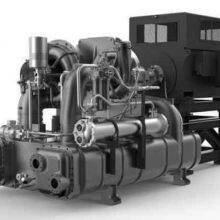

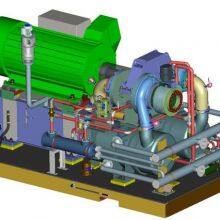

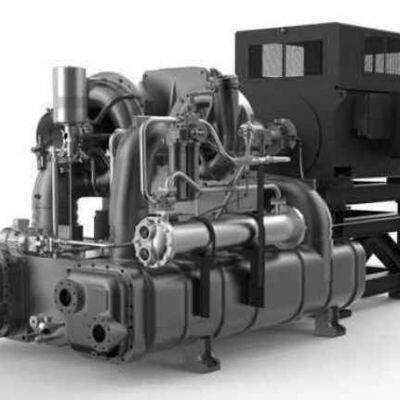

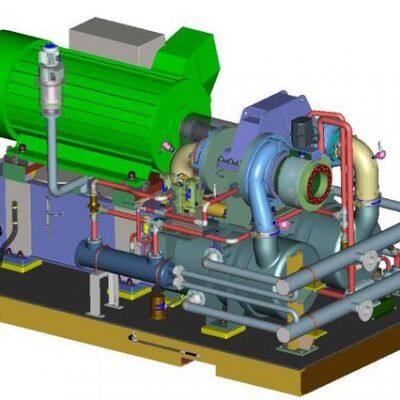

Centrifugal Compressor Turbine Compressor Circulating Supercharger Nitrogen Compression and Expansion Machine

Confirmation of Medium Characteristics (directly determines material and structure)

Medium types: Air, natural gas, syngas (H₂/CO), steam, corrosive gases (e.g., chlorine, ammonia), etc.;

Key properties:

Flow and Pressure Parameters (Core Performance Indicators)

Flow requirement: Clearly specify standard condition flow rate (Nm³/h, 0℃/101.3kPa) or operating condition flow rate (m³/h, actual inlet temperature/pressure), with deviation ≤ ±5% (to avoid overload or capacity waste);

Pressure requirement:

Operating Condition Fluctuation Range

Flow adjustment range: Conventional units adapt to 30%~110% of rated flow rate (select frequency conversion or inlet guide vane adjustment for high variable condition demand);

Inlet condition fluctuation: Temperature (±10℃), pressure (±5%); confirm whether temperature-resistant/high-pressure-resistant design is required (e.g., inlet temperature ≤ 80℃, add cooler if exceeding the limit).

Efficiency Indicators

Isothermal efficiency: ≥75% for air compressors, ≥70% for process gas compressors (per API 617 standard, each 1% increase in efficiency reduces annual energy consumption by approximately 2%);

Specific power (shaft power/standard condition flow rate, kW·h/Nm³): The smaller the value, the more energy-efficient; ≤0.085kW·h/Nm³ for air compressors (at 0.7MPa pressure).

Adaptation of Adjustment Methods

Stable operating conditions: Select inlet guide vane adjustment (adjustment range 50%~100%, low energy consumption);

Significant variable operating conditions: Select frequency conversion adjustment (adjustment range 20%~100%, energy saving rate 20%~40%);

Emergency conditions: Anti-surge protection is required (surge line must be far from normal operating point, reserve 15%~20% safety margin).

Continuous Operation Capability

Design life: ≥20 years, service life of wearing parts (e.g., bearings, seals) ≥8000 hours;

Standby configuration: Critical processes (e.g., petrochemical cracked gas compression) require 1 active + 1 standby unit, or parallel dual units (to ensure uninterrupted gas supply).

Sealing Performance

Zero-leakage requirement (e.g., food, pharmaceutical, toxic gases): Select dry gas seal (leakage ≤1Nm³/h);

General operating conditions: Select labyrinth seal (low cost, suitable for non-toxic media such as air and steam).

Installation Conditions

Space dimensions: Reserve maintenance space (≥1.5m around the unit, ≥2.5m above the unit for impeller and bearing replacement);

Foundation load: Design based on total unit weight (including auxiliary equipment), dynamic load coefficient ≥1.2 (to avoid vibration transmission).

Cooling and Noise Reduction

Cooling method: Water cooling (inlet water temperature ≤32℃, water pressure 0.2~0.4MPa) or air cooling (ambient temperature ≤40℃, wind speed ≥2m/s);

Noise control: Unit operating noise ≤85dB(A) (at 1m distance); add sound insulation cover or silencer if exceeding the standard.

Industry standards: Must comply with API 617 (Centrifugal Compressors for Petroleum, Chemical, and Gas Industry Services), GB/T 13275 (Centrifugal Fans for General Purposes), ASME BPVC (Boiler and Pressure Vessel Code);

Environmental requirements: Lubricating oil must comply with ISO VG 46/68 standard, waste oil discharge ≤5mg/L (to avoid medium or environmental pollution).

Parameter Name | Definition and Unit | Conventional Range | Selection Key Points |

Standard Condition Flow Rate (Qₙ) | Gas volume flow rate under standard conditions | 100~100,000 Nm³/h | Must match process gas consumption, reserve 10%~15% margin |

Rated Discharge Pressure (P) | Outlet absolute pressure | 0.3~10 MPa (single-stage ≤4MPa) | Include pipeline loss, avoid "over-capacity operation" |

Compression Ratio (ε) | Discharge pressure/inlet pressure | 1.5~4 (single-stage), ≤10 (multi-stage) | Ultra-high pressure (>10MPa) requires 2~3 series-connected units |

Isothermal Efficiency (ηₜ) | Theoretical isothermal power/actual shaft power | ≥75% (air compressors), ≥70% (process compressors) | Each 5% decrease in efficiency increases annual energy consumption by ~10% |

Shaft Power (Pₛ) | Power required to drive the compressor | 50~10,000 kW | Match motor power (motor power = shaft power/transmission efficiency) |

Surge Flow Rate (Qₛᵤᵣ) | Minimum flow rate causing surge | 30%~50% of rated flow rate | Normal operating flow rate ≥1.2×surge flow rate |

Parameter Name | Common Specifications | Selection Adaptation Suggestions |

Impeller Stages | 1~10 stages (single-cylinder ≤6 stages) | Select single-stage for compression ratio ≤4, multi-stage for 4~10 (evenly distribute compression ratio per stage) |

Impeller Material | Carbon steel (Q345R), stainless steel (304/316), Hastelloy | Carbon steel for air/steam, Hastelloy for corrosive gases |

Shaft Seal Type | Labyrinth seal, dry gas seal, mechanical seal | Labyrinth seal for non-toxic media, dry gas seal for toxic/high-pressure media |

Cooling Method | Water cooling (shell-and-tube), air cooling (finned) | Water cooling for large units (power ≥500kW), air cooling for small units |

Drive Method | Motor drive, steam turbine drive | Motor drive for stable power grid, steam turbine drive for steam source (energy-saving) |

Adjustment Mechanism | Inlet guide vane, frequency conversion, return valve | Frequency conversion for variable conditions ≤50%, inlet guide vane for 50%~100% |

Parameter Name | Normal Range | Alarm Threshold | Abnormal Cause Analysis |

Discharge Temperature | ≤120℃ (air compressors), ≤150℃ (process compressors) | >130℃ (air compressors) | Cooling system failure, excessive compression ratio |

Bearing Temperature | Rolling bearing ≤80℃, sliding bearing ≤70℃ | Rolling bearing >90℃, sliding bearing >80℃ | Insufficient lubrication, bearing wear |

Shaft Vibration Value | ≤4.5 mm/s (RMS) | >6.3 mm/s | Impeller imbalance, coupling misalignment |

Seal Gas Pressure | 0.1~0.2MPa higher than discharge pressure | Deviation >±0.05MPa | Seal gas system leakage, pressure reducing valve failure |

Lubricating Oil Pressure | 0.2~0.4MPa | <0.15MPa | Oil pump failure, oil circuit blockage |

Application Industry | Medium Type | Standard Condition Flow Rate (Nm³/h) | Rated Discharge Pressure (MPa) | Compression Ratio | Key Configuration Requirements |

Petrochemical Industry (Catalytic Cracking) | Cracked Gas (C₂/C₃) | 5000~20,000 | 2.5~4.0 | 6~8 | Multi-stage compression + dry gas seal + anti-surge system, material: 316L |

Natural Gas Transmission | Natural Gas (CH₄) | 10,000~50,000 | 4.0~8.0 | 8~10 | High-pressure resistant impeller + frequency conversion adjustment, adapt to pressure fluctuations |

Power Industry (Gas Turbine) | Compressed Air | 20,000~80,000 | 0.6~1.0 | 1.8~3 | Single-stage/multi-stage + water cooling, isothermal efficiency ≥78% |

Chemical Industry (Ammonia Synthesis) | Syngas (H₂/N₂) | 3000~15,000 | 3.0~5.0 | 7~9 | Optimized impeller for low-molecular-weight gas + explosion-proof motor |

Metallurgical Industry (Blast Furnace Blowing) | Air | 50,000~100,000 | 0.3~0.5 | 1.5~2 | Dual-cylinder parallel connection + inlet guide vane adjustment, dust-resistant design |

Avoid "Flow/Pressure Overload": Actual operating flow rate shall not exceed 110% of rated flow rate, and pressure shall not exceed 105% of rated pressure; otherwise, impeller fatigue damage may easily occur;

Do Not Ignore Medium Composition: For example, natural gas containing H₂S requires sulfur-resistant materials (e.g., SS 316L); hydrogen content ≥50% requires adjusting impeller speed (to avoid supersonic flow);

Anti-Surge Protection Must Be In Place: Set surge alarm and automatic return valve in the control system to prevent the unit from entering the surge region due to sudden flow drop;

Prioritize Energy Efficiency Over Initial Cost: High-efficiency units (isothermal efficiency ≥75%) have 10%~15% higher initial investment but can reduce annual energy consumption by 15%~20%, with cost recovery in 3~5 years;

Synchronize Selection of Supporting Systems: Confirm parameter matching of cooling system (water volume/water temperature), lubricating oil system (oil brand/replacement cycle), and filtration system (precision/pressure difference) simultaneously.

Send Inquiry to This Supplier

You May Also Like

-

Medium and High Pressure Oil-free Gas Booster Nitrogen CompressorUS$ 2000 - 3000MOQ: 1 Combo

-

Screw CompressUS$ 5000MOQ: 1 Unit

-

WOODWARD 8200-1301 505 Digital Speed Regulator: Real-World Stability for Turbine & Compressor ControlNegotiableMOQ: 1 Bag

-

SCAIR 75HP 1.2MPa Power Plant Compressor for Turbine Control & Ash Handling SystemsNegotiableMOQ: 1 Unit

-

Weichai 1001319530 Tensioning Mechanism Vp12 611600060025 ROLLER TENSIONER 1002149621 VIDEO CLIP 1000428205 Oil Filter 1002015703 Turbine Vp7 610800030073 Connecting Rod 1002109228 Connecting Rod Insert Vp7 1002048716 Compressor Vp12NegotiableMOQ: 1 Bag

-

Vacuum Compressor Stainless Steel Impeller, Turbine Blade and Turbine ImpellerUS$ 0.1 - 10MOQ: 10 Pieces

-

Machine of Compressor Part Impeller Turbine 5 Axis Machine CenterUS$ 1 - 50MOQ: 1 Piece

-

Centrifugal Compressor Turbine Compressor Circulating Supercharger Nitrogen Compression and Expansion MachineNegotiableMOQ: 1 Unit

-

Electric Turbine CompressorsUS$ 100 - 880MOQ: 10 Sets

-

Industrial Air Compressor Steam Turbine CompressorUS$ 1,600 - 1,600MOQ: 1 Unit