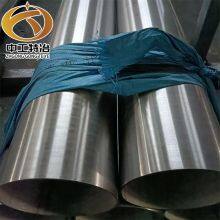

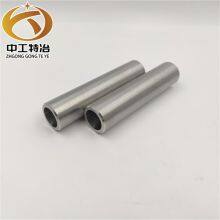

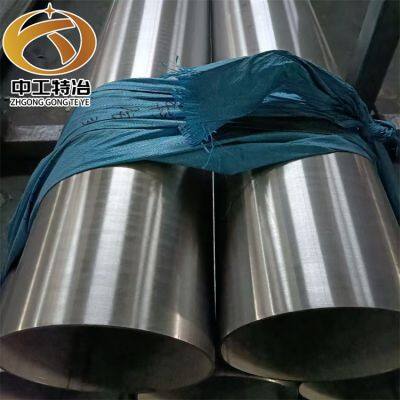

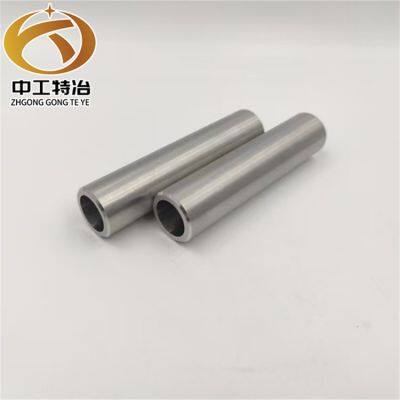

Durable Titanium Alloy Tube for Aerospace and Medical Applications With Custom Processing

Engineered for mission-critical applications, our titanium alloy tubes deliver exceptional strength-to-weight ratios and unparalleled corrosion resistance. Manufactured by Jiangsu Zhonggongte Metallurgical Technology, these precision components meet stringent aerospace and medical industry requirements while offering complete custom processing flexibility.

With ISO9001 certified production and global export capabilities spanning over 100 countries, we provide reliable titanium solutions for:

Aircraft hydraulic systems requiring lightweight durability

Medical implant applications demanding biocompatibility

Chemical processing equipment needing corrosion resistance

High-performance racing components

Core Technical Specifications:

| Property | Value Range | Testing Standard |

|---|---|---|

| Tensile Strength | 895-1035 MPa | ASTM E8 |

| Density | 4.43 g/cm³ | ASTM B311 |

| Corrosion Resistance | Excellent in chloride environments | ASTM G48 |

Our manufacturing advantages include:

Cold drawing processes that enhance mechanical properties

Ultrasonic testing for defect detection

Customizable chemical composition control (±0.5%)

Multi-stage annealing for optimal grain structure

"The dimensional accuracy and surface finish consistency have significantly reduced our machining time by approximately 30% in orthopedic implant production."

- Medical Device Manufacturer, Germany

Frequently Asked Questions:

Q: What titanium grades are available?

A: We primarily supply Grade 5 (Ti-6Al-4V) and Grade 2 (commercially pure). Other grades available upon request.

Q: Can you meet AMS and ASTM specifications?

A: Yes, we regularly produce tubes conforming to AMS 4928, ASTM B338, and ISO 5832 standards.

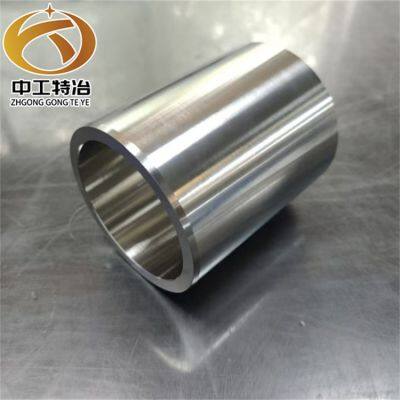

Q: What surface finishes do you offer?

A: Options include pickled, mechanically polished (Ra ≤ 0.4μm), and medical-grade electropolished surfaces.

Q: What is your minimum order quantity?

A: MOQ varies based on specifications. Standard sizes start from 50kg, custom sizes from 100kg.

Q: How do you ensure material traceability?

A: Full mill certification with heat number traceability is provided for all shipments.

With shipments processed through Shanghai and Tianjin ports, we guarantee on-time delivery to global destinations. Our technical team provides comprehensive material selection guidance and application engineering support throughout your project lifecycle.

Request a free material sample kit with test certificates today. Our specialists are ready to discuss your specific tolerance requirements (+0.05/-0.00mm achievable) and develop custom processing solutions for your most challenging applications.

Send Inquiry to This Supplier

You May Also Like

-

Titanium Alloy Bar Featuring Excellent Fatigue Resistance for Automotive Components and Heavy MachineryNegotiableMOQ: 1 Ton

-

Durable Titanium Alloy Bar for Marine Equipment and Chemical Processing IndustryNegotiableMOQ: 1 Ton

-

Durable Titanium Alloy Bar for Marine Equipment and Chemical Processing IndustryNegotiableMOQ: 1 Ton

-

Lightweight Titanium Alloy Bar Compatible With CNC Machining Tools, Custom Sizes AvailableNegotiableMOQ: 1 Ton

-

High-Strength Titanium Alloy Bar With Superior Corrosion Resistance for Aerospace and Medical ApplicationsNegotiableMOQ: 1 Ton

-

Cold-Rolled Titanium Alloy Pipe TA7 With 0.5mm-10mm Diameter RangeNegotiableMOQ: 1 Ton

-

Custom-Cut Titanium Alloy Pipe With Full Dimensional Inspection ReportNegotiableMOQ: 1 Ton

-

High-Strength Titanium Alloy Bar With Superior Corrosion Resistance for Aerospace and Medical ApplicationsNegotiableMOQ: 1 Ton

-

Welded Titanium Alloy Pipe TA3/TA4 With Mill Test Report ComplianceNegotiableMOQ: 1 Ton

-

Grade 5 Titanium Alloy Pipe TB6 for High-Pressure Chemical ProcessingNegotiableMOQ: 1 Ton