usage Environment:

• Outdoor/Moist Environments: Prefer stainless steel material for corrosion resistance.

• Long-Term Submersion: Must use all-stainless steel socks.

• Special Media: For protecting high-pressure oil pipes, use dedicated oil pipe socks.

📝 Usage Methods

1. Traction End Installation (Standard Method)

1. Inspection: Confirm the sock specification matches the cable and check for broken wires, rust, or other defects.

2. Insertion: Place one end of the cable into the sock through the open mouth, ensuring the sock covers the section of cable that will bear the load.

3. Connection: Connect the pulling rope or pulling equipment to the connection loop at the sock’s end.

4. Pre-Tightening: Gently pull the rope to initially tighten the sock and confirm correct positioning.

5. Pulling: During pulling, keep the cable, sock, and pulling rope as straight as possible; avoid sudden stops, rapid acceleration, or lateral forces.

2. Semi-Open Sock Installation (Wrap Method)

1. Wrapping: Wrap the semi-open sock around the cable like a piece of cloth.

2. Threading: Pull the pulling rope out from one end of the sock, then thread it in and out sequentially across the sock like tying shoelaces, gradually tightening it.

3. Fixing: After the rope exits, wrap the remaining rope around the cable tail several times and tie a knot to secure it.

4. Completion: Keep the mesh even while tightening to ensure uniform force distribution.

3. Steel Wire Rope Connection Method

1. Insertion: Insert the two steel wire ropes to be connected into opposite ends of the hollow sock.

2. Pulling: Through pulling, the sock contracts and tightly clamps the steel wire ropes, achieving flexible connection.

3. Removal: Push the sock in reverse to easily disassemble it for reuse.

⚠️ Safety Precautions

• No Overloading: Ensure the pulling force remains within the sock’s rated load capacity; overloading is strictly prohibited.

• Condition Check: Before each use, inspect the sock for damage; immediately discard if broken wires, severe rust, or cracks at crimp joints are found.

• Standard Operation: During pulling, personnel must not stay or walk under the pulling rope or cable.

• Avoid Damage: Prevent the sock from rubbing against sharp objects to avoid damaging the cable’s outer sheath.

• Environmental Adaptation: In moist or corrosive environments, select socks with appropriate protection levels (e.g., stainless steel).

• Professional Construction: For high-voltage, large-section cables, or complex environments, work should be carried out by professionals with a specific plan.

Product Description

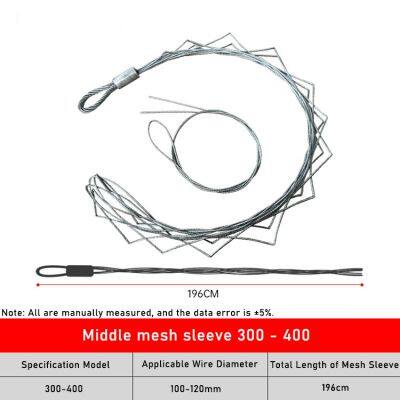

Discover the Middle Mesh Sleeve 300–400, a premium steel wire rope sleeve engineered for demanding lifting, towing, and cable pulling tasks. Crafted from high‑strength galvanized steel, this mesh sleeve features tightly woven multi‑strand wire construction, delivering exceptional wear resistance and tensile strength for long‑lasting performance in harsh environments.

With a total length of 196 cm and compatibility for wire diameters of 100–120 mm, the sleeve ensures a secure grip and reliable protection during installation, hoisting, or pulling operations. Its one‑end metal connector and black sealed cap provide quick attachment and stability, while the uniform coil design maximizes storage efficiency and usability on job sites.

Ideal for construction, mining, marine, and industrial applications, this sleeve supports safe handling of heavy cables and ropes. Each unit is hand‑measured, with a tolerance of ±5%, guaranteeing precision within industry standards.

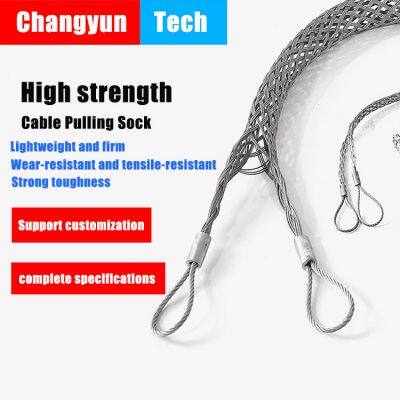

Combine it with our cable‑pulling grips and basket‑style galvanized cable grips for versatile style selection to meet diverse project requirements. Our range also includes high‑strength cable pulling socks from Changyun Tech — lightweight yet firm, wear‑resistant, tensile‑resistant, and customizable to suit complete specifications. Whether you need a single protective device or a full suite of cable management tools, our products deliver industrial‑grade reliability worldwide.

Send Inquiry to This Supplier

You May Also Like

-

Changyun Tech Cable Pulling Tools & Cable Mesh 300–400 | Galvanized Steel Grips, Socks & Sleeves for Heavy‑Duty Cable InstallationUS$ 20 - 100MOQ: 1 Combo

-

Changyun Tech Cable Pulling Grip, Mesh Sleeve & Sock Set | Galvanized Steel Cable Management Tools for Construction & RiggingUS$ 20 - 100MOQ: 1 Combo

-

Changyun Tech Cable Pulling Grip, Mesh Sleeve & Sock | Galvanized Steel Cable Management Tools for Construction & RiggingUS$ 20 - 100MOQ: 1 Combo

-

Dual‑Head Cable Pulling Net & High‑Strength Galvanized Steel Cable Pulling Sock | Industrial Cable Handling Tools for 10KV High‑Voltage ApplicationsUS$ 20 - 100MOQ: 1 Combo

-

Cable Pulling Net, Grip & High‑Strength Galvanized Steel Puller | Industrial Tools for 10kV High‑Voltage Cable InstallationUS$ 20 - 100MOQ: 1 Combo

-

Single-Head Cable Pulling Mesh Sleeve & High-Strength Galvanized Steel Cable Pulling GripUS$ 20 - 100MOQ: 1 Combo

-

Single-Head Cable Pulling Grip, Galvanized Steel Grip & High-Strength Mesh SleevesUS$ 20 - 100MOQ: 1 Combo

-

Galvanized Cable Pulling Grip & Metal Mesh Sockets | Industrial Cable Protection & Pulling Tools for ConstructionUS$ 20 - 100MOQ: 1 Combo

-

Galvanized Steel Grip & Changyun Tech Cable Pulling Sock | Industrial Cable Handling Tools for Electrical & Construction ProjectsUS$ 20 - 100MOQ: 1 Combo

-

Two-Head Cable Mesh Sleeve Connector, Galvanized Steel Grip & Changyun Tech Cable Pulling SockUS$ 20 - 100MOQ: 1 Combo