Durable Titanium Alloy Bar for Marine Equipment and Chemical Processing Industry

Experience unparalleled durability and reliability with our Titanium Alloy Bar, expertly engineered for the demanding environments of marine equipment and chemical processing industries. This high-performance bar delivers exceptional corrosion resistance to harsh elements like saltwater and aggressive chemicals, ensuring long-term integrity and reduced maintenance costs. Manufactured with precision and backed by ISO9001 certification, it offers a sustainable solution for critical applications where failure is not an option. Ideal for components such as valves, pumps, and structural parts, this bar enhances operational efficiency and safety in challenging settings. Trust in our globally recognized supply chain to deliver consistent quality that meets rigorous industry demands.

Our Titanium Alloy Bar stands out due to its advanced material properties and versatile applications. Key features include:

Superior Corrosion Resistance: Engineered to withstand prolonged exposure to corrosive agents, making it perfect for marine and chemical environments where standard metals degrade quickly.

High Strength-to-Weight Ratio: Titanium alloy provides exceptional tensile strength while remaining lightweight, facilitating easier installation and reducing structural load.

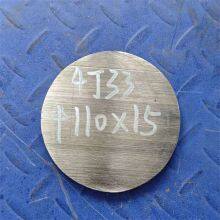

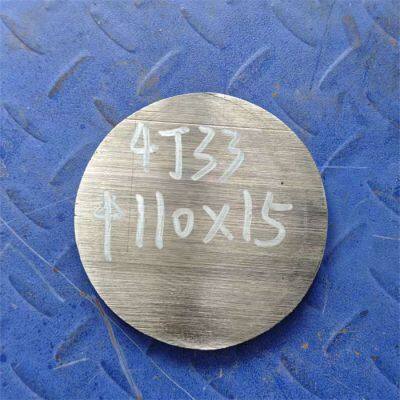

Customizable Dimensions: Available in a wide range of sizes to suit specific project requirements, ensuring optimal fit and performance.

Thermal Stability: Maintains integrity under extreme temperatures, from -50°C to 600°C, suitable for diverse industrial processes.

Technical specifications highlight the bar's robustness and adaptability. Below is a summary of key parameters:

| Parameter | Specification |

|---|---|

| Material Composition | Titanium Alloy (Grade 5 equivalent) |

| Diameter Range | 10mm - 200mm (customizable) |

| Standard Length | Up to 6000mm (tailored options) |

| Tolerance | ±0.1mm precision |

| Density | Approx. 4.5 g/cm³ |

Advantages for clients include extended equipment lifespan, minimized downtime, and enhanced safety compliance. For instance, in chemical processing plants, the bar's resistance to acids and alkalis prevents contamination and leaks, while in marine settings, it combats saltwater erosion, reducing replacement frequency. This translates to cost savings of up to 30% in maintenance over time. Additionally, the customizable nature allows for seamless integration into existing systems, supporting quick upgrades without major overhauls.

Elevate your industrial operations with a product that combines cutting-edge material science with proven reliability. Backed by Jiangsu Zhonggongte's extensive export experience and ISO9001 assurance, we guarantee timely delivery and responsive support. Reach out today for a customized quote or to discuss your specific needs—our team is ready to provide solutions that drive your success forward.

Frequently Asked Questions (FAQ):

Q: What industries benefit most from this titanium bar?

A: It is ideal for marine equipment (e.g., ship components) and chemical processing (e.g., reactor parts), due to its corrosion resistance and durability.Q: How does the corrosion resistance compare to other materials?

A: Titanium alloy outperforms stainless steel and aluminum in harsh environments, offering superior longevity against saltwater and chemicals.Q: Can I request specific sizes or shapes?

A: Yes, dimensions are customizable upon request to match your application requirements.Q: What certifications are included?

A: The product is ISO9001 certified, ensuring consistent quality and manufacturing standards.Q: How is shipping handled for international orders?

A: We ship from ports like Shanghai or Tianjin, with options for inland ports, tailored to your location.Q: What is the lead time for delivery?

A: Lead times vary based on order size and customization, typically 3-6 weeks; contact us for details.Q: Is there a minimum order quantity?

A: MOQ is flexible and available upon request to accommodate different project scales.Q: How does this bar enhance safety in chemical plants?

A: Its resistance to corrosive substances reduces leak risks, ensuring safer operations and compliance with industry regulations.

Send Inquiry to This Supplier

You May Also Like

-

High-Strength Titanium Alloy Bar With Superior Corrosion Resistance for Aerospace and Medical ApplicationsNegotiableMOQ: 1 Ton

-

Welded Titanium Alloy Pipe TA3/TA4 With Mill Test Report ComplianceNegotiableMOQ: 1 Ton

-

Grade 5 Titanium Alloy Pipe TB6 for High-Pressure Chemical ProcessingNegotiableMOQ: 1 Ton

-

Precision Titanium Alloy Pipe TC6 for Medical Device ManufacturingNegotiableMOQ: 1 Ton

-

Titanium Alloy Pipe for Heat Exchanger Systems in Power PlantsNegotiableMOQ: 1 Ton

-

Cold-Rolled Titanium Alloy Pipe TA7 With 0.5mm-10mm Diameter RangeNegotiableMOQ: 1 Ton

-

High-Strength Titanium Alloy Bar With Superior Corrosion Resistance for Aerospace and Medical ApplicationsNegotiableMOQ: 1 Ton

-

Specialized TA18 Titanium Alloy Bar Manufacturer High Purity Medical Grade Titanium Rod FactoryNegotiableMOQ: 50 Kilograms

-

Precision Titanium Alloy Bar, Corrosion Resistant Titanium Alloy Bars for Marine and Chemical Processing EquipmentNegotiableMOQ: 1 Ton

-

Durable Titanium Alloy Tube for Aerospace and Medical Applications With Custom ProcessingNegotiableMOQ: 1 Ton