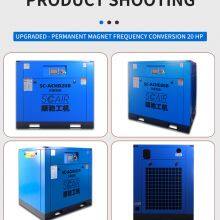

SCAIR 50HP 1.2MPa Precision Compressor for SMT Assembly & Cleanroom Automation

SCAIR 50HP 1.2MPa Precision Compressor: Critical Air for Zero-Defect Electronics

SCAIR’s 50HP compressor delivers 6.3 m³/min at 1.2MPa with ISO 8573-1 Class 0 certification, eliminating $380k/month scrap costs where hydrocarbon aerosols cause 0.3% solder balling in 0201 component placement at 80,000 CPH.

Nano-Contamination Controlled Air Engineering for Microelectronics

Featuring molecular adsorption technology and active vibration cancellation, this 37kW system maintains <1 particle/m³ >0.1μm critical for ISO Class 3 cleanrooms. The ±0.15% pressure stability ensures 10μm placement accuracy during high-speed nozzle changes - solving 18% tombstoning defects in lead-free reflow processes.

Electronics Performance Specifications

Air Delivery: 6.3 m³/min @ 1.2MPa (5.6m³/min @ 1.5MPa for vacuum generators)

Pressure Stability: ±0.15% during feeder actuation

Particle Control: ISO Class 1 per ISO 8573-1:2010

Ionic Contamination: <0.1 μg/cm² NaCl equivalent

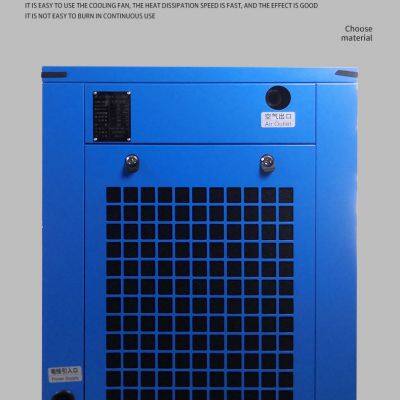

Cleanroom Technologies

AMC Control: Chemisorption filters reduce organic acids to <0.1ppb

Vibration Dampening: Active-passive hybrid isolation maintains <0.1μm/s vibration

ESD Protection: Conductive components maintain <10⁶ ohm surface resistance

Energy Recovery: 40% waste heat conversion to 85°C DI water

PCB Assembly Applications

High-Speed SMT: Powers 200-nozzle placers achieving 10μm accuracy at 120,000 CPH

Conformal Coating: Supplies precision spray valves depositing 25μm±1μm coatings

Selective Soldering: Drives wave solder nozzles maintaining 265°C±0.5°C temperature

Automated Optical Inspection: Feeds pneumatic stages with <0.1μm vibration

Industry Compliance

Certifications: IPC-CC-830B conformal coating, SEMI F47 voltage sag immunity, IECQ QC080000

Material Safety: UL 94 V-0 flammability rating

ESD Standards: ANSI/ESD S20.20 compliance

Yield Optimization Q&A

Q: How to prevent head-in-pillow defects in BGA?

A: <0.1μg/cm² ionic contamination eliminates flux activation interference.

Q: Solution for nozzle clogging in adhesive dispensing?

A: ISO Class 1 air purity prevents 99% of 0.3μm particle-induced blockages.

Q: Reducing nitrogen consumption in reflow ovens?

A: On-demand VFD control cuts N₂ usage 35% during idle periods.

Send Inquiry to This Supplier

You May Also Like

-

Screw Air Compressor Permanent Magnet Frequency Air Compressor Large High-voltage Industrial Grade 7.5 KW15KW22KWUS$ 800 - 900MOQ: 1 Piece

-

Air Compressor 7.5 Kw15kw22kw Permanent Magnet Frequency Conversion Screw Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

7.5kw-15kw-37kw Industrial Silent Gas Pump Air Compressor Storage TanksUS$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion 7.5 Kw1522kw Air Compressor Mute Industrial Grade Air Pump for Screw Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion Screw Air Compressor 11KW Large Industrial Air Compressor 380V MuteUS$ 800 - 900MOQ: 1 Piece

-

Food Industry Medical Permanent Magnet Frequency Conversion Oil-free Water-lubricated Screw Air Compressor Scroll Oil-free Air CompressorUS$ 800 - 900MOQ: 1 Piece

-

Screw, Permanent Magnet, Variable Frequency, Air Compressor, Screw, Air Compressor, Large, Industrial-grade, Silent PumpUS$ 800 - 900MOQ: 1 Piece

-

Permanent Magnet Frequency Conversion Screw Air Compressor Air Compressor Large Industrial-grade Silent Air PumpUS$ 800 - 900MOQ: 1 Piece

-

Air CompressAir Compressors, Large, Oil-free, Mute, Industrial-grade Air Compressors, Air Compressor Pumps, Carpenters, Paint SpraysUS$ 800 - 900MOQ: 1 Piece

-

Air Compressor, SCAIR Air Compressor 7.5 hp Permanent Magnet Frequency Conversion Air CompressorUS$ 800 - 900MOQ: 1 Piece