3.Important technical parameters

MODEL | HST JBS-300B |

Type | B |

Control type | Electric |

Display type | with dial gauge and touch screen display |

Max. impact energy | 150J, 300J |

Pendulum moment 300J | 160.7695N.m |

Pendulum moment 150J | 80.3848Nm |

Min. Reading Values | 1 J |

The distance between the pendulum shaft and impact point | 750mm |

Impact speed | 5.2 m/s |

Raised angle | 150° |

Standard span | 40+0.2mm |

Round angle of the jaw | R1-1.5mm |

Round angle of impact edge | R2-2.5mm,R8±0.05mm |

Thickness of Impact Blade | 16 mm |

Angle accuracy | 0.1° |

Standard specimen dimension | 10mm×10(7.5/5)mm×55mm |

Power supply | 3 phases 4 lines, 50Hz, 380V |

Dimensions | 2124 x 600 x 1340mm |

Net Weight | 550Kg |

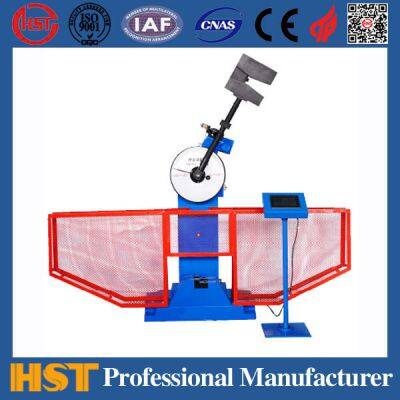

Structure and performance:

The testing machine is composed of fuselage, impact pendulum, sample support, measuring device, control mechanism and other parts

1. Fuselage: composed of a beam, Angle positioning mechanism and level.

2, impact pendulum: by an upper connecting sleeve, pendulum rod, pendulum, positioning block, impact blade, etc.

The pendulum energy consists of one main pendulum and four counterweight weights. One main pendulum is 25J. There are 4 pieces of 50J counterweight (users can choose according to their needs).

3. Sample support: composed of clamp support, clamp mouth and press block

4. Control mechanism: manual lifting hammer hanging pendulum, composed of manual and electric impact release mechanism. The mechanism is to fix the impact pendulum at a position of 150° and impact with an electric drop hammer.

5, measuring device: composed of a digital display acquisition system. The energy consumed by the sample after impact and the impact strength are shown.

6. The impact energy is calculated according to the following formula:

E=Pd (cosβ-cosα)

Where: Pd -- impact white moment (constant)

α -- measured value of pre-lifting Angle of impact pendulum (constant)

Beta -- Angle of rise after impact

50N-5KN Single Column Universal Testing Machine | Electronic Universal Testing Machine with 10kN Pneumatic Grips | Electronic Universal Testing Machine with Hydraulic grips |

Electronic Universal Testing Machine with Temperature Chamber | 50kN -1000kN Hydraulic Dynamic Static Fatigue Testing Machine | 100kN -2000kN Servo Hydraulic Universal Testing Machine |

FAQ:

Send Inquiry to This Supplier

You May Also Like

-

JB-500B 300J 500J Low Temperature Pendulum Impact Non-ferrous Metal Testing Machine Pendulum Charpy Impact Testing MachineUS$ 1100 - 3700MOQ: 1 Set

-

500J Impact Strength Testing Machine 500j Computer Pendulum Charpy Impact TesterUS$ 1100 - 3700MOQ: 1 Set

-

Astm D256 Astm D256 Iso180 Jb T8762 Izod Charpy Impact TesterUS$ 1100 - 3700MOQ: 1 Set

-

HST Impact Testing Specimen Notch Broaching Machine / Impact Sample Prepare MachineUS$ 19594.12 - 20986.71MOQ: 1 Set

-

HST VU-1S Manual Control Impact Sample Notch Broaching MachineUS$ 6997.90 - 10496.85MOQ: 1 Set

-

HST Impact Specimen Notch Manual Broaching Machine Metal Single Tool Specimen UV Notch Broaching Machine MatchingUS$ 6997.90 - 10496.85MOQ: 1 Set

-

HST Impact Specimen Notching Machine Charpy Impact Test Broaching Machine Metal Test Specimen Notching EquipmentUS$ 10496.85 - 13995.80MOQ: 1 Set

-

HST Electronic 10x10x55mm UV Notch Broaching Cutting MachineUS$ 10496.85 - 13995.80MOQ: 1 Set

-

HST Impact Sample U V Notch Broaching Machine Impact Specimen Notching Broaching MachineUS$ 10496.85 - 13995.80MOQ: 1 Set

-

DWTT 100000J ASTM E436-03 Pipeline Steel Drop Ball Impact Testing MachineUS$ 45000 - 50000MOQ: 1 Set