Hot Selling Inconel 718 UNS N07718 Bar Super Alloy,rod,tube

Hot Selling Inconel 718 UNS N07718 Rod, Bar, TubeProduct Overview

Our Inconel 718 UNS N07718 wire, rod, bar, and tube are highly sought - after products in the global market. Inconel 718 is a nickel - chromium - iron alloy known for its outstanding combination of high - strength, excellent corrosion resistance, and remarkable creep and rupture properties at elevated temperatures. This makes it an ideal choice for a wide range of industries, including aerospace, chemical processing, and power generation.

Material Composition

Inconel 718 is composed mainly of nickel (50 - 55%), chromium (17 - 21%), iron (balance), along with significant amounts of niobium and molybdenum. The addition of niobium helps in precipitation hardening, which contributes to the alloy's high strength. Molybdenum enhances the alloy's corrosion resistance, especially in environments containing aggressive chemicals. Other minor elements such as titanium, aluminum, and carbon are also present in carefully controlled amounts to optimize the alloy's properties.

Product Forms and CustomizationRod

The Inconel 718 rods are manufactured with strict dimensional tolerances. They are available in different lengths and diameters, suitable for machining into various components. Whether you need rods for forging, machining, or other processes, our rods offer excellent workability and mechanical properties.

Bar

Our bars are available in a variety of cross - sectional shapes, including round, square, and hexagonal. They are produced using advanced manufacturing techniques to ensure consistent quality throughout the bar. The bars can be cut to specific lengths, and we can also provide custom - shaped bars according to your blueprints.

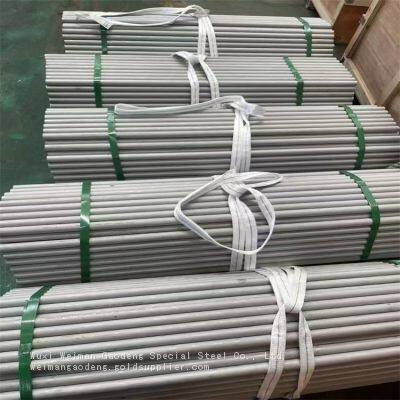

Tube

The Inconel 718 tubes are available in seamless and welded forms. Seamless tubes offer superior integrity and are suitable for high - pressure applications. Welded tubes, on the other hand, can be more cost - effective for certain applications. Our tubes come in different wall thicknesses and diameters, and can be customized in terms of length and end finishes.

Surface Treatment

All our Inconel 718 products undergo a polishing surface treatment. This not only gives the products an aesthetically pleasing silver color but also provides several functional benefits. The polished surface reduces friction, which is beneficial in applications where the product comes into contact with other components. It also helps to improve the corrosion resistance of the alloy by providing a smooth surface that is less likely to trap corrosive agents.

Performance and ApplicationsHigh - Temperature Performance

Inconel 718 maintains its strength and integrity at high temperatures, up to approximately 700°C (1292°F). This makes it an excellent choice for aerospace applications, such as turbine blades, engine components, and exhaust systems. In the power generation industry, it is used in gas turbines and steam turbines, where it can withstand the high - temperature and high - stress conditions.

Corrosion Resistance

The alloy offers excellent corrosion resistance in a variety of environments, including seawater, acidic solutions, and high - temperature oxidizing atmospheres. In the chemical processing industry, Inconel 718 is used for pipes, valves, and reaction vessels, where it can resist the corrosive effects of various chemicals.

Fatigue Resistance

Inconel 718 has good fatigue resistance, which is crucial in applications where the product is subjected to cyclic loading. For example, in the automotive industry, it can be used in engine components that experience repeated stress during operation.

Manufacturing and Quality Assurance

We are a professional manufacturer, Wuxi Weiman Gaodeng Special Steel Co., Ltd., established in 2017. Our company has a team of 11 - 20 experienced salespersons dedicated to serving our international customers. With an annual export share of US$5 Million - US$10 Million, we have a well - established production process and strict quality control system. Our products are manufactured in accordance with international standards and undergo comprehensive testing, including chemical analysis, mechanical property testing, and non - destructive testing, to ensure that they meet the highest quality requirements.

Our Inconel 718 UNS N07718 wire, rod, bar, and tube are reliable products that offer excellent performance and quality. Whether you are in the aerospace, chemical, or other industries, our products can meet your specific needs.

Send Inquiry to This Supplier

You May Also Like

-

Hot Selling Quality High Strength Super Alloy Seamless Pipe Incoloy 800 Alloy Tube/Alloy PipeNegotiableMOQ: 1 Ton

-

High Quality Haynes 230 282 242 188 Nickel Alloy Pipe With Cheap PriceNegotiableMOQ: 1 Ton

-

Wholesale High Performance Seamless Alloy Pipe Cobalt Alloy Haynes 25 Tube/Haynes188 PipeNegotiableMOQ: 1 Ton

-

Pure Ni, Nickel Alloy 201, Uns N02201, 2.4061 Nickel Alloy Seamless Steel Pipe Tube for Anti-Corrossion PartsNegotiableMOQ: 1 Ton

-

Nickel 200 201 Uns N02200 N02201 Sheets Plates Nickel-based Alloy Pipe ManufacturerNegotiableMOQ: 1 Ton

-

Nickel Alloy Steel Nickel 201 Alloy (UNS N02201) /2.4068 Seamless Pipe and TubeNegotiableMOQ: 1 Ton

-

Nickel 200 201 Seamless Tube N02200 N02201 Pure Nickel Tube Pipe for ElectroplatingNegotiableMOQ: 1 Ton

-

Pure Nickel Ni201 UNS N02201 Nickel Alloy Pipe Nickel Seamless TubeNegotiableMOQ: 1 Ton

-

Nickel 201、N02201 Custom Nickel Alloy Pipe Tube STM Standard Pipe Industrial ApplicationNegotiableMOQ: 1 Ton

-

High Quality Nickel Alloy Nickel 200/N02200 for Electronic Components Purity Nickel Alloy 201 PipeNegotiableMOQ: 1 Ton