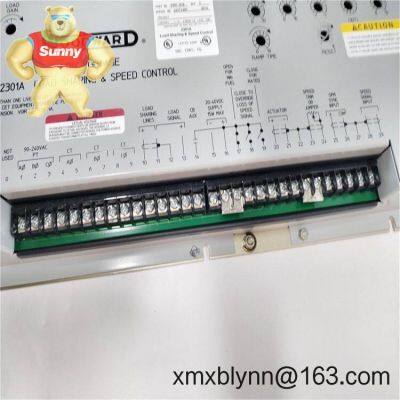

Woodward 9907-018 – Load Sharing & Speed Control for Gensets and Industrial Engines

The Woodward 9907-018 is a 2301A-series speed control designed for precise engine governing and reliable load sharing across paralleled generator sets. It’s the kind of analog controller that technicians reach for when they want steady isochronous speed, clean kW sharing, and a straightforward setup without a laptop.

From my experience, this model fits well in retrofit and upgrade projects where you need dependable control, minimal downtime, and compatibility with standard 0–200 mA electric actuators. You might notice it’s especially practical in applications where stable frequency and quick response to load transients matter.

Key FeaturesIsochronous and droop control – Supports tight frequency regulation or intentional droop for paralleled operation.

Load sharing capability – Shares kW via the standard analog load sharing line, typically reducing circulating current and mismatch issues.

MPU speed input – Accepts a magnetic pickup signal for robust and noise-resistant speed sensing.

Actuator drive (0–200 mA) – Drives Woodward proportional electric actuators commonly used on diesel and gas engines.

Analog tuning – On-board trimpots for gain, stability, and droop; no software required, which in many cases speeds up commissioning.

Retrofit-friendly form factor – Typically panel or backplate mounted, making it simple to drop into existing cabinets.

Proven field reliability – The 2301A lineage is widely used in power gen and oil & gas, so spare parts and know-how are easy to source.

| Brand / Model | Woodward 9907-018 (2301A series) |

| Control Type | Engine speed control with load sharing (isochronous/droop) |

| Power Requirements | 24 Vdc nominal (typical for this variant) |

| Speed Input | Magnetic pickup (MPU) from engine flywheel or gear |

| Actuator Output | Proportional current, typically 0–200 mA |

| Load Sharing Interface | Analog load sharing line for paralleled gensets |

| Communication | N/A (analog controller; no fieldbus) |

| Installation Method | Panel/backplate mounting inside a control cabinet |

| Operating Temperature | Industrial range (typical for 2301A-class controls) |

| Dimensions & Weight | Compact controller; consult the 9907-018 outline drawing for exact values |

Prime and standby generator sets on industrial sites and healthcare facilities

Oil & gas compressor packages and pump drives where stable RPM is critical

Marine auxiliary gensets and propulsion support systems

Mining and construction power modules that need simple, serviceable controls

Retrofits replacing aging governors with a clean analog 2301A solution

A supervisor at a power rental fleet mentioned the 9907-018 “settled faster on load steps than the old unit,” and the team appreciated that tuning was intuitive. That seems to be a recurring theme in the field.

Reliability under real-world conditions – Stable governing in most cases even with electrical noise and variable loads.

Compatibility – Works with standard Woodward proportional actuators and typical MPU speed pickups, easing spares management.

Lower lifecycle cost – No software licenses; quick field tuning often reduces commissioning time.

Procurement confidence – Long-running 2301A platform means predictable lead times and broad service know-how.

Cabinet & environment – Install inside a clean, dry, ventilated control cabinet (NEMA/IEC equivalent). Keep clear of high-vibration or high-heat zones.

Power & wiring – Use a clean 24 Vdc supply (fused). Route the MPU cable separately from high-voltage lines and use shielded twisted pair with proper grounding.

Actuator loop – Verify actuator current range (typically 0–200 mA) and confirm linkage is free from binding before tuning.

Tuning – Start with conservative gain/stability settings; step-load the generator and trim for response without overshoot.

Routine checks – Inspect connectors, verify speed pickup gap per sensor spec, and re-validate droop/isochronous settings after major service.

Spares – Keep an MPU and actuator on hand; they’re the most common wear/field-replace items around this controller.

CE marking – Conforms to applicable EMC and safety directives for industrial controls.

UL/cUL or CSA (variant-dependent) – Many 2301A builds carry North American safety approvals; confirm on the unit nameplate.

ISO 9001 manufacturing – Produced under certified quality systems.

RoHS (current production) – Compliance may apply to current builds; legacy spares can vary by date code.

Warranty – Standard manufacturer’s warranty terms apply; we typically see 12 months from commissioning or 18 months from shipment, whichever comes first.

Send Inquiry to This Supplier

You May Also Like

-

Woodward 9907-162 (2301E Series) – Digital Load Sharing & Speed Control for Engines and GensetsNegotiableMOQ: 1 Bag

-

Woodhead PCU2000ETH: Bridge Legacy PLCs to Modern Ethernet NetworksNegotiableMOQ: 1 Bag

-

Woodward 5466-1035 Controller Module: Rock-Solid Control for Critical Power SystemsNegotiableMOQ: 1 Bag

-

Woodward 8256-021: Reliable Speed Control for Industrial Turbines and EnginesNegotiableMOQ: 1 Bag

-

Woodward 8237-1600: Rock-Solid Speed Control for Gas Turbines When It Matters MostNegotiableMOQ: 1 Bag

-

Woodward 8256-016: Reliable Speed Control for Industrial Turbines & GeneratorsNegotiableMOQ: 1 Bag

-

Woodward 8290-184: Your Go-To Electronic Governor for Diesel Engine Speed StabilityNegotiableMOQ: 1 Bag

-

WOODWARD 8407-523 Gas Controller Valve: Precision Fuel Management for Critical Combustion SystemsNegotiableMOQ: 1 Bag

-

WOODWARD 8440-1934: The No-Nonsense Turbine Guardian You Can Rely OnNegotiableMOQ: 1 Bag

-

Woodward 8577-825 Linear Actuator: Precision Turbine Control for Demanding EnvironmentsNegotiableMOQ: 1 Bag