About us

Though the company has only been established for one year, it boasts over 19 years of experience deeply engaged in the water treatment sector. Its product portfolio covers a complete range of water treatment and heat exchange equipment, including constant pressure water supply devices, bladder-type automatic water supply and pressure stabilizing devices, diaphragm-type pressure tanks, plate heat exchangers, plate heat exchange units, full-automatic water softeners, and full-automatic chemical dosing devices, all backed by mature technologies.

Principle of fully automatic dosing device

1. The system meters and adds reagents through the mechanical pulsation and stroke adjustment principle of theing pump.

2. Time control mode: The metering pump and blowdown valve are controlled by a microcomputer time switch to achieve timed dosing and timeddown.

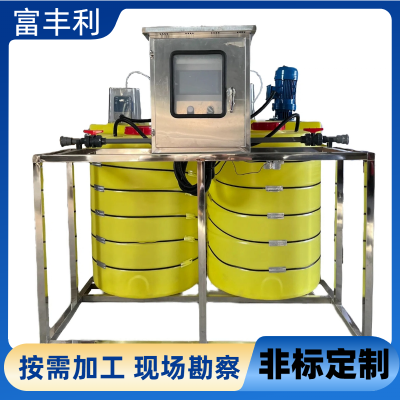

The dosing device is a metering pump as the main dosing equipment, and the dissolving medicine box, agitator, liquid level gauge, safety valve, check valve, pressure gauge, filter, buffer, pipeline, valve, base, escalator, automatic monitoring system, power control system, etc. are assembled on a public platform according to the process needs to form a module, the so-called skid-mounted combined unit (referred to as the "skid body"). According to the needs, a quantitative amount of medicine is put into the stirring solution tank for stirring and dissolving. After dissolving, it is sent to the dosing point through the metering pump. The size of the dosage can be adjusted freely to meet the needs of different dosage places.

The complete set of equipment mainly includes a feeding system, a storage barrel, a dosing system, a power control system, etc. The dissolving barrel is equipped with a liquid level gauge, a low level alarm, a valve, and other facilities required for automatic operation. The outer wall of the barrel is equipped with a magnetic copy liquid level gauge to observe the liquid level in the barrel in real time. There is an inlet on the barrel body, a spare port, and a discharge port, a sewage outlet, an overflow port, a liquid level gauge interface and corresponding supporting valves on the side of the barrel body. When the liquid level in the barrel is less than the set low liquid level value, the alarm system is automatically turned on, and the dosing pump is suspended.

How to choose the dosing device model?

The dosing device is suitable for industrial cooling circulating water systems, air conditioning and refrigeration systems, heat exchange systems, hot water boiler systems, production, domestic hot water supply systems, and other fields, so pay more attention when purchasing.

1. When users choose a dosing device, they first determine the selection specifications according to the amount of solution required by the system (including metering pump parameters, solution tank volume, etc.), and then determine the dosing method according to the dosing situation (generally using the "one use and one preparation" method).

2. Select the material of each component of the dosing device (stainless steel, carbon steel, non-metallic materials), metering pump model (diaphragm pump, plunger pump), or provide our company with the parameters of the dosing agent (name, concentration, temperature, density, viscosity, corrosiveness, etc.).

Send Inquiry to This Supplier

You May Also Like

-

Fufengli Hydraulic Module & Integrated Water Protection Unit – Constant Pressure Water Make-up Device (Maintenance and Repair)NegotiableMOQ: 1 Combo

-

Plate Heat Exchanger & Heat Exchanger Unit – Intelligent Control, Stable Performance, Direct ManufacturerNegotiableMOQ: 1 Combo

-

Plate Heat Exchanger Unit | Direct Manufacturer | Heat Exchange Station | Central Heating Equipment | Customized Design AvailableNegotiableMOQ: 1 Combo

-

Fufengli Full-Automatic Constant Pressure Water Make-up & Vacuum Degassing Device – Pressure Stabilizing Tank, Vacuum Degasser, Integrated EquipmentNegotiableMOQ: 1 Combo

-

Fufengli Large-flow Carbon Steel Manifold – Compatible With Central Air Conditioning Air-cooled Modular Units | Durable & High-qualityNegotiableMOQ: 1 Combo

-

Fufengli High-frequency Electronic Water Treatment Instrument – Customized for Water-cooled Central Air Conditioning Circulating Water SystemNegotiableMOQ: 1 Combo

-

Fufengli Full-automatic Boiler Room Water Softening Equipment – FRP Water Softener, Automatic Regeneration & BackwashingNegotiableMOQ: 1 Combo

-

Fufengli Full-process Integrated Water Treatment Device – Corrosion & Scale Prevention | for Industrial Cooling Circulating Water SystemsNegotiableMOQ: 1 Combo

-

Fufengli Capacitive Adsorption Side-stream Water Processor – Sterilization & Algae Removal | for Refrigeration Circulating Water SystemsNegotiableMOQ: 1 Combo

-

Jinchuan Non-standard Stackable Storage Cages, Convenient for Turnover, Efficient in Operation, Rust-proof and Easy to Maintain, With Standardized ManagementUS$ 75.38 - 76.92MOQ: 10 Pieces