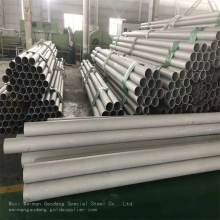

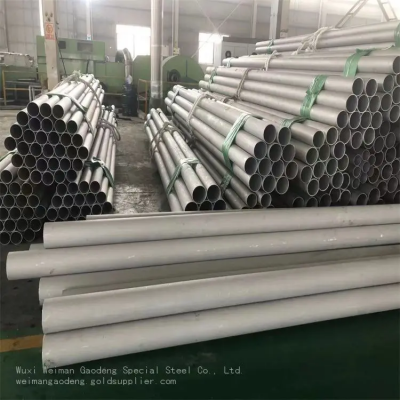

Chemical Resistant Stainless Steel Pipes SUS329J1/1.4460/254SMO/F44 Factory Supply for Chemical Storage Tanks

Product Overview

Our chemical resistant stainless steel pipes, including SUS329J1, 1.4460, 254SMO, and F44, are the ideal choice for chemical storage tanks. These pipes are meticulously crafted by our factory, Wuxi Weiman Gaodeng Special Steel Co., Ltd., a renowned manufacturer in the special steel industry since 2017. With a strong export record of US$5 Million - US$10 Million, we have established a global presence in markets across North America, South America, Europe, Asia, Africa, and Oceania.

Surface Treatment and Technique

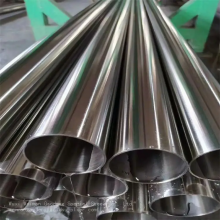

- Surface Treatment: The pipes undergo a polished surface treatment. This not only gives them an aesthetically pleasing appearance but also provides several functional benefits. The smooth surface reduces the adhesion of chemicals, minimizing the risk of corrosion initiation points. It also makes the pipes easier to clean, which is crucial in chemical storage applications where maintaining a clean interior is essential to prevent contamination.

- Technique: They are produced using the hot - rolled technique. Hot rolling enhances the mechanical properties of the pipes, making them more ductile and stronger. This process aligns the grain structure of the stainless steel, improving its overall integrity and resistance to external stresses. The hot - rolled pipes can better withstand the pressure and forces exerted by the stored chemicals in the storage tanks.

Shape and Standard

- Shape: The pipes have a round shape. The round shape offers uniform stress distribution, which is vital for containing chemicals under pressure. It also allows for efficient flow of chemicals within the pipes, reducing the risk of blockages and ensuring smooth operation of the chemical storage system.

- Standard: Our pipes comply with the ASTM standard. This international standard ensures that the pipes meet high - quality and safety requirements. By adhering to ASTM standards, we guarantee that our products are reliable and suitable for use in various chemical storage applications around the world.

Material and Chemical Resistance

- Material: The pipes are made of high - quality stainless steel. The specific grades, SUS329J1, 1.4460, 254SMO, and F44, are carefully selected for their excellent chemical resistance properties. These grades contain elements such as chromium, nickel, and molybdenum, which form a passive oxide layer on the surface of the pipes. This layer acts as a barrier, protecting the underlying metal from corrosion caused by a wide range of chemicals, including acids, alkalis, and salts.

- Chemical Resistance: They can withstand exposure to highly corrosive chemicals commonly stored in chemical storage tanks. For example, they can resist the corrosive effects of sulfuric acid, hydrochloric acid, and sodium hydroxide. This makes them suitable for use in industries such as chemical manufacturing, petrochemicals, and water treatment, where the storage of aggressive chemicals is a common requirement.

Company - Specific Advantages

- Customization and Value - Added Services: Our company specializes in high - precision special steel solutions. We offer customized materials to meet the specific requirements of our international customers. Whether it's a unique pipe diameter, wall thickness, or length, we can produce pipes according to your specifications. Additionally, we provide value - added services such as custom - cutting for plates (max thickness 120mm) and pipes (OD 20 - 1200mm), ensuring that you receive the exact products you need.

- Advanced Testing and Quality Assurance: We have advanced non - destructive testing (NDT) services in place. Ultrasonic Testing (UT) to EN 10228 - 3 can detect internal defects as small as 0.5mm, while Magnetic Particle Testing (MT) can identify surface cracks. Our testing facilities are certified by SGS and BV, ensuring that every pipe leaving our factory meets the highest quality standards.

- Rapid Logistics: With strategically located warehouses in Wuxi, we can ensure 48 - hour delivery to major Chinese ports. This means that you can receive your chemical resistant stainless steel pipes in a timely manner, reducing downtime and ensuring the smooth operation of your chemical storage facilities.

Applications

- Chemical Storage Tanks: As mentioned, these pipes are primarily used for chemical storage tanks. They provide a reliable and long - lasting solution for containing various chemicals safely.

- Chemical Processing Plants: In chemical processing plants, the pipes can be used for transporting chemicals between different processing units. Their chemical resistance ensures that the chemicals are transported without any risk of contamination or leakage.

- Water Treatment Facilities: In water treatment facilities, the pipes can handle the corrosive chemicals used in the treatment process, such as chlorine and fluoride. This helps in maintaining the integrity of the water treatment system and ensuring the quality of the treated water.

In conclusion, our chemical resistant stainless steel pipes SUS329J1/1.4460/254SMO/F44 offer a comprehensive solution for chemical storage and handling applications. With their excellent chemical resistance, high - quality manufacturing, and our company's advanced services, they are the perfect choice for international customers in need of reliable and durable pipes for their chemical storage tanks.

Send Inquiry to This Supplier

You May Also Like

-

Desalination Suitable Stainless Steel Pipes S32169/317L/S31703/S25073 Trusted Manufacturer for Desalination Plant PipelinesNegotiableMOQ: 1 Ton

-

Transport Grade 2507/1.4435/724L/316LMOD Stainless Steel Pipes Factory Made for Chemical Transportation TankersNegotiableMOQ: 1 Ton

-

Shipbuilding Grade Stainless Steel Pipes 174PH/SUS631/2205/F51 Direct Factory for Marine Propulsion SystemsNegotiableMOQ: 1 Ton

-

Renewable Energy Suitable SUS630/177PH/S31803/F53 Stainless Steel Pipes Custom Manufacturer for Solar Thermal ProjectsNegotiableMOQ: 1 Ton

-

Pharmaceutical Grade Stainless Steel Pipes F52/S32950/2507/S32750 Factory Supply for Pharmaceutical Fluid HandlingNegotiableMOQ: 1 Ton

-

Mining Grade S32760/F55/F60/S32205 Stainless Steel Pipes Factory Price for Mining Slurry Transport EquipmentNegotiableMOQ: 1 Ton

-

Aerospace Grade Stainless Steel Pipes SUS329J1/254SMO/F44/S31254 Professional Manufacturer for Aerospace Hydraulic TubingNegotiableMOQ: 1 Ton

-

Furnace Suitable 1.4547/XM19/S20910/316Ti Stainless Steel Pipes Factory Direct for High Temperature Furnace ApplicationsNegotiableMOQ: 1 Ton

-

Custom Length TP405 Stainless Steel Tubing Corrosion Resistant Industrial Application Stainless Steel PipeNegotiableMOQ: 1 Kilogram

-

High Temperature S40500 Seamless Tubing Precision Cut Stainless Steel Seamless PipeNegotiableMOQ: 1 Kilogram