Construction of Rubber Dams: Technical Protocol & Best Practices

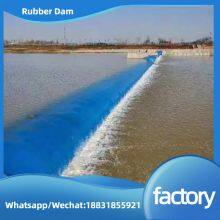

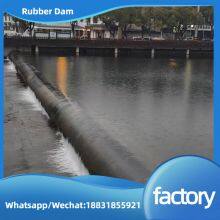

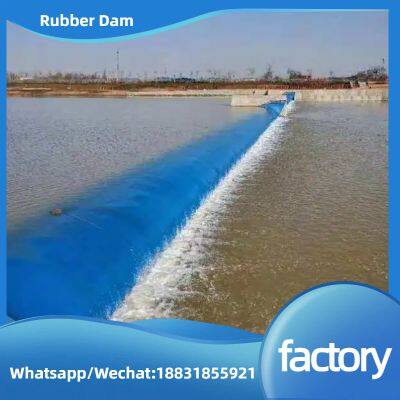

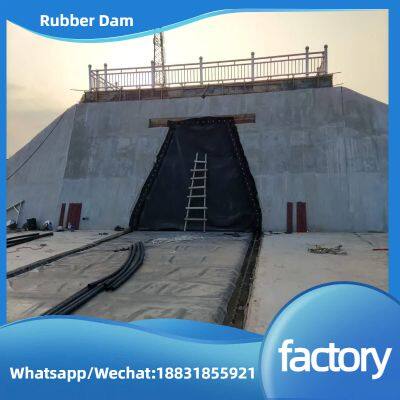

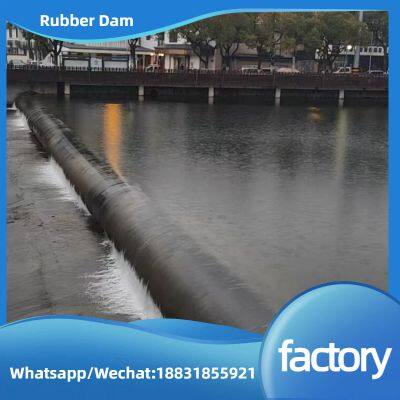

Rubber dams—flexible, inflatable hydraulic structures fabricated from high-performance synthetic rubber—demand specialized construction workflows to ensure air/water tightness, structural durability, and reliable operation in low-head water management scenarios (e.g., irrigation networks, urban water features, flood mitigation systems). The process is centered on

foundation rigidity, precise handling of the dam bag, and seamless integration of the inflation system, addressing the unique challenges posed by working with flexible materials. Below is a comprehensive, phase-by-phase breakdown of rubber dam construction, including technical specifications, quality control benchmarks, and industry-standard procedures.

1. Pre-Construction Phase: Planning & Preparation

Thorough pre-construction planning is critical to mitigate risks, align with design objectives, and ensure smooth execution—especially for the delicate dam bag and load-sensitive foundation.

1.1 Site Assessment & Design Validation

1.2 Material Sourcing & Quality Verification

Key materials must meet strict performance standards to ensure long-term reliability. The table below outlines critical specifications and inspection criteria:

1.3 Equipment & Safety Readiness

1.3 Equipment & Safety Readiness

Machinery: Excavators (10–15 ton, for foundation digging), vibratory rollers (compaction force ≥20 kN, for soil compaction), 10–20 ton mobile cranes (equipped with soft nylon slings to avoid dam bag damage), air/water pumps (matched to inflation system requirements).

Safety Equipment: Non-slip work boots, nitrile gloves (to prevent rubber scratches), life jackets (for near-water operations), temporary fencing (to secure the construction zone), and first-aid kits (stocked for cuts, abrasions, and water-related emergencies).

2. Foundation Construction: Building a Stable Base

A rigid, level foundation is essential to distribute inflation pressure evenly and prevent dam bag displacement. This phase focuses on soil stabilization and precise concrete work.

2.1 Site Clearing & Excavation

Debris Removal: Clear rocks, tree roots, and vegetation from the construction area. For riverbed sites, dredge silt and organic matter to expose stable soil or bedrock (minimum depth: 500mm) to eliminate foundation settlement risks.

Trench Excavation:

Width = dam bag width + 2× anchor plate width (typically 1.2–2m, depending on dam size).

Depth = 600–1000mm (adjusted for soil stability; deeper for soft soils).

Dig a rectangular trench along the dam’s centerline. Dimensions:

Slope trench walls at 1:1.5 to prevent collapse during construction.

2.2 Foundation Reinforcement

Soil Stabilization:

Concrete Base Pouring:

Pour a C30 reinforced concrete base (thickness 200–300mm) into the trench. Embed HRB400 steel reinforcement bars (diameter 12–16mm, spacing 200×200mm) to resist tensile stress and prevent cracking.

Use a laser level and screed board to ensure the concrete surface is level (flatness ≤3mm/m) and aligned with the dam’s centerline.

2.3 Anchoring System Installation

Bolt Positioning:

Use a precision steel template to place anchor bolts in the wet concrete. Ensure bolt spacing matches the dam bag’s edge holes (tolerance: ±2mm) to avoid misalignment during bag installation.

Extend bolts 100–150mm above the concrete surface (for dam bag clamping) and cover threads with plastic caps to protect against concrete contamination.

Concrete Curing:

Cover the concrete base with wet burlap or geotextile and cure for ≥14 days (maintain moisture to prevent shrinkage cracks). For temperatures<5°C, use insulation blankets to avoid freezing.

Test concrete compressive strength after 28 days (minimum requirement: 30 MPa) using cube samples before proceeding to dam bag installation.

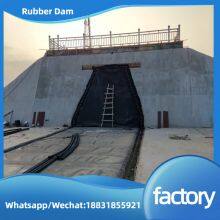

3. Rubber Dam Bag Installation: Precision Handling

The dam bag is the core functional component—installation requires careful handling to avoid damage, ensure alignment, and achieve air/water tightness.

3.1 Pre-Installation Preparation

3.2 Dam Bag Unfolding & Alignment

Unfolding:

For small dam bags (<20m long): Unroll manually along the protective pad—avoid dragging, as this scratches the rubber surface.

For large dam bags (>20m long): Use a crane with soft nylon slings (attached to pre-installed lifting lugs on the dam bag) to lift and unroll. Keep the bag taut but not stretched (overstretching damages the fabric reinforcement and reduces lifespan).

Alignment:

Adjust the dam bag so its edge holes align with the anchor bolts (tolerance: ±5mm). Use string lines to verify alignment with the dam’s centerline.

Position the dam bag’s inflation valve near the pump station to minimize pipeline length and pressure loss.

3.3 Anchoring & Sealing

4. Inflation/Deflation System Setup

The inflation system controls dam height and responsiveness—installation focuses on leak-proof connections and accurate pressure monitoring.

4.1 Pipeline & Equipment Installation

4.2 System Testing

5. Auxiliary Structures Installation

These components protect the dam bag and foundation, enhancing long-term performance and reducing maintenance needs.

Trash Racks: Install steel trash racks upstream of the dam (aligned with the channel width) to block debris (e.g., branches, rocks) from contacting the dam bag. Ensure racks are removable for periodic cleaning.

Downstream Protective Pads: Place rubber pads (5–10mm thick) along the downstream edge of the concrete foundation to reduce abrasion from flowing water or sediment.

Groundwater Drainage: Install perforated PVC pipes (diameter 100mm) behind the foundation, sloped at 1:100 toward the channel. This drains groundwater and prevents hydrostatic pressure from lifting the foundation.

6. Commissioning & Acceptance

Summary

Rubber dam construction requires meticulous attention to technical details—from foundation stability to dam bag sealing—to leverage the structure’s flexibility, cost-effectiveness, and low maintenance benefits. By adhering to strict material standards, precise installation techniques, and comprehensive testing, the final structure delivers reliable performance in low-head water control applications.