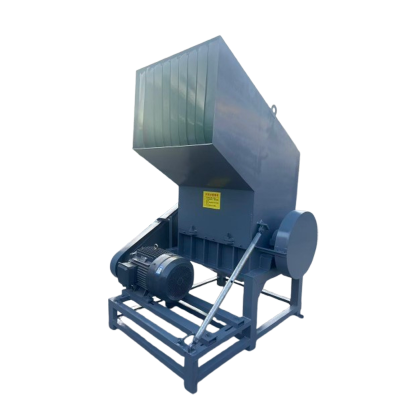

Industrial Plastic Granulator Crusher Machine for Plastic Pipes Sheets Bottles Waste Recycling

Revolutionize your plastic recycling operations with our Industrial Plastic Granulator Crusher Machine - engineered to process pipes, sheets, bottles and mixed plastic waste with exceptional efficiency.

This robust recycling solution transforms bulky plastic scrap into uniform granules ready for reprocessing, featuring heavy-duty construction and intelligent safety mechanisms. Engineered for continuous industrial operation, it delivers substantial cost savings through reduced material handling expenses and optimized raw material reuse.

Core Advantages:

- Precision Cutting System - Interlocking rotary blades maintain sharpness 3x longer than standard crushers

- Adaptive Processing - Automatically adjusts torque for varying material thickness (1-40mm)

- Reduced Maintenance - Sealed bearing units with grease reservoirs extend service intervals

- Dust Suppression - Integrated air flow channels minimize particulate dispersion

Technical Specifications:

| Model | PG-300 | PG-600 | PG-1500 |

|---|---|---|---|

| Throughput Capacity | 300 kg/h | 750 kg/h | 1500 kg/h |

| Motor Power | 15 kW | 30 kW | 55 kW |

| Hopper Size | 800×600mm | 1200×800mm | 1500×1000mm |

| Granule Size | 5-12mm | 5-12mm | 8-15mm |

Operational Benefits:

- 40% energy reduction vs. comparable crushers through optimized blade geometry

- Tool-free screen replacement in under 15 minutes

- Vibration-dampening mounts allow installation without special foundations

- Reversible cutting edges double blade service life

Industry Applications:

- Plastic Pipe Manufacturers - Recycle production scrap and off-spec products

- Recycling Facilities - Process municipal collection streams and industrial waste

- Packaging Plants - Granulate bottles, containers and thermoformed packaging

- Automotive Suppliers - Reclaim bumper, trim and interior component scrap

Discover how our granulators can increase your material recovery rates while reducing disposal costs - request throughput test reports for your specific material mix. All critical components carry 18-month warranty coverage with expedited spare parts delivery from our 30,000m² manufacturing facility.

Frequently Asked Questions:

Q: What plastic types can this machine process?

A: Processes PP, PE, PVC, ABS, PS and most engineering plastics excluding PTFE.

Q: How often do blades require replacement?

A: Typical blade life is 400-600 operating hours depending on material abrasiveness.

Q: Is the control system waterproof?

A: Control cabinet meets IP54 rating for dust and water splash resistance.

Q: Can it handle plastic with metal contaminants?

A: Standard models require metal-free input; optional metal detection available.

Q: What maintenance is required?

A: Weekly inspection of blades and monthly bearing lubrication (grease provided).

Q: Is installation support available?

A: Comprehensive installation manuals provided; technician dispatch optional.

Send Inquiry to This Supplier

You May Also Like

-

China High Quality Plastic Crusher EquipmentUS$ 1800MOQ: 1 Set

-

Professional Plastic Crusher ManufacturerUS$ 1800MOQ: 1 Set

-

China Plastic Crusher Professional FactoryUS$ 1800MOQ: 1 Combo

-

Double Shaft Industrial Shredder Machine Waste Plastic Shredder Scrap Car Tire Shredder for Waste Recycling Tire Recycling PlantUS$ 2460 - 3514MOQ: 1 Set

-

Made in China Plastic Lumps Shredder Double Shaft Plastic Crusher Machine Plastic Bucket Drum Bucket Cask CrushingUS$ 2460 - 12096MOQ: 1 Set

-

Small Copper Wire Separator, Miscellaneous Wire Copper Plastic Separator, Dry Copper Wire SeparatorUS$ 5200.00MOQ: 1 Cubic Meter

-

Copper Wire Recycling and Sorting Machine Dry Copper Wire Recycling Machine Miscellaneous Wire Copper Wire Recycling MachineUS$ 5000.00MOQ: 1 Cubic Meter

-

Fully Automatic Dry Copper Wire Separation Machine, Waste Cable and Wire Separation EquipmentUS$ 4400.00MOQ: 1 Cubic Meter

-

Plastic Recycling Machine Shredder Machine Straw Grinding Machine Paddy Straw Shredder Coconut Shredder MachineUS$ 2600 - 12096MOQ: 1 Set

-

Fully Automatic Copper Wire Separation Machine Equipment Small Wire Separation and Copper Extraction MachineUS$ 4400.00MOQ: 1 Ton