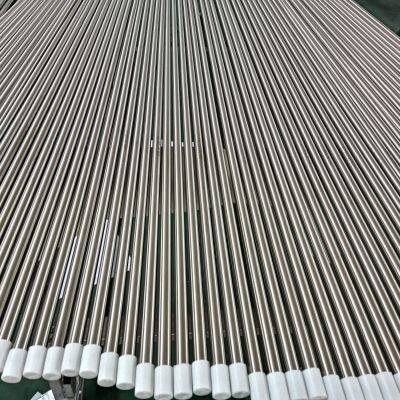

316L Stainless Steel Bright Annealed (BA) Pipe for High-Purity Gas and Medical Applications

316L Stainless Steel Bright Annealed (BA) Pipes are ultra-low carbon stainless steel pipes (C≤0.03%) with superior corrosion resistance, particularly suitable for conveying corrosive gases and medical gases. Manufactured through a specialized bright annealing process in an inert or reducing atmosphere, these pipes feature a high-gloss, oxide-free surface with excellent surface finish and cleanliness. With precise dimensional tolerances and high-purity surface requirements, they are the ideal material for critical applications in semiconductor, pharmaceutical, food, and high-tech industries.

| Element | 316L Composition | Material Standards |

|---|---|---|

| Carbon (C) | ≤0.035% | Domestic: GB/T 14976-2022, GB/T 12771-2000 |

| Silicon (Si) | ≤1.00% | International: ASTM A269, ASTM A270, ASME A270-BPE |

| Manganese (Mn) | ≤2.0% | European: EN10216-5, EN10305-1 |

| Phosphorus (P) | ≤0.045% | Japanese: JIS G4305, JIS G3447 |

| Sulfur (S) | ≤0.030% | |

| Nickel (Ni) | 10.0-14.0% | |

| Chromium (Cr) | 16.0-18.0% | |

| Molybdenum (Mo) | 2.0-3.0% |

Other Available Materials: 304, 304L, 316, 316Ti, 321, 347H, 310S, 904L, 2205, 2507, 2520, C276

Dimensions & Tolerances| Parameter | Specification Range | Tolerance |

|---|---|---|

| Outer Diameter (OD) | 3mm - 146mm | ±0.05mm (Min. 0.02mm) |

| Wall Thickness (WT) | 0.5mm - 6mm | ±0.05mm |

| Length | 1000mm - 12000mm (Customizable) | ±1mm |

| Shape | Round Pipes (Primary) |

Imperial Size Reference:

1/4" (6.35mm OD), 3/8" (9.53mm), 1/2" (12.70mm), 3/4" (19.05mm), 1" (25.40mm)

1-1/2" (38.10mm), 2" (50.80mm), 2-1/2" (63.5mm), 3" (76.20mm), 4" (101.60mm), 5" (152.4mm)

| Parameter | Specification | Process |

|---|---|---|

| Surface Roughness (Ra) | Outer: ≤0.4μm Inner (BA Grade): ≤0.3μm Inner (EP Grade): ≤0.25μm High Clean (Food/Pharma): ≤0.8μm | 1. Bright Annealing: Heat treatment in H₂/N₂/Ar atmosphere 2. Mechanical Polishing: Gradual fine-grit polishing 3. Ultrasonic Cleaning: SC2286 cleaning agent 4. Degreasing: Oil content ≤120mg/m² |

| Surface Treatment | Oxide-free, bright metallic finish |

| Property | 316L BA Pipe |

|---|---|

| Tensile Strength | ≥480 MPa (Controllable: 626-1270 MPa) |

| Yield Strength | ≥175 MPa |

| Elongation | ≥30% (Controllable: 40-65%) |

| Hardness | HRC 16-38 (Controllable: HV160-400) |

| Density | 7.98 g/cm³ |

Electrical Resistivity: 74×10⁻⁸ Ω·m

Specific Heat Capacity: 0.5 Kj/(Kg·°C) (0-100°C)

Oxidation Critical Temperature: Continuous use 900°C, Intermittent use 810°C

Corrosion Resistance: Excellent, especially in chloride environments (approx. 30% lower corrosion rate in 5% NaCl solution)

Tests: Intergranular corrosion test (oxalic acid etch), Salt spray test (GB/T 10125-2012)

Hydrostatic Test: 2.5x working pressure, hold 5 seconds (leak-free)

Non-Destructive Testing: Eddy current, Ultrasonic thickness measurement

Hardness Test: Cold-drawn ≤250 HBW, Solution-treated ≤217 HBW

Food/Pharma Compliance: GB 4806.9-2016 migration test requirements

Superior Corrosion Resistance: Ideal for chloride and acidic environments

High Surface Purity: Oil-free, contaminant-free surface suitable for high-purity applications

Excellent Dimensional Precision: Tight tolerances for critical installations

Versatile Material Options: Available in various stainless steel grades

Industry Compliance: Meets international standards for multiple sectors

Semiconductor Industry: Ultra-high purity gas delivery systems

Pharmaceutical/Biotech: Medical devices, bioprocessing equipment

Food & Beverage: Sanitary process piping, purification systems

Instrumentation: Precision instrument and analytical system piping

Chemical Processing: Corrosive fluid and gas transfer lines

Energy Sector: Hydrogen energy, solar, photovoltaic systems

Aerospace: High-precision tubing, hydraulic systems

Protective Packaging: Individual pipe bagging, end caps, anti-static bags

Secure Shipping: Bubble wrap cushioning, wooden crates or woven bags

Clear Marking: Spray-coded material, size, and specification information

Storage: Dry, ventilated environment away from corrosive substances

Send Inquiry to This Supplier

You May Also Like

-

Stainless Steel BA Tubes With Low Surface Roughness for Semiconductor ManufacturingNegotiableMOQ: 50 Kilograms

-

High-Pressure Double Ferrule Ball Valve With PTFE Seal and Bi-Directional SealingNegotiableMOQ: 10 Pieces

-

316 Stainless Steel Cylinder Adapter for Custom Applications - Precision Engineered FittingNegotiableMOQ: 10 Pieces

-

High-Quality Stainless Steel Cylinder Adapter Used in Pneumatic Equipment for Industrial ApplicationsNegotiableMOQ: 10 Pieces

-

Leak-Proof Stainless Steel Cylinder Adapter With Easy Installation for Gas Cylinder SystemsNegotiableMOQ: 10 Pieces

-

1/4 Inch Stainless Steel Cylinder Adapter for Hydraulic Systems - Standard Size FittingNegotiableMOQ: 10 Pieces

-

Stainless Steel Cylinder Adapter Designed for Automotive Hydraulic Systems and Heavy MachineryNegotiableMOQ: 10 Pieces

-

Stainless Steel Cylinder Adapter Compatible With Parker Cylinders in Various SizesNegotiableMOQ: 10 Pieces

-

Medical-Grade Stainless Steel Cylinder Adapter for Equipment in Healthcare IndustryNegotiableMOQ: 10 Pieces

-

Durable Stainless Steel Cylinder Adapter for Marine Applications - Saltwater Resistant DesignNegotiableMOQ: 10 Pieces