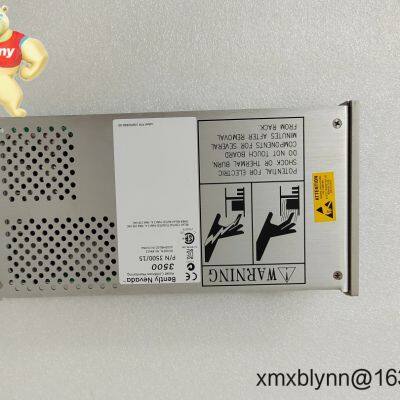

Bently Nevada 3500/15-04-04-01 Power Supply Module – Stable DC Power for 3500 Machinery Protection Racks

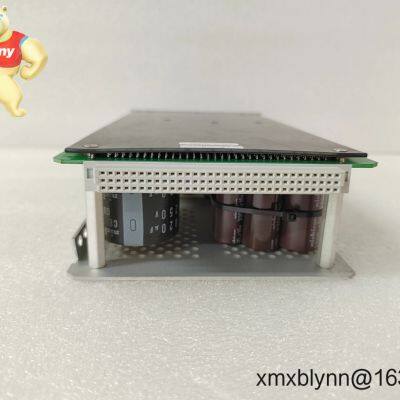

The Bently Nevada 3500/15-04-04-01 is a full-height power supply module designed to feed the 3500 rack and its monitoring cards with clean, stable DC power. It supports redundant operation for high availability, so most sites keep two installed to maintain protection coverage during a supply swap. From my experience, it’s the kind of “fit-and-forget” component that quietly keeps critical turbomachinery protection online day after day.

Based on typical Bently Nevada option coding, the “-04” input variant corresponds to telecom-grade –48 Vdc (often operating across a 36–72 Vdc range). If your site standardizes on –48 Vdc panels, this module usually drops straight in with minimal panel changes.

Key FeaturesDesigned for the 3500 rack – Supplies regulated DC to the backplane for all monitoring and communication modules.

Redundant-ready – Install a second 3500/15 for seamless failover; you can replace one unit while the other carries the load.

–48 Vdc input (typical for “-04”) – Suits telecom/utility environments; helps standardize on existing DC infrastructure.

Front-panel status LEDs – Quick visual confirmation of OK/active status, which operators appreciate during round checks.

Full-height module – Fits the dedicated power bays of the 3500 rack; no special brackets or custom hardware.

Noise-immune design – In many cases reduces susceptibility to panel noise and voltage dips that can trip sensitive cards.

Proven reliability – Typically runs for years with only basic dust cleaning; no routine firmware handling required.

| Brand / Model | Bently Nevada 3500/15-04-04-01 Power Supply Module |

| Power Requirements | –48 Vdc input (commonly 36–72 Vdc range for “-04” variants; verify against site drawing) |

| Output to Rack | Regulated DC to 3500 backplane (internal distribution only) |

| Signal I/O Types | N/A (no field I/O; power-only module) |

| Communication Interfaces | None on PSU; system comms via modules such as 3500/22M |

| Form Factor | Full-height 3500 rack module; supports dual-redundant installation |

| Operating Temperature | Typically 0 to +65 °C (rack environment) |

| Installation Method | Rack-mounted in 3500 power supply bay; tool-less front insertion with rear backplane connection |

Most users deploy the 3500/15-04-04-01 in –48 Vdc panels supporting the Bently Nevada 3500 machinery protection system. Typical sites include:

Steam and gas turbines in power generation (base-load and peaker plants).

Compressors and expanders in oil & gas gathering, midstream, and refining.

Large pumps, fans, and motors in chemical plants and paper mills.

Offshore platforms where –48 Vdc supplies are standard for critical systems.

High availability – Redundant configuration means a single PSU fault won’t compromise protection.

Lower integration effort – If your MCCs already provide –48 Vdc, wiring is straightforward in most cases.

Lifecycle stability – The 3500 platform has a long service tail, which simplifies spares planning.

Compatibility certainty – Purpose-built for the 3500 rack; no third-party conversion hardware needed.

Serviceability – Clear front indicators and hot-replacement (when redundant) help reduce downtime.

“We run dual 3500/15s on our compressor trains. Swapped one during a turnaround without taking the rack offline—operators barely noticed it happened.” — Maintenance Supervisor, petrochemical siteInstallation & Maintenance

Panel power – Verify –48 Vdc polarity and that available current meets rack load (consider peak inrush). Use correctly rated fusing and a clean ground reference.

Rack environment – Keep within typical 0–65 °C ambient, with adequate ventilation. Avoid high vibration on the panel door.

Redundancy practice – For live replacement, install two supplies. Replace only one at a time; confirm the remaining PSU OK/active before removal.

Wiring – Use shielded DC cabling where practical and follow facility standards for cable separation from high-noise sources.

Routine care – Quarterly visual check for status LEDs and connection integrity; annual light dust cleaning with dry air. No regular firmware updates required for the PSU.

Documentation – Match the “-04-04-01” options to your site spec sheet to confirm input and approvals before energization.

Industry certifications for the 3500 series typically include CE and UL/cUL; RoHS compliance is common on recent builds. Specific approvals can vary by option code.

Manufacturer’s warranty is typically 1 year from shipment, assuming standard operating conditions.

Bently Nevada 3500/05 Rack – The chassis that houses power, monitoring, and comms modules.

Bently Nevada 3500/22M – System communications module for data integration to DCS/OSIsoft PI, etc.

Bently Nevada 3500/32M, 3500/40M, 3500/42M – Common monitoring cards for vibration, temperature, and position.

One thing I appreciate is how predictable the 3500/15 behaves under brownout conditions—if the panel feed is well designed, nuisance trips are rare. If your facility uses a mix of AC and DC feeds across units, I can help cross-check whether a –48 Vdc “-04” supply or an AC variant will simplify your spare strategy.

Send Inquiry to This Supplier

You May Also Like

-

Bently Nevada 330101-00-20-05-02-05 Proximity Probe for 8 mm Vibration/Displacement MonitoringNegotiableMOQ: 1 Combo

-

Bently Nevada 3500/25 (125800-01) Keyphasor Module – Stable Phase Reference and Speed Input for the 3500 SystemNegotiableMOQ: 1 Combo

-

Bently Nevada 330101-00-66-10-02-05 – Non‑contact Vibration and Displacement Sensing for Rotating MachineryNegotiableMOQ: 1 Combo

-

Bently Nevada 40113-02 – Protect Probe-to-cable Connectors in Demanding Machinery EnvironmentsNegotiableMOQ: 1 Combo

-

Bently Nevada 45358-09 – Extension Cable for Proximity Probe SystemsNegotiableMOQ: 1 Combo

-

Bently Nevada 3500/33-SIL-01 Relay Module – Safety-rated Alarm Relays for the 3500 Protection SystemNegotiableMOQ: 1 Combo

-

Bently Nevada 330130-045-00-00 Extension Cable – 3300 XL Proximity System CablingNegotiableMOQ: 1 Combo

-

Bently Nevada 125680-01 Sensor Module – Purpose-built for Centrifugal Compressor MonitoringNegotiableMOQ: 1 Combo

-

Bently Nevada 330130-040-00-05 Extension Cable – for 3300 XL Proximity Transducer SystemsNegotiableMOQ: 1 Combo

-

Bently Nevada RAO00027 Accelerometer – Casing Vibration Sensor for Centrifugal CompressorsNegotiableMOQ: 1 Combo