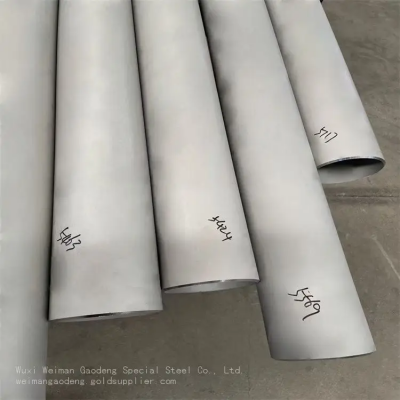

Superior Performance Stainless Steel Pipes S321H/S32169/317L/S31703 Factory Supply for Nuclear Power and Refinery Applications

Superior Performance Stainless Steel Pipes S321H/S32169/317L/S31703 Factory Supply for Nuclear Power and Refinery Applications

1. Product Overview

Our stainless steel pipes, including S321H, S32169, 317L, and S31703, are specifically designed for high - demand applications in nuclear power and refinery industries. These pipes are the result of advanced manufacturing techniques and strict quality control, ensuring they meet the most rigorous international standards.

2. Material and Surface Treatment

- Material: Made from high - grade stainless steel, these pipes offer excellent corrosion resistance, high strength, and good ductility. The specific grades S321H and S32169 contain titanium stabilizers, which enhance their resistance to intergranular corrosion, especially at elevated temperatures. The 317L and S31703 grades have a higher molybdenum content, providing superior resistance to pitting and crevice corrosion in aggressive chemical environments.

- Surface Treatment: The pipes undergo a polished surface treatment. This not only gives them an aesthetically pleasing appearance but also reduces the surface roughness, minimizing the risk of particle adhesion and corrosion initiation. The smooth surface also makes the pipes easier to clean, which is crucial in industries where hygiene and purity are of utmost importance.

3. Manufacturing Technique

These pipes are manufactured using the hot - rolled technique. Hot rolling involves heating the steel billets to a high temperature and then passing them through rollers to achieve the desired shape and dimensions. This process offers several advantages. Firstly, it improves the mechanical properties of the steel, such as its strength and toughness. Secondly, it allows for the production of pipes with large diameters and thick walls, which are often required in nuclear power and refinery applications. The hot - rolled pipes also have a more uniform grain structure, enhancing their overall performance and reliability.

4. Shape and Standard Compliance

- Shape: The pipes are round in shape, which is the most common and practical shape for fluid transportation in nuclear power and refinery systems. The round shape provides uniform stress distribution, ensuring that the pipes can withstand high internal pressures without deformation.

- Standard Compliance: Our stainless steel pipes strictly adhere to the ASTM standard. ASTM standards are widely recognized and respected in the international market, ensuring that the pipes meet the quality and performance requirements of various industries. By complying with ASTM standards, our pipes are suitable for use in a wide range of applications, both domestically and internationally.

5. Application in Nuclear Power and Refinery Industries

- Nuclear Power: In nuclear power plants, these pipes are used for various critical applications. They are employed in the primary coolant circuits, where they need to withstand high temperatures, high pressures, and radiation. The excellent corrosion resistance of the stainless steel ensures the long - term integrity of the pipes, preventing leaks and ensuring the safe operation of the nuclear power plant. They are also used in the secondary systems for steam generation and heat transfer.

- Refinery: In refineries, the pipes are used for transporting various chemicals, crude oil, and refined products. The high corrosion resistance of the 317L and S31703 grades makes them ideal for handling aggressive chemicals such as sulfuric acid, hydrochloric acid, and chloride - containing solutions. The S321H and S32169 grades are suitable for applications where high - temperature stability is required, such as in cracking units and reformers.

6. Company - Backed Quality Assurance

We are a manufacturer with a rich history and a strong technical team. Since our establishment in 2017, we have been committed to providing high - precision special steel solutions. Our company has obtained ISO 9001:2015, API 5L, and EU PED certifications, which are testaments to our strict quality management system. We have advanced processing and testing capabilities, including radiographic testing (RT), liquid penetrant testing (PT), ultrasonic testing (UT), and magnetic particle testing (MT). These testing methods ensure that every pipe leaving our factory meets the highest quality standards. Our team of experts, including ASME - certified NDT Level III inspectors and NADCAP - qualified engineers, is dedicated to ensuring the quality and performance of our products.

7. Global Reach and Logistics

We have a significant export share, ranging from US$5 Million - US$10 Million, and our products are sold in major markets around the world, including North America, South America, Europe, Asia, Africa, and Oceania. We have strategically located warehouses in Wuxi, which allows us to provide rapid logistics services. We can ensure 48 - hour delivery to major Chinese ports, enabling timely shipment and reducing the lead time for our international customers.

In conclusion, our Superior Performance Stainless Steel Pipes S321H/S32169/317L/S31703 are the ideal choice for nuclear power and refinery applications. With their excellent material properties, strict standard compliance, and reliable manufacturing, they offer a high - performance and cost - effective solution for your industrial needs.

Send Inquiry to This Supplier

You May Also Like

-

Chemical Resistant Stainless Steel Pipes SUS329J1/1.4460/254SMO/F44 Factory Supply for Chemical Storage TanksNegotiableMOQ: 1 Ton

-

High Temperature Resistant Stainless Steel Pipes S31254/1.4547/XM19/S20910 Professional Manufacturer for Semiconductor IndustryNegotiableMOQ: 1 Ton

-

High Pressure Stainless Steel Pipes Gr660/SUH660/316Ti/S31668 Factory Direct for Industrial Pipeline SystemsNegotiableMOQ: 1 Ton

-

Custom Size 1.4529/N08367/N08926/S31608 Stainless Steel Pipes Manufacturer for Oil and Gas RefineriesNegotiableMOQ: 1 Ton

-

Efficient Heat Transfer Stainless Steel Pipes S31609/316H/347H/SUS34778 Factory Price for Thermal Power Plant Heat ExchangersNegotiableMOQ: 1 Ton

-

Food Grade SUS34779/304H/S30409/S321H Stainless Steel Pipes Factory Supply for Food and Beverage Processing LinesNegotiableMOQ: 1 Ton

-

Desalination Suitable Stainless Steel Pipes S32169/317L/S31703/S25073 Trusted Manufacturer for Desalination Plant PipelinesNegotiableMOQ: 1 Ton

-

Transport Grade 2507/1.4435/724L/316LMOD Stainless Steel Pipes Factory Made for Chemical Transportation TankersNegotiableMOQ: 1 Ton

-

Shipbuilding Grade Stainless Steel Pipes 174PH/SUS631/2205/F51 Direct Factory for Marine Propulsion SystemsNegotiableMOQ: 1 Ton

-

Renewable Energy Suitable SUS630/177PH/S31803/F53 Stainless Steel Pipes Custom Manufacturer for Solar Thermal ProjectsNegotiableMOQ: 1 Ton