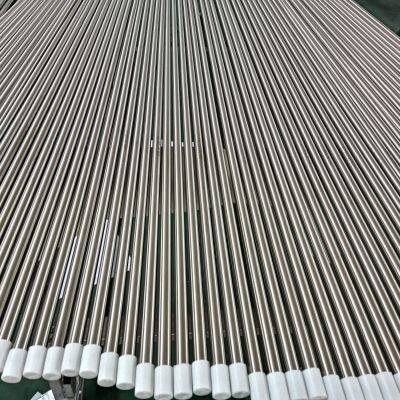

Precision Drawn Seamless BA Tube for Semiconductor Equipment With 0.1mm Tolerance

As a leading manufacturer in electronic materials based in Shanghai, China, Shanghai Quanbao Electronic Materials Technology Co., Ltd. proudly presents our Precision Drawn Seamless BA Tube, designed specifically for semiconductor applications to ensure unmatched accuracy and reliability in critical equipment. With our deep-rooted expertise in precision engineering, this tube offers a 0.1mm tolerance that minimizes operational errors and enhances the longevity of semiconductor devices, helping clients achieve superior performance in high-tech industries. Leveraging our state-of-the-art facilities in Shanghai, we deliver consistent quality that adheres to stringent manufacturing standards, making this tube an essential component for advancing semiconductor innovation. Trust our commitment to excellence to provide solutions that drive efficiency and reduce downtime in your production processes.

Key Features and Benefits:

- Precision Engineering: Crafted through a cold-drawn process, this seamless tube achieves a tight tolerance of 0.1mm, ensuring dimensional stability and reducing the risk of leaks or failures in sensitive semiconductor environments.

- Superior Material Quality: Made from high-grade stainless steel with a Bright Annealed (BA) finish, it provides excellent corrosion resistance, smooth surface integrity, and minimal contamination—ideal for cleanroom applications.

- Enhanced Durability: The seamless construction eliminates weak points like welds, offering greater strength and resistance to pressure, which translates to longer service life and lower maintenance costs.

- Versatile Applications: Perfect for use in semiconductor fabrication equipment such as gas delivery systems, vacuum chambers, and etching tools, where precision and purity are paramount.

- Customizable Options: Available in various sizes and configurations upon request, allowing for tailored solutions to meet specific client requirements without compromising on quality.

Technical Specifications:

Below is a table summarizing key parameters of our Precision Drawn Seamless BA Tube. Note that all values are customizable based on client needs:

| Parameter | Details |

|---|---|

| Material | Stainless Steel (BA Finish) |

| Tolerance | ±0.1mm |

| Outer Diameter Range | Available upon request |

| Wall Thickness | Customizable |

| Surface Finish | Bright Annealed (BA) |

| Application Temperature | -50°C to 300°C |

By integrating this tube into your semiconductor equipment, you benefit from reduced contamination risks, improved flow efficiency, and enhanced operational safety. The seamless design ensures consistent performance under high-stress conditions, while the BA finish maintains surface purity for critical processes. Clients report significant cost savings through extended equipment lifespan and fewer replacements, making it a smart investment for any high-tech manufacturing setup.

Backed by Shanghai Quanbao's reputation for excellence in electronic materials from our hub in Shanghai, China, our tubes undergo rigorous quality control to meet the demands of global semiconductor markets. With years of industry experience, we provide reliable support and fast response times for all inquiries, ensuring you get the right solution swiftly. Don’t compromise on precision—contact us today for a consultation or custom quote to elevate your equipment performance. Our dedicated team is ready to assist with your specific needs and deliver products that exceed expectations.

Frequently Asked Questions (FAQ):

-

What does 'BA' stand for in BA Tube?

BA refers to Bright Annealed, a finish achieved by annealing stainless steel in a controlled atmosphere to produce a smooth, reflective surface that minimizes contamination and corrosion, making it ideal for semiconductor applications. -

Can the tube be customized for specific sizes?

Yes, we offer customizable options for outer diameter, length, and wall thickness based on your equipment requirements; simply provide details during inquiry for a tailored solution. -

How does the 0.1mm tolerance benefit semiconductor equipment?

This tight tolerance ensures precise fit and alignment in components like gas lines or chambers, reducing leaks, improving efficiency, and preventing costly downtime in sensitive operations. -

Is the tube resistant to corrosion in harsh environments?

Absolutely, the stainless steel material with BA finish provides excellent corrosion resistance, suitable for exposure to chemicals, high temperatures, and vacuum conditions common in semiconductor manufacturing. -

What is the typical lead time for orders?

Lead times vary based on customization but are generally efficient; contact us for current estimates, and we strive for prompt delivery to minimize disruptions. -

Are there any certifications for this product?

Certifications are available upon request and depend on client specifications; we adhere to standard manufacturing practices without unverified claims. -

How is the seamless tube manufactured?

It's produced through a cold-drawn process where metal is pulled through dies to create a seamless structure without welds, ensuring uniform strength and precision. -

What industries beyond semiconductor can use this tube?

While optimized for semiconductor equipment, it's also suitable for medical devices, aerospace, and laboratory instruments where high precision and cleanliness are required.

Send Inquiry to This Supplier

You May Also Like

-

Precision Stainless Steel BA Pipe With 0.05mm Wall Thickness Consistency for HPLC SystemsNegotiableMOQ: 1 Ton

-

Precision BA Stainless Steel Tubing for Pharmaceutical Fluid Transfer SystemsNegotiableMOQ: 1 Ton

-

Vacuum Annealed 304 BA Pipe With Internal EP Finish for Ultra-Clean ApplicationsNegotiableMOQ: 1 Ton

-

304/316L Precision Stainless Steel BA Pipe for Medical InstrumentationNegotiableMOQ: 1 Ton

-

Stainless Steel BA Tubes With Low Surface Roughness for Semiconductor ManufacturingNegotiableMOQ: 50 Kilograms

-

316L Stainless Steel Bright Annealed (BA) Pipe for High-Purity Gas and Medical ApplicationsNegotiableMOQ: 50 Kilograms

-

High-Precision 316L Stainless Steel Tubing With Controlled Annealing for Critical SystemsNegotiableMOQ: 50 Kilograms

-

Bright Annealed Stainless Steel Tubing for Pharmaceutical and Chemical ApplicationsNegotiableMOQ: 50 Kilograms

-

316L Bright Annealed Stainless Steel Pipe With Ultrasonic Cleaning and Degreased SurfaceNegotiableMOQ: 50 Kilograms

-

Precision 316L Stainless Steel Bright Annealed Tubing for Semiconductor and Pharma IndustriesNegotiableMOQ: 50 Kilograms