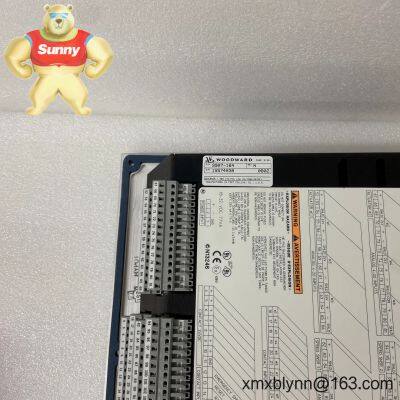

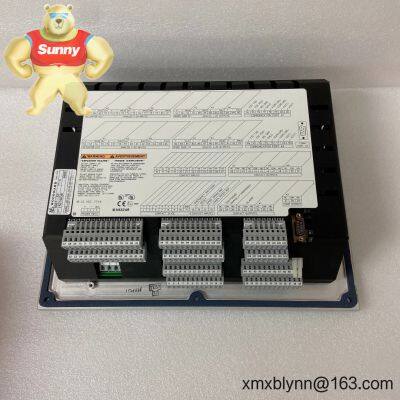

Woodward 9907-165 – 2301A Load Sharing & Speed Control for Engine and Generator Governing

The Woodward 9907-165 is a 2301A-series analog governor controller designed for precise speed control and load sharing on engine-driven equipment and generator sets. It’s a proven choice when you need stable isochronous operation, straightforward paralleling, and reliable actuator drive without the overhead of a fully digital system.

In many cases, it’s used to modernize or replace legacy governors on diesel or gas engines while keeping wiring simple and service-friendly. From my experience, it strikes a solid balance between robustness and ease of tuning in everyday plant environments.

Key FeaturesIsochronous and Droop Speed Control – Supports tight isochronous control for stand‑alone sets, with droop mode for stable paralleling.

Load Sharing Capability – Analog load-sharing line enables smooth kW balancing across multiple gensets on a common bus.

MPU Speed Sensing – Accepts magnetic pickup input for accurate, noise‑resistant speed feedback on rotating shafts.

Proportional Actuator Drive – Current output to Woodward proportional actuators provides fast, stable fuel control in most engine applications.

Remote Speed/Trim Inputs – Compatible with remote potentiometer or analog reference to adjust setpoint from a panel or PLC analog card.

Simple Front-Panel Tuning – Gain, stability, and droop trims on the face make commissioning and field adjustments quick.

Discrete Control Inputs – Typical idle/rated and raise/lower functions simplify operator control without complex HMI logic.

Rugged, Analog Architecture – Fewer firmware dependencies and excellent tolerance to electrical noise compared with some digital units.

The 9907-165 is typically deployed on:

Generator Sets – Isochronous control for standalone sets and droop/load sharing for parallel operation on common busbars.

Industrial Engines – Speed governing for pumps, compressors, and fans where stable RPM and quick load response are essential.

Marine & Offshore Packages – Robust performance in engine rooms with electrical noise, using shielded MPU wiring and proper grounding.

Retrofit Projects – Drop‑in replacement for aging analog governors to reduce downtime and keep maintenance straightforward.

A maintenance supervisor told me their team swapped in a 9907-165 on a 1.5 MW genset and had it sharing load within an hour—no PLC rework, just a tidy tune of stability and droop.

Reliability – Mature hardware that, in most cases, runs for years with only minimal recalibration.

Compatibility – Works with common Woodward proportional actuators and standard MPU pickups; easy to integrate in existing cabinets.

Cost Control – Analog simplicity often reduces commissioning time and avoids the learning curve of complex digital HMIs.

Serviceability – Front‑panel trims and clear terminal design help technicians diagnose and fine‑tune quickly during outages.

Cabinet & Environment – Mount on a rigid back‑panel within a ventilated control cabinet. Keep away from high‑heat sources and high‑frequency drives where practical.

Power & Grounding – Use clean 24 Vdc supply with proper grounding. Star‑point grounding and segregated instrument earth typically help reduce noise.

Wiring Practices – Route the MPU cable as shielded, twisted pair; ground the shield at one end only. Keep load‑sharing and speed‑trim lines away from power conductors.

Actuator Tuning – After initial start, adjust gain/stability gradually. Set droop or isochronous to match operating mode, then validate transient response under step loads.

Routine Checks – Periodically verify terminal tightness, inspect MPU gap, and confirm speed setpoint accuracy. Light dust cleaning keeps the unit and terminals in good shape.

Spare Strategy – Many sites keep one 9907‑165 on the shelf; swap‑time is usually short, which helps minimize outage risk.

Quality System – Manufactured under ISO 9001‑certified processes.

Compliance – CE and RoHS compliance typically available for the 2301A family; UL/cUL recognition is common for panel-installed controls.

Warranty – Manufacturer’s limited warranty, often 2 years from shipment; actual terms can vary by region and project.

If you’re replacing an older analog governor or need a dependable controller for parallel gensets without adding complexity, the Woodward 9907-165 seems to be the practical, technician-friendly choice.

Send Inquiry to This Supplier

You May Also Like

-

Woodward 8256-021: Reliable Speed Control for Industrial Turbines and EnginesNegotiableMOQ: 1 Bag

-

Woodward 8237-1600: Rock-Solid Speed Control for Gas Turbines When It Matters MostNegotiableMOQ: 1 Bag

-

Woodward 8256-016: Reliable Speed Control for Industrial Turbines & GeneratorsNegotiableMOQ: 1 Bag

-

Woodward 8290-184: Your Go-To Electronic Governor for Diesel Engine Speed StabilityNegotiableMOQ: 1 Bag

-

WOODWARD 8407-523 Gas Controller Valve: Precision Fuel Management for Critical Combustion SystemsNegotiableMOQ: 1 Bag

-

WOODWARD 8440-1934: The No-Nonsense Turbine Guardian You Can Rely OnNegotiableMOQ: 1 Bag

-

Woodward 8577-825 Linear Actuator: Precision Turbine Control for Demanding EnvironmentsNegotiableMOQ: 1 Bag

-

Woodward 9907-163 Digital Turbine Controller: Precision Control for Critical Power AssetsNegotiableMOQ: 1 Bag

-

WOODWARD 9908-201 Hydraulic Hose Assembly for Critical Control SystemsNegotiableMOQ: 1 Bag

-

Woodward EGCP-2: Precision Turbine Control Where Reliability MattersNegotiableMOQ: 1 Bag