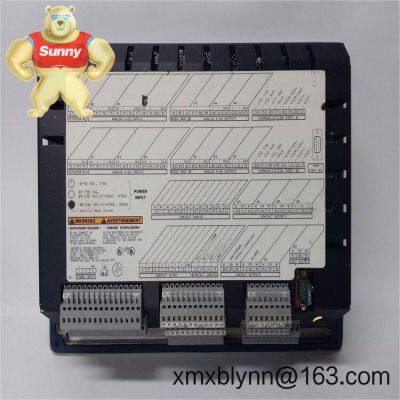

Woodward 9907-162 (2301E Series) – Digital Load Sharing & Speed Control for Engines and Gensets

The Woodward 9907-162 is a 2301E-series digital controller built to regulate prime mover speed and enable precise load sharing in generator applications. It’s widely used on diesel and gas engines where stable isochronous speed control, smooth load transfer, and reliable parallel operation really matter. In many cases, it drops into existing cabinets with minimal rework, yet gives you more tuning headroom than older analog 2301A/D setups.

Key FeaturesDigital speed control (isochronous & droop) – Maintains steady RPM under varying loads; droop mode supports grid-parallel operation.

Integrated load sharing – Coordinates with other controllers to balance kW across gensets, typically without hunting or oscillation.

MPU speed pickup input – Standard magnetic pickup support for robust, noise-tolerant speed sensing on industrial engines.

Electric actuator drive – Current output for Woodward actuators; from my experience this simplifies retrofit work and speeds commissioning.

Raise/Lower and remote setpoint – Accepts external commands (e.g., analog ref) for supervisory control and SCADA tie-in.

Ramp/soft transfer functions – Smoother load application and unloading, which helps protect mechanical systems and downstream gear.

Field-tunable parameters – Gain, stability, and limits can be adjusted to match engine dynamics and application specifics.

Industrial temperature design – Built for cabinet-mounted, harsh-duty environments typically seen in power, oil & gas, and marine.

| Brand / Model | Woodward 9907-162 (2301E Load Sharing & Speed Control) |

| Power Requirements | 24 Vdc nominal (typically 18–32 Vdc) |

| Operating Temperature | Industrial range; commonly –40 to +70°C (application dependent) |

| Signal Inputs | MPU speed pickup; discrete raise/lower; remote speed/load reference (analog) |

| Signal Outputs | Electric actuator current drive (e.g., Woodward actuators); analog feedback available on this series |

| Control Modes | Isochronous, droop, load sharing, ramp/soft transfer |

| Installation Method | Panel/backplate mounting in a ventilated control cabinet |

| Configuration | PC-based service tool via service port; on-site tuning of gains and limits |

Typical deployments include genset control (islanded or paralleled), engine-driven pumps and compressors, CHP/biogas units, and marine auxiliaries. You might notice it’s especially handy when upgrading older analog speed controls to digital while keeping proven Woodward actuators and magnetic pickups. One maintenance lead told me they swapped to the 9907-162 on a three-set plant and saw faster synchronization and calmer load steps during peak hours.

Reliability – Industrial-grade build; once tuned, it tends to run for years with very little drift.

Compatibility – Works with standard MPUs and Woodward electric actuators, so retrofit risk is lower and wiring stays familiar.

Performance stability – Digital algorithms reduce hunting; load sharing feels tighter on multi-set plants.

Lifecycle cost – Fewer nuisance trips and quicker commissioning can translate into real savings over the unit’s service life.

Technical ecosystem – Broad Woodward portfolio support, spares availability, and well-documented tuning procedures.

Cabinet & environment – Mount on a rigid backplate inside a clean, dry, ventilated enclosure. Avoid high-vibration spots or hot zones near exhaust manifolds.

Wiring practices – Use twisted-shielded pair for the MPU leads and analog references; separate from high-voltage and contactor runs. Ensure a solid 24 Vdc supply with proper grounding.

Actuator/drive checks – Verify actuator current limits and linkage free-travel before live tests; set mechanical stops conservatively at first.

Tuning workflow – Start with conservative gain/stability; perform no-load speed stability checks, then step-load tests, and finally parallel load sharing trimming.

Routine tasks – Visual inspection for loose terminals and dust; periodic calibration checks; backup the configuration file after any change; firmware updates where applicable.

Safety – Lockout/tagout before wiring; confirm E‑stop and shutdown circuits function independently of the governor control.

Certifications – CE compliant and RoHS aligned for typical industrial markets; many installations also use UL/cUL listed panels.

Manufacturing quality – Built for continuous-duty prime mover service; traceable components and documented QA processes.

Warranty – Standard limited warranty from the manufacturer (commonly 24 months from shipment) on properly installed units.

If you’re comparing the 9907-162 to older 2301A/2301D hardware, the step-up usually shows in tighter load sharing and easier parameter management. Send over your actuator type, pickup gearing, and any paralleling scheme notes—happy to sanity-check compatibility before you commit.

Send Inquiry to This Supplier

You May Also Like

-

UTLH21 Microprocessor Module Ability to Process Data and Run Applications QuicklyNegotiableMOQ: 1 Bag

-

9907-1183 505E Turbine Controller It Can be Configured as an Independent DeviceNegotiableMOQ: 1 Bag

-

8237-1246 Overspeed Safety Device Relay OutputNegotiableMOQ: 1 Bag

-

810-102361-222 Rocker Arm Valve Interface Board The Valve is Under Positive VoltageNegotiableMOQ: 1 Bag

-

9907-1200 Stable Linear Valve Control Excellent Accuracy and ResolutionNegotiableMOQ: 1 Bag

-

8200-1300 505 Turbine Monitor the Microprocessor and Its MemoryNegotiableMOQ: 1 Bag

-

9905-864 Processor Controller Ensure Stable Operation of Steam TurbineNegotiableMOQ: 1 Bag

-

5466-409 Digital Control Series Single Ethernet Port for High ProcessingNegotiableMOQ: 1 Bag

-

5464-414 Digital Speed Sensor A Loop That Provides Control SignalsNegotiableMOQ: 1 Bag

-

TRAFOTEK CHK0520 Line Output Reactor Reduce Harmonic Interference and Improve System StabilityNegotiableMOQ: 1 Bag