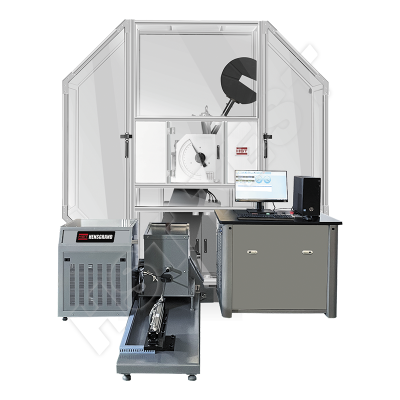

HST JBDW-750CY-80 750j Low Temperature Computer Automatic Impact Testing Machine(-80℃)

JIS Z 2242 -Method for CHARPY pendulum impact test of metallic materials.

EN 10045-1 -Metallic materials-CHARPY impact test.

ASTM E23 (CHARPY) -Standard test method for notched bar impact testing of metallic materials.

GOST 9454-78 -Impact bending test method at low, room and high temperatures.

ISO R83 Impact test of steel (CHARPY) test (U-type notch)

G 145-2007 Pendulum Impact Test Machine

3.Specifications

MODEL | HST JBDW-750CY-60/80 | |||||

Machine type | Type C | |||||

Display type | Computer and dial display | |||||

Max. impact energy | 750J | |||||

Effective test range | 10%-90%FS | |||||

Optional pendulum | 300J, 450J, 600J | |||||

Pendulum moment 150J | 80.3848Nm | |||||

Pendulum moment 300J | 150.7695 Nm | |||||

Pendulum moment 450J | 241.1543 Nm | |||||

Pendulum moment 600J | 321.5390 Nm | |||||

Pendulum moment 750J | 401.9238 Nm | |||||

The distance between the pendulum shaft and impact point | 750mm | |||||

Impact speed | 5.24 m/s | |||||

Angle resolution | 0.025° | |||||

Striking angle | 150°±1 | |||||

Support span | 40+0.2mm | |||||

Radius of support curvature | R1~1.5mm | |||||

Angle of support taper | 11±1° | |||||

Striking tip angle | 30°±1° | |||||

Striking edge radius | 2mm impact edge | 2mm-2.5mm | ||||

8mm impact edge | 8mm±0.05mm | |||||

8mm impact shoulder Angle radius | 0.1mm-1mm | |||||

8mm impact edge width | 4mm ±0.05mm | |||||

Impact blade width | 10-18mm | |||||

Striking thickness | 16 mm | |||||

Standard specimen dimension | 55×10×10mm, 55×10×7.5mm, 55×10×5mm according to customer sample size | |||||

Measured parameters | ||||||

Angle measurement | photoelectric encoder | |||||

Angle accuracy | 0.025 | |||||

Dial energy resolution | ≥0.5J | |||||

computer screen display energy resolution | 0.01J | |||||

Low temperature and sample positioning mechanism parameters | ||||||

Refrigeration mode | Compressor | |||||

Refrigerating medium | Freon | |||||

Capacity of sample box | Standard 20 | |||||

Temperature control range | +25℃~-60°c/-80°c | |||||

Constant temperature accuracy | ±0.5°C | |||||

Cooling rate | +30℃ ~ -60℃, not more than 60 minutes | |||||

Heating method | electric hot plate | |||||

Temperature control type | PID | |||||

Digital timer | 1 min -999 min, resolution 1 min | |||||

Effective work space | Cold room space: 250×56×11mm | |||||

Sample delivery method | pneumatic | |||||

Sample delivery positioning time | ≤5S | |||||

Positioning mode | pneumatic | |||||

Positioning accuracy | 0.1 mm | |||||

Pneumatic pressure | 0.6 to 0.7MPa | |||||

Angle measurement | photoelectric encoder | |||||

Machine parameter | ||||||

Dimensions | Host machine | 2220×900×2220mm | ||||

Cooling part | 1020×750×750mm | |||||

Electrical cabinet | 960×620×830mm | |||||

Weight | Host machine | Approx. 1500kg | ||||

Cryogenic system | ≈250kg | |||||

Electrical cabinet | About 100kg | |||||

Power | Main motor | 0.37 kW | ||||

refrigeration | 3 kW | |||||

Power supply | AC 380V± 10%, 50Hz | |||||

4. Features:

* Front and rear columns are symmetrical. Pendulum arm isdesigned of cantilever beam support, with simple structure and high machined precision

* Apply high precision bearing with small friction. Absorbing energy without loading is less than 0.3%

* High rigid pendulum arm prevents axial and transversevibrations

* Double reduction gear system replaces old style drivesystem with high efficiency and avoiding transmission failure

* Round pendulum head design reduces windage losses to the most.

* Exchangeable pendulum is simple to change to satisfyimpact energy of 150J,300J,450J,600J,750J

* Electromagnetic release ofpendulum hammer and electromagnetic clutch for locking the pendulum and raising it to its initial position. A damper is equipped to prevent strong bump when clutching

* Full-closed enclosure with high safety to prevent brokensample from splitting.Protective screening has interlock door.When the door opens, most operations can't work to avoid any wrong operation

* When connected to aprinter, user input information and test results will be printed. computer with software control is

available to realize semiautomatic operation. Operator only need charge Others can be controlled by software

* Optional specimen feeding system is available. Combinedwith computer and software, fully automatic operation can be realized.

* Optional cooling system is available to satisfy cold specimentest down to -180℃

different collecting box

5.Software Interface:

* Safety pin guaranties the impact action, standard protection shell to avoid any accident.

* Pendulum will automatically rising and ready for next impact action after specimen breakout.

* PC software to display the energy loss, impact tenacity, rising angle, test average value etc. test data and result, also the

curve display available, with calculation and report printing function. The dial scale can show test results too

50N-5KN Single Column Universal Testing Machine | Electronic Universal Testing Machine with 10kN Pneumatic Grips | Electronic Universal Testing Machine with Hydraulic grips |

Electronic Universal Testing Machine with Temperature Chamber | 50kN -1000kN Hydraulic Dynamic Static Fatigue Testing Machine | 100kN -2000kN Servo Hydraulic Universal Testing Machine |

Send Inquiry to This Supplier

You May Also Like

-

Astm D256 Astm D256 Iso180 Jb T8762 Izod Charpy Impact TesterUS$ 1100 - 3700MOQ: 1 Set

-

HST Impact Testing Specimen Notch Broaching Machine / Impact Sample Prepare MachineUS$ 19594.12 - 20986.71MOQ: 1 Set

-

HST VU-1S Manual Control Impact Sample Notch Broaching MachineUS$ 6997.90 - 10496.85MOQ: 1 Set

-

HST Impact Specimen Notch Manual Broaching Machine Metal Single Tool Specimen UV Notch Broaching Machine MatchingUS$ 6997.90 - 10496.85MOQ: 1 Set

-

HST Impact Specimen Notching Machine Charpy Impact Test Broaching Machine Metal Test Specimen Notching EquipmentUS$ 10496.85 - 13995.80MOQ: 1 Set

-

HST Electronic 10x10x55mm UV Notch Broaching Cutting MachineUS$ 10496.85 - 13995.80MOQ: 1 Set

-

HST Impact Sample U V Notch Broaching Machine Impact Specimen Notching Broaching MachineUS$ 10496.85 - 13995.80MOQ: 1 Set

-

DWTT 100000J ASTM E436-03 Pipeline Steel Drop Ball Impact Testing MachineUS$ 45000 - 50000MOQ: 1 Set

-

ASTM E208 5000J 80000J 1000kj Drop Weight Tear TesterUS$ 75000 - 80000MOQ: 1 Set

-

ASTM E23 450J, 500J 750J Charpy Izod Low-temperature Automatic Impact Testing Machine TesterUS$ 9400 - 9800MOQ: 1 Set