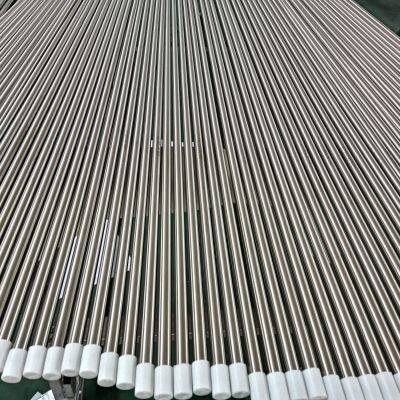

Bright Annealed Stainless Steel Tubing for Pharmaceutical and Chemical Applications

Shanghai Quanbao Electronic Materials Technology Co., Ltd. presents premium Bright Annealed Stainless Steel Tubing engineered for critical applications in pharmaceutical manufacturing and chemical processing industries. Our tubing combines exceptional purity standards with robust mechanical properties to ensure reliable performance in sterile environments and aggressive chemical exposures.

Manufactured through controlled annealing processes, these tubes deliver:

- Optimal surface integrity for contamination-free fluid transfer

- Enhanced corrosion resistance against acidic/alkaline substances

- Superior dimensional consistency for precision installations

Below are key technical specifications available for customization:

| Parameter | Range | Notes |

|---|---|---|

| Outer Diameter | 3mm - 150mm | Tighter tolerances optional |

| Wall Thickness | 0.5mm - 10mm | Varies with diameter |

| Surface Roughness | ≤0.8μm Ra | Bright annealed finish |

| Hardness | HRB 85 max | Annealed condition |

Key operational advantages include:

- Sterility Assurance: Non-porous surface prevents bacterial colonization, meeting pharmaceutical hygiene requirements

- Chemical Compatibility: Resists chlorides, solvents, and cleaning agents used in CIP processes

- Structural Reliability: Maintains integrity under thermal cycling and pressure variations

Applications extend beyond core pharmaceutical uses to include:

- Bioreactor fluid lines

- Solvent transfer systems

- High-purity gas delivery

- Analytical instrumentation

Frequently Asked Questions

Q: What standards govern your manufacturing process?

A: We adhere to industry-accepted specifications for material composition and dimensional accuracy. Specific certifications can be discussed upon request.

Q: Can tubing be supplied with end finishes?

A: Yes, we offer options including deburred ends, square-cut finishes, or chamfered edges to facilitate installation.

Q: How does bright annealing improve performance?

A: The oxygen-free annealing process creates a chromium oxide layer that enhances corrosion resistance while maintaining a clean, passive surface.

Q: What is the lead time for custom diameters?

A: Standard sizes ship within 5-7 days. Non-standard dimensions typically require 2-3 weeks for production.

Q: Do you provide material traceability?

A> Material batch traceability documentation is available when required for quality assurance protocols.

Partner with Shanghai Quanbao for tubing solutions that enhance system reliability while reducing maintenance costs. Contact our technical team to discuss your application requirements and request material samples for evaluation. Our responsive customer service ensures prompt support throughout your procurement process.

Send Inquiry to This Supplier

You May Also Like

-

High-Precision 316L Stainless Steel Tubing With Controlled Annealing for Critical SystemsNegotiableMOQ: 50 Kilograms

-

High-Pressure Double Ferrule Ball Valve With PTFE Seal and Bi-Directional SealingNegotiableMOQ: 10 Pieces

-

316 Stainless Steel Cylinder Adapter for Custom Applications - Precision Engineered FittingNegotiableMOQ: 10 Pieces

-

High-Quality Stainless Steel Cylinder Adapter Used in Pneumatic Equipment for Industrial ApplicationsNegotiableMOQ: 10 Pieces

-

Leak-Proof Stainless Steel Cylinder Adapter With Easy Installation for Gas Cylinder SystemsNegotiableMOQ: 10 Pieces

-

1/4 Inch Stainless Steel Cylinder Adapter for Hydraulic Systems - Standard Size FittingNegotiableMOQ: 10 Pieces

-

Stainless Steel Cylinder Adapter Designed for Automotive Hydraulic Systems and Heavy MachineryNegotiableMOQ: 10 Pieces

-

Stainless Steel Cylinder Adapter Compatible With Parker Cylinders in Various SizesNegotiableMOQ: 10 Pieces

-

Medical-Grade Stainless Steel Cylinder Adapter for Equipment in Healthcare IndustryNegotiableMOQ: 10 Pieces

-

Durable Stainless Steel Cylinder Adapter for Marine Applications - Saltwater Resistant DesignNegotiableMOQ: 10 Pieces