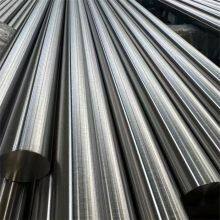

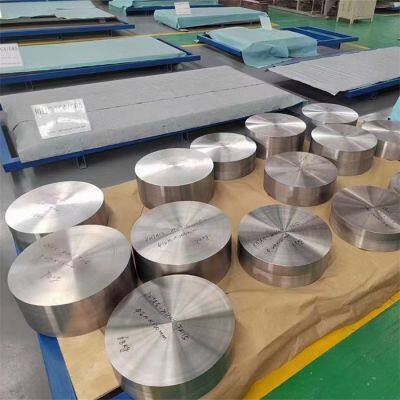

Titanium Alloy Bar Featuring Excellent Fatigue Resistance for Automotive Components and Heavy Machinery

Discover our high-performance titanium alloy bar, engineered with exceptional fatigue resistance to meet the rigorous demands of automotive components and heavy machinery applications. As a trusted distributor with extensive export experience, we deliver products that enhance durability and reliability in critical industrial settings. This bar combines lightweight strength with superior longevity, helping reduce maintenance costs and improve operational efficiency. Backed by stringent quality controls, our offerings ensure consistent performance in diverse environments, making them an ideal choice for manufacturers seeking dependable solutions.

Our titanium alloy bar stands out for its advanced properties, designed to withstand high-stress cycles and harsh conditions. Key features include:

Superior Fatigue Resistance: Engineered to endure repetitive loading without failure, extending the lifespan of components like engine parts and machinery frames.

High Strength-to-Weight Ratio: Provides significant weight savings compared to steel, enhancing fuel efficiency in vehicles and reducing energy consumption in heavy equipment.

Excellent Corrosion Resistance: Resists oxidation and chemical degradation, ideal for applications exposed to moisture, chemicals, or extreme temperatures.

Versatility in Processing: Can be easily machined, welded, or formed to custom specifications, supporting flexible manufacturing workflows.

Technical specifications highlight the bar's robust design, with parameters tailored to industry standards. Below is a summary of key attributes:

| Property | Typical Value | Details |

|---|---|---|

| Material Grade | Common Grades (e.g., Ti-6Al-4V) | Offers optimal balance of strength and ductility; other grades customizable. |

| Diameter Range | 10mm to 200mm | Suitable for various component sizes; can be adjusted per order. |

| Length | Up to 6000mm | Standard lengths available; custom cuts possible for specific needs. |

| Fatigue Strength | High, tested per ASTM standards | Ensures reliable performance under cyclic stress; data available upon inquiry. |

| Tensile Strength | Approximately 900 MPa | Provides robust structural integrity for demanding applications. |

These specifications translate into tangible benefits for clients, such as reduced downtime in automotive assembly lines and enhanced safety in heavy machinery operations. By incorporating our bar, businesses achieve cost savings through longer component life and fewer replacements. Additionally, the material's eco-friendly nature supports sustainability goals, aligning with modern industry trends. We source from reputable manufacturers and conduct rigorous inspections, ensuring every bar meets ISO9001 standards for quality assurance.

For further customization, we offer options like specific alloy compositions or surface treatments to match unique project requirements. Our global distribution network, spanning ports like Shanghai and Tianjin, enables efficient logistics to key markets including North America, Europe, and Asia. With over US$100 million in annual exports and a dedicated team, we prioritize responsive service and reliable supply chains. Explore how our titanium alloy bar can elevate your production—contact us today for a tailored quote or sample evaluation.

FAQ Section:

Q: What makes this titanium alloy bar suitable for fatigue resistance?

A: The bar is engineered with specific alloy compositions that enhance endurance under repetitive stress, making it ideal for high-cycle applications like automotive suspensions or machinery joints.Q: Can I order custom sizes for my automotive components?

A: Yes, we provide customizable dimensions, including diameter and length, to fit precise design specifications; simply share your requirements during inquiry.Q: Is the product certified for international use?

A: Absolutely, our bars are ISO9001 certified, ensuring compliance with global quality standards for reliability in diverse markets.Q: How does the fatigue resistance benefit heavy machinery applications?

A: It reduces the risk of failure in high-stress environments, leading to longer equipment life, lower maintenance costs, and improved operational safety.Q: What are the shipping options from your ports?

A: We ship from Shanghai, Tianjin, and inland ports, with flexible logistics to destinations worldwide; delivery times and costs depend on order specifics.Q: Are samples available for testing?

A: Yes, samples can be provided upon request to verify performance and suitability before bulk orders.Q: What is the typical lead time for orders?

A: Lead times vary but are optimized for efficiency; standard orders may ship in 2-4 weeks, while custom items take longer based on complexity.

Send Inquiry to This Supplier

You May Also Like

-

Custom-Cut Titanium Alloy Pipe With Full Dimensional Inspection ReportNegotiableMOQ: 1 Ton

-

High-Strength Titanium Alloy Bar With Superior Corrosion Resistance for Aerospace and Medical ApplicationsNegotiableMOQ: 1 Ton

-

Welded Titanium Alloy Pipe TA3/TA4 With Mill Test Report ComplianceNegotiableMOQ: 1 Ton

-

Grade 5 Titanium Alloy Pipe TB6 for High-Pressure Chemical ProcessingNegotiableMOQ: 1 Ton

-

Precision Titanium Alloy Pipe TC6 for Medical Device ManufacturingNegotiableMOQ: 1 Ton

-

Titanium Alloy Pipe for Heat Exchanger Systems in Power PlantsNegotiableMOQ: 1 Ton

-

Cold-Rolled Titanium Alloy Pipe TA7 With 0.5mm-10mm Diameter RangeNegotiableMOQ: 1 Ton

-

High-Strength Titanium Alloy Bar With Superior Corrosion Resistance for Aerospace and Medical ApplicationsNegotiableMOQ: 1 Ton

-

Specialized TA18 Titanium Alloy Bar Manufacturer High Purity Medical Grade Titanium Rod FactoryNegotiableMOQ: 50 Kilograms

-

Precision Titanium Alloy Bar, Corrosion Resistant Titanium Alloy Bars for Marine and Chemical Processing EquipmentNegotiableMOQ: 1 Ton