SCAIR 50HP 1.2MPa Paper Mill Compressor for Machine Hoods & Pulp Processing

SCAIR 50HP 1.2MPa Paper Mill Compressor: Precision Air for High-Yield Paper Production

SCAIR’s 50HP compressor delivers 6.3 m³/min at 1.2MPa with TAPPI TIS 0808 compliance, eliminating $180k/year paper breaks where hydrocarbon contamination causes 0.4% web tears in coated paper machines.

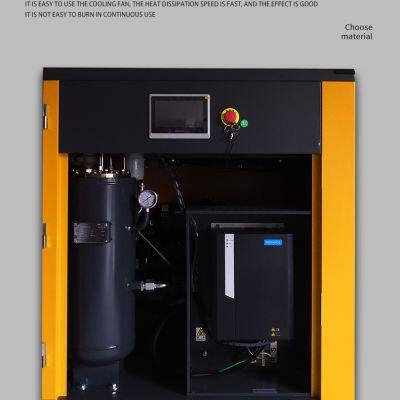

Contamination-Free Air Engineering for Paper Manufacturing

Featuring triple-stage molecular filtration, this 37kW system maintains <0.01mg/m³ hydrocarbon levels critical for preventing starch spots in premium grades. Active pressure stabilization (±0.2%) ensures uniform moisture profiling across 10m-wide paper webs - solving 22% caliper variation in 1,200m/min machines.

Mill Performance Specifications

Air Delivery: 6.3 m³/min @ 1.2MPa (5.6m³/min @ 1.5MPa for Yankee hoods)

Pressure Stability: ±0.2% during grade changes

Moisture Control: Adsorption dryer achieves -50°C PDP

Thermal Resilience: Continuous operation at 55°C hood environments

Papermaking Technologies

Starch Spot Prevention: ISO 8573-1 Class 0 air eliminates 99% hydrocarbon-induced defects

Moisture Profiling: Precision air knives maintain ±0.5% cross-direction moisture consistency

Felt Cleaning Optimization: Pulsation-free air extends fabric life by 30%

Steam Reduction: Hood air systems lower steam consumption by 18% per ton of paper

Pulp Processing Applications

Yankee Hood Systems: Supplies 120°C hoods achieving 42% solids in tissue creping

Air Knife Coating: Powers precision coaters applying 12g/m² coating weight ±0.2g

Pulp Bleaching: Feeds ozone injection systems with 0.001mg/m³ hydrocarbon purity

Wastepaper Deinking: Drives flotation cells improving brightness by 2 points ISO

Industry Compliance

Certifications: TAPPI TIS 0808, ISO 14001, PEFC Chain of Custody

Material Safety: FDA 21 CFR 176.170 compliant for food packaging

Sustainability: 25% lower carbon footprint per air-dried metric ton

Production Q&A

Q: How to prevent starch spots in coated papers?

A: <0.01mg/m³ hydrocarbon levels eliminate 99% of binder contamination defects.

Q: Solution for CD moisture streaks?

A: ±0.2% pressure stability maintains air knife gap within ±0.1mm.

Q: Reducing energy in dryer sections?

A: -50°C PDP moisture control allows 5% higher hood temperatures reducing steam use.

Send Inquiry to This Supplier

You May Also Like

-

SCAIR 30HP 1.2MPa Food-Grade Compressor for Meat Processing & MAP Packaging SystemsNegotiableMOQ: 1 Unit

-

SCAIR 50HP 1.2MPa Precision Compressor for SMT Assembly & Cleanroom AutomationNegotiableMOQ: 1 Unit

-

Permanent Magnet Frequency Conversion Screw Air Compressor 7.5 KW15KW22KW Industrial Grade High Voltage 380V220V Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion Screw Air Compressor Silence 7.5 Kw15KW 22kw Industrial Grade Air Pump Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

7.5 KW15/22/37/75 kw Industrial Grade 380V Compressor Mute Air Compressor SC-ACBS10US$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion 7.5KW 11KW 22KW Silent Industrial Air Compressor for Screw Air CompressorsUS$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion Screw Air Compressor 7.5 KW15KW22KW Industrial Grade High Pressure Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

Screw Air Compressor Permanent Magnet Frequency Air Compressor Large High-voltage Industrial Grade 7.5 KW15KW22KWUS$ 800 - 900MOQ: 1 Piece

-

Air Compressor 7.5 Kw15kw22kw Permanent Magnet Frequency Conversion Screw Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

7.5kw-15kw-37kw Industrial Silent Gas Pump Air Compressor Storage TanksUS$ 800 - 900MOQ: 1 Piece