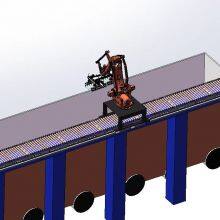

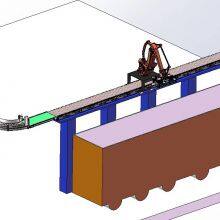

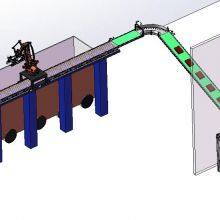

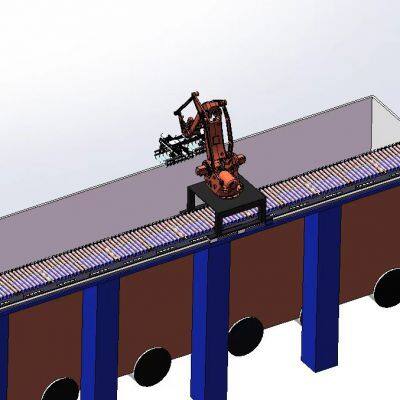

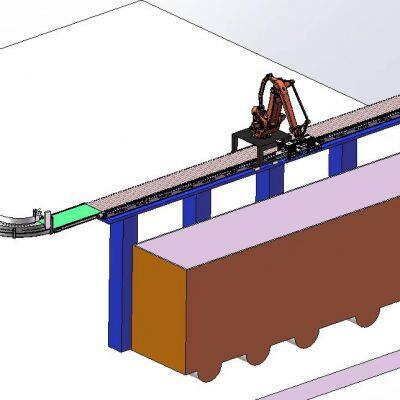

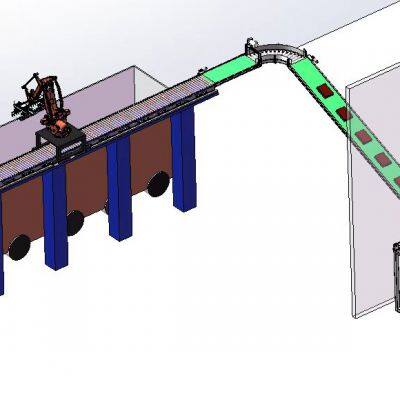

Fully Automatic Truck Loading Robot Six-Axis Bagged Compound Fertilizer Robotic Arm, Composite Loading Robot 1200-1400 Bags per Hour

Fully automatic truck loading robot Six-Axis Bagged Compound Fertilizer Robotic Arm, Composite Loading Robot 1200-1400 bags per hour

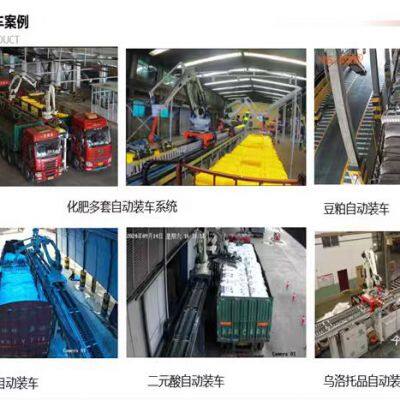

1. E-commerce warehousing: Automatically grasping and stacking packages at express delivery sorting centers improves order outbound loading efficiency

2. Manufacturing: Connecting to production lines, precisely loading finished parts and finished products onto transport pallets or trucks

3. Cold chain logistics: Loading frozen and fresh produce in low-temperature environments (e.g., -20°C cold storage),

1. High Efficiency: 24/7 continuous operation with a stable loading speed far exceeding the daily workload of manual workers

2. Strong Safety: Replacing manual labor with high-risk (toxic, corrosive) and high-intensity environments, reducing the risk of workplace injuries

3. Accurate Precision: Sensors and algorithmic control minimize cargo positioning errors, reducing damage from stack collapse and collisions

2. Path Planning: The system automatically plans the robotic arm's grabbing and stacking paths based on the truck compartment space and cargo placement rules.

3. Grasping and Loading: The robotic arm accurately grabs cargo according to the planned path and smoothly transfers it to the designated area on the truck compartment for stacking.

4. Verification and Closing: After loading is complete, sensors check the stability of the cargo stacking, generate a loading list, and provide feedback to the management system.

automatic grade | Automatic |

voltage | 380V |

machinery capacity | 1000 |

key machines | loader |

packaging material | bag |

Weight (KG) | 2000 |

product name | Fully automatic loading and unloading truck bag loader |

Rotary stacking is mainly used in beer, beverage, medicine and other industries production line back end stacking, with more than

180 degrees of rotation function, can be applied to multiple pallets stacking at the same time, flexible rotation, small area,

there are many dimensions, performance can be compared to robot stackingIntegrated solution packaging solution, cost effective reduction

The compact arrangement is simpler than the bus-type wiring.

Close to the control core, the communication is faster than the bus type.

Faster connection, more accurate dynamic compensation.

With rich palletizing scenarios, it can be quickly replicated.

Design a guided palletizing process setting interface, which is easy to use.

Provide palletizing instruction library, support customized development, easy to match with interface equipment, and high flexibility.

Support USB clone function, easy to adjust.

Conventional boxes can be stacked up to 9 layers, and the average stacking cycle is about 8 seconds, which can meet the needs of a few extreme high-rises and has high stacking efficiencyAdopts foreign advanced rotary column stacking robot , the appearance is exquisile and beautiful ,the adjustment of stacking method is convenient and simple, which can be carried out on the man-machine interface, and also can be controlled by teach pendant ,which is easy to operate and change.

The rotate palletizer consists of the main system of the full servo palletizer by lifting Z axis, translation Y axis, rotating X

axis and gripper. At the same time, it can be combined with the pallet store station, the palletizing area conveyor line, the

feeding conveyor line, etc. to form a set Palletizing system. The palletizer puts the cartons on the pallet in a certain

arrangement for automatic stacking. It can stack multiple layers and then output, which is convenient for forklifts to transport to the warehouse for storage. This equipment adopts motion controller + teach 3 / 94 / 9 pendant control to realize intelligent operation management, simple and easy to master. Can greatly reduce labor and reduce labor intensity. System Components: This system is composed of the rotate palletizer, the gripper, the pallet store station, the case conveyors, the pallet conveyors, the safety fence and the control system.

Main technical Parameter

| Power Supply | AC380V/50HZ 20A -1p. |

| Power | 5.5KW |

| Weight | 950Kg |

| Working capacity | 2~6 movements/min |

| Speed | 0%-100% adjustable |

| Air pressure | 0.8MPa |

| Air consumption | 1000ml/min |

Be sure to use a separate fixed power supply. It is strictly forbidden to use a temporary line or use a power supply with other equipment. The voltage should not be lower than 360V or higher than 410V. When wiring, please check the live wire, neutral wire and ground wire (electrical damage and other damage caused by incorrect power supply). not included in the repair package).

Scheme structure

Scheme structure Debug machine

Debug machine Palletizing process

Palletizing process

| Palletizing Speed(bag/h) | 500-1500 | Place of Origin | China |

| Packaging Details | According to customer requirements | Product Name | Organic Fertilizer Palletizing Machine |

| Model Number | SLD-500 | Supply Ability | 100 units per month |

| Certification | CE,ISO | Brand Name | SLD |

| Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram | Palletizing Station (bag) | 4-8 |

| Lifting Height | 0-10M | Delivery Time | 5-10 days |

| Capacity | 0-100KG | Minimum Order Quantity | 1 |

| Gas Supply Pressure (Mpa) | 0.6-0.8 |

Product Description

Send Inquiry to This Supplier

You May Also Like

-

1kg/bag to 50 Kg/bag Automatic Bagging Filling Weighing Packaging Machine Powder / Particals Packing MachineUS$ 1 - 35000MOQ: 1 Set

-

1 Kg/bag to 50 Kg/bag Weighing-type Filling Machine Automatic Bag Weighing Packing Bag Filling Machine for Partical / PowderUS$ 1 - 35000MOQ: 1 Set

-

1000kg Per Bag Fertilizer Paste Material Ton Bulk Bag Auto Weighing Packing Machine Model 02US$ 1 - 35000MOQ: 1 Set

-

1000kg Per Bag Fertilizer Paste Material Ton Bulk Bag Auto Weighing Packing Machine Model 03 Bag Filling StationUS$ 1 - 35000MOQ: 1 Set

-

1000kg Per Bag Fertilizer Paste Material Ton Bulk Bag Auto Weighing Packing Machine Model 04 Bag Weighing Filling StationUS$ 1 - 35000MOQ: 1 Set

-

Big Bag Filling Station Weighing Bagging Bag Filling Machine Packing Scale Equipment 1000kg 500kg per BagUS$ 1 - 48000MOQ: 1 Set

-

BULB Big Bag Discharge Machine Heavy Duty Bulk Bag Unloader / Bulk Bag DischargerUS$ 1 - 48000MOQ: 1 Set

-

BULB Big Bag Discharge Machine Heavy Duty Bulk Bag Unloader / Bulk Bag DischargerUS$ 1 - 48000MOQ: 1 Set

-

High Position Automatic Palletizer Machine 500-1500 Bag Per HourUS$ 1 - 48000MOQ: 1 Set

-

Heavy Duty PLC Control Automatic Stretch Film Pallet Wrapping Packing MachineUS$ 1 - 48000MOQ: 1 Set