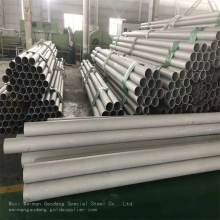

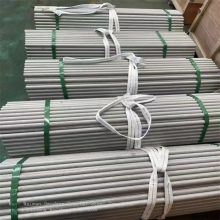

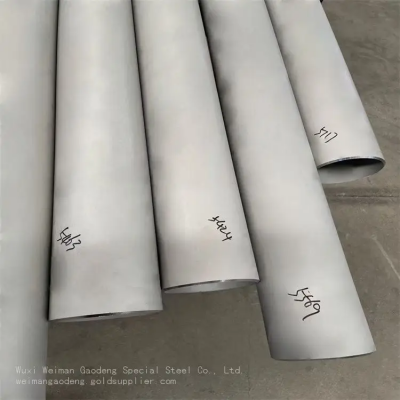

Long Lasting Stainless Steel Pipes F44/S31254/1.4547/XM19 Direct Factory Supply for Aerospace and Automotive Tubing

Product Overview

Our long - lasting stainless steel pipes, available in specifications F44, S31254, 1.4547, and XM19, are a prime choice for aerospace and automotive tubing applications. These pipes are directly supplied from our factory, ensuring high - quality and cost - effective solutions for our international customers.

Material and Surface Treatment

- Material Composition: These stainless steel pipes are crafted from high - grade stainless steel. The specific alloys in F44, S31254, 1.4547, and XM19 offer excellent corrosion resistance, high strength, and good ductility. This makes them suitable for use in harsh environments, whether it's the high - stress conditions in aerospace or the varying weather and chemical exposure in automotive applications.

- Surface Treatment: The pipes undergo a polishing surface treatment. This not only gives them an aesthetically pleasing finish but also provides additional benefits. A polished surface reduces friction, which is crucial in tubing applications where fluid flow is involved. It also helps in preventing the accumulation of dirt and debris, which could potentially cause blockages or corrosion over time.

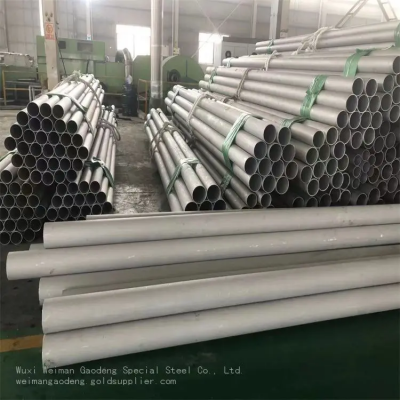

Manufacturing Technique and Standard

- Technique: The pipes are manufactured using the hot - rolled technique. Hot rolling allows for the production of pipes with uniform wall thickness and excellent mechanical properties. During the hot - rolling process, the steel is heated to a high temperature and then passed through rollers to achieve the desired shape and dimensions. This process enhances the strength and durability of the pipes.

- Standard: Our stainless steel pipes adhere to the ASTM standard. This is an internationally recognized standard that ensures the quality, performance, and safety of the products. By meeting the ASTM standard, our pipes can be trusted to perform reliably in aerospace and automotive applications, where strict quality requirements are in place.

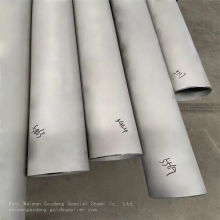

Shape and Dimensions

- Shape: The pipes have a round shape, which is the most common and practical shape for tubing applications. A round shape provides uniform stress distribution, making the pipes more resistant to internal and external pressures. It also allows for smooth fluid or gas flow, which is essential in both aerospace and automotive systems.

- Dimensions: We offer a wide range of dimensions to meet the diverse needs of our customers. Whether you need pipes with a small outer diameter for delicate aerospace components or larger pipes for automotive exhaust systems, we can provide customized solutions. Our custom - cutting services can produce pipes with outer diameters ranging from 20mm to 1200mm, ensuring that we can cater to various application requirements.

Applications in Aerospace and Automotive Industries

- Aerospace: In the aerospace industry, our stainless steel pipes are used in a variety of applications. They can be found in hydraulic systems, where their high - strength and corrosion - resistant properties ensure reliable operation under extreme conditions. They are also used in fuel lines, where the smooth interior surface provided by the polishing treatment helps in efficient fuel flow. Additionally, these pipes are suitable for use in aircraft engine components, where they need to withstand high temperatures and pressures.

- Automotive: For the automotive industry, our pipes are ideal for exhaust systems. The corrosion resistance of the stainless steel ensures a long service life, even when exposed to harsh exhaust gases and road salts. They can also be used in brake lines, where their strength and durability are crucial for the safety of the vehicle. The round shape of the pipes allows for easy installation and connection in automotive tubing systems.

Company - Backed Quality Assurance

- Manufacturing Expertise: Our company, established in 2017, is a manufacturer with a rich history of technological development. We have evolved from a research - and - development - focused startup to a global special - steel solution provider. Our manufacturing facilities are equipped with advanced automated lines that cover the production of stainless steel, nickel alloys, titanium, and forgings up to 20m in length.

- Testing and Quality Control: We have comprehensive processing and testing capabilities. Our welded elbows and flanges are produced per ASME B16.9 standards and undergo radiographic testing (RT) and liquid penetrant testing (PT) to ensure their integrity. We also offer advanced non - destructive testing (NDT) services, including ultrasonic testing (UT) to EN 10228 - 3, which can detect internal defects as small as 0.5mm, and magnetic particle testing (MT) for surface cracks, certified by SGS and BV.

- Global Partnerships and Compliance: We collaborate with global partners such as SGS and BV for third - party audits, ensuring that our products align with ISO 17025 standards. We also maintain long - term agreements with German DMV Mannesmann and Spanish Tubacex for premium alloy sourcing. Our products comply with international standards such as ASTM, EN, JIS, and API, making them suitable for the global market. With an export share of US$5 Million - US$10 Million, we have a proven track record of serving customers in North America, South America, Europe, Asia, Africa, and Oceania.

By choosing our long - lasting stainless steel pipes for your aerospace and automotive tubing needs, you are getting a high - quality product backed by a reliable and experienced manufacturer.

Send Inquiry to This Supplier

You May Also Like

-

S25073/2507/1.4435/724L Cost Effective Stainless Steel Pipes Factory Price for Mining and Heavy Machinery TubingNegotiableMOQ: 1 Ton

-

Trusted Manufacturer for Hydraulic and Pneumatic Systems Reliable Quality Stainless Steel Pipes 174PH/SUS630/F51/2205NegotiableMOQ: 1 Ton

-

Industrial Grade Stainless Steel Pipes SUS631/177PH/S31803/F52 Factory Direct for Architectural Decoration and Structural UseNegotiableMOQ: 1 Ton

-

S32950/F53/2507/S32750 Manufacturer Supply For Pressure Vessels and Pipelines Heavy DutyNegotiableMOQ: 1 Ton

-

Marine Grade S32760/F55/F60/S32205 Stainless Steel Pipes Factory Made for Marine and Coastal Engineering ProjectsNegotiableMOQ: 1 Ton

-

Chemical Resistant Stainless Steel Pipes SUS329J1/1.4460/254SMO/F44 Factory Supply for Chemical Storage TanksNegotiableMOQ: 1 Ton

-

High Temperature Resistant Stainless Steel Pipes S31254/1.4547/XM19/S20910 Professional Manufacturer for Semiconductor IndustryNegotiableMOQ: 1 Ton

-

High Pressure Stainless Steel Pipes Gr660/SUH660/316Ti/S31668 Factory Direct for Industrial Pipeline SystemsNegotiableMOQ: 1 Ton

-

Custom Size 1.4529/N08367/N08926/S31608 Stainless Steel Pipes Manufacturer for Oil and Gas RefineriesNegotiableMOQ: 1 Ton

-

Efficient Heat Transfer Stainless Steel Pipes S31609/316H/347H/SUS34778 Factory Price for Thermal Power Plant Heat ExchangersNegotiableMOQ: 1 Ton