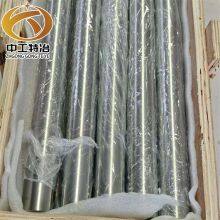

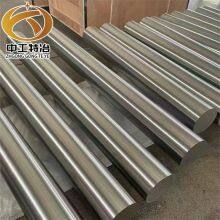

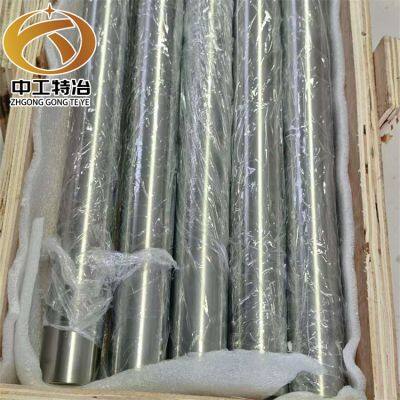

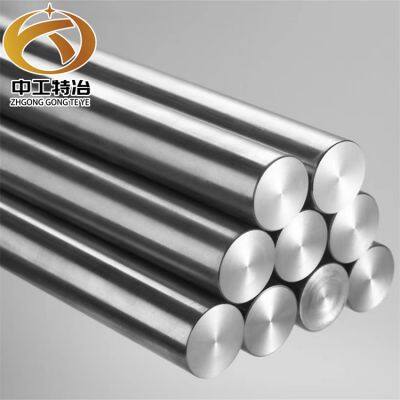

Lightweight Titanium Alloy Bar Compatible With CNC Machining Tools, Custom Sizes Available

Discover the premium Lightweight Titanium Alloy Bar engineered for seamless integration with CNC machining tools, offering exceptional strength and durability for demanding industrial applications. With custom sizes readily available, this product provides unmatched flexibility to meet specific project requirements, reducing waste and optimizing production efficiency. Backed by ISO9001 certification, it ensures consistent quality and reliability, making it an ideal choice for global buyers seeking high-performance materials. Experience the benefits of reduced machine wear and enhanced precision in your machining processes today.

This titanium alloy bar stands out for its superior corrosion resistance and high strength-to-weight ratio, enabling lighter components without compromising structural integrity. Ideal for sectors like aerospace and automotive, it delivers cost savings through extended tool life and minimized downtime. Explore how our customizable solutions can elevate your manufacturing capabilities and drive operational excellence.

Key Features and Benefits:

Lightweight Design: Reduces material handling costs and energy consumption during machining, leading to faster production cycles.

CNC Compatibility: Engineered for smooth operation with standard CNC tools, minimizing vibration and improving surface finish accuracy.

Custom Sizes: Tailor dimensions to exact specifications, including diameter, length, and tolerances, for precise fit in diverse applications.

High Corrosion Resistance: Withstands harsh environments, extending product lifespan and reducing maintenance needs in industries like marine or chemical processing.

Eco-Friendly Material: Titanium alloy is recyclable, supporting sustainable manufacturing practices and compliance with environmental standards.

Technical Specifications: Below is a summary of common parameters; all values are customizable to meet unique requirements.

| Property | Typical Range | Description |

|---|---|---|

| Material Composition | Titanium Alloy (e.g., Grade 5) | High-strength blend with elements like aluminum and vanadium for enhanced performance. |

| Diameter Options | 5mm to 200mm | Adjustable to suit various CNC setups, with tight tolerances for precision. |

| Length Range | Up to 6000mm | Custom cuts available to minimize waste and optimize logistics. |

| Weight Density | Approx. 4.5 g/cm³ | Lighter than steel, facilitating easier transport and handling. |

| Surface Finish | Smooth or machined | Options include as-drawn or polished for reduced friction in CNC operations. |

Note: All specifications can be modified based on customer input, with detailed data available upon request.

Advantages for Your Business:

Cost Efficiency: Custom sizing reduces material scrap by up to 20%, lowering overall production expenses.

Enhanced Durability: Titanium's innate properties resist wear and tear, ensuring longer component life in high-stress environments like aerospace frames or medical devices.

Global Compliance: ISO9001 certification guarantees consistent quality, facilitating easier export to markets like North America and Europe.

Versatile Applications: Suitable for prototyping, tooling, and end-use parts in industries from automotive to electronics, thanks to its adaptability.

Maximize your operational potential with our lightweight titanium alloy bars, designed to deliver precision and reliability in every CNC machining task. As a trusted supplier with ISO9001 certification and a presence in key markets worldwide, we ensure timely delivery through ports like Shanghai and Tianjin. Contact us today to discuss custom solutions tailored to your needs and unlock superior performance for your projects.

With over US$100 million in annual exports and a dedicated team, we provide expert support for all inquiries, from sample requests to bulk orders. Don't miss the opportunity to enhance your manufacturing efficiency—reach out now for a personalized quote and experience the difference quality materials make.

Frequently Asked Questions (FAQ)

Q: What makes this titanium alloy bar lightweight?

A: Titanium alloy has a high strength-to-weight ratio, typically around 4.5 g/cm³, making it lighter than many metals while maintaining robustness.Q: Can I order specific dimensions not listed in standard ranges?

A: Yes, custom sizes are fully customizable; provide your requirements, and we'll tailor the bar to your exact specifications.Q: Is this product compatible with all types of CNC machines?

A: It is designed for broad compatibility with standard CNC machining tools; consult us for specific machine models to ensure optimal fit.Q: What certifications support the quality of these bars?

A: Our products are ISO9001 certified, ensuring adherence to international quality management standards for reliability.Q: What industries commonly use this titanium alloy bar?

A: Key applications include aerospace for components, automotive for lightweight parts, medical devices for biocompatibility, and industrial machinery for durability.Q: How long does delivery take for custom orders?

A: Lead times vary but typically range from 2-4 weeks; we offer expedited options upon request to meet urgent deadlines.Q: Is there a minimum order quantity (MOQ)?

A: MOQ is flexible and can be discussed based on your project scale; contact us for details tailored to your needs.Q: How do I request a quote or place an order?

A: Reach out via our contact channels with your specifications, and our sales team will provide a prompt quote and order assistance.

Send Inquiry to This Supplier

You May Also Like

-

Grade 5 Titanium Alloy Pipe TB6 for High-Pressure Chemical ProcessingNegotiableMOQ: 1 Ton

-

Precision Titanium Alloy Pipe TC6 for Medical Device ManufacturingNegotiableMOQ: 1 Ton

-

Titanium Alloy Pipe for Heat Exchanger Systems in Power PlantsNegotiableMOQ: 1 Ton

-

Cold-Rolled Titanium Alloy Pipe TA7 With 0.5mm-10mm Diameter RangeNegotiableMOQ: 1 Ton

-

High-Strength Titanium Alloy Bar With Superior Corrosion Resistance for Aerospace and Medical ApplicationsNegotiableMOQ: 1 Ton

-

Specialized TA18 Titanium Alloy Bar Manufacturer High Purity Medical Grade Titanium Rod FactoryNegotiableMOQ: 50 Kilograms

-

Precision Titanium Alloy Bar, Corrosion Resistant Titanium Alloy Bars for Marine and Chemical Processing EquipmentNegotiableMOQ: 1 Ton

-

Durable Titanium Alloy Tube for Aerospace and Medical Applications With Custom ProcessingNegotiableMOQ: 1 Ton

-

Customizable Titanium Alloy Tube Processed to Customer Drawings With Black or Bright FinishNegotiableMOQ: 1 Ton

-

High-Strength Corrosion-Resistant Titanium Alloy Tube for Enhanced PerformanceNegotiableMOQ: 1 Ton